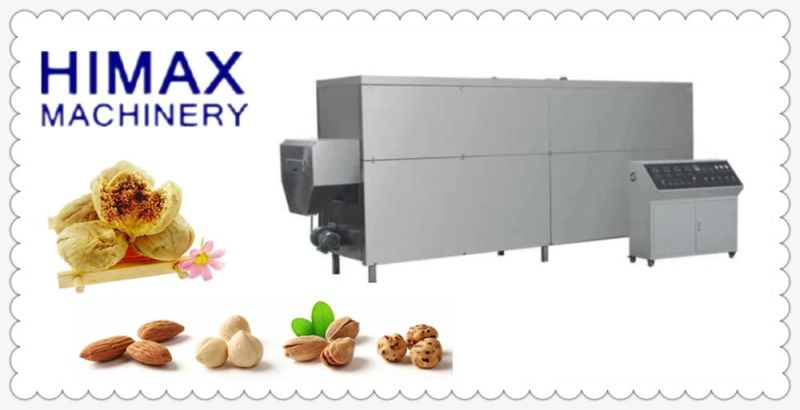

High Automatic Industrial Puffed Food Dryer

ZheJiang Kincess Innovative Materials Co., Ltd. / 2022-07-05

- After-sales Service:Online Surpport

- Warranty:1 Year

- Type:Dryer

- Voltage:220V,380V

- Power:60kw

- Customized:Customized

=== Base Info ===

- Model NO.:HM-20

- Service:After-Sale Service

- Material:Food Grade Stainless Steel

- Installation:Engineer′s Guidance

- Delivery Time:30 Days

- Weight:8t

- Brand:Himax

- Heating Method:Electric

- Heating Source:Elctricity

- Product Type:Dried Food

- Transport Package:Wooden Case

- Specification:14*1.6*2.2

- Trademark:Himax

- Origin:Shandong China

- HS Code:8438800000

- Production Capacity:200 PCS, Month

=== Description ===

Basic Info.

Model NO. HM-20 Service After-Sale Service Material Food Grade Stainless Steel Installation Engineer′s Guidance Delivery Time 30 Days Weight 8t Brand Himax Heating Method Electric Heating Source Elctricity Product Type Dried Food Transport Package Wooden Case Specification 14*1.6*2.2 Trademark Himax Origin Shandong China HS Code 8438800000 Production Capacity 200 PCS/ MonthProduct Description

High Automatic Industrial Puffed Food DryerIntroduction1. multilayer dryer is one of the most important machine in puffed food production line. Its effect is drying semi-finished products. Drying process can control puffed food's moisture, and make them crispy. It can adjust puffed food's property and extend their expiration date. Electric oven can be used in almost all of puffed food manufacturing processes, such as puffed snacks, pet food, fish feed, textured soy protein, modified starch, man-made rice etc.

Our electric ovens are mainly divided to 3 type (by layers quantity)---3 layers, 5 layers and 7 layers. It depends on different food varieties and output requirement.

2. multilayer dryer Features

2.1 Oven mesh operating speed can be controlled by inverter, which can control the drying time.

2.2 Our ovens are equipped with full automatic visible temperature control system. You can set different temperatures according to different food and requirement.

2.3 Oven mesh can be 1 or 2 layers. Its size, its fineness can be customizable.

2.4 multilayer dryer occupies smaller area, which can save your investment.

2.5 Heating is uniform, thermal efficiency is high.

2.6 Mesh, guard plate is made of stainless steel, which is clean and easy to be cleaned.

3. Parameters

| Model | Installed Power (kw) | Actual Power (kw) | Size (mm) |

| HM-3-5 | 27 | 18 | 5200x1300x2200 |

| HM-3-8 | 45 | 35 | 8400x1300x2200 |

| HM-5-5 | 45 | 35 | 5200x1300x2200 |

| HM-5-8 | 60 | 50 | 8400x1300x2200 |

| HM-7-5 | 66 | 50 | 5200x1300x2600 |

| HM-7-8 | 88.2 | 75 | 8400x1300x2600 |

Packing and delivery:

Packing: inside plastic bag, outside wooden case(Based on the customers' need adopt the wooden case or wooden pellets, etc.) for multilayer dryer

Transportation: shipping, train, express or upon clients' demands for multilayer dryer.

Services for multilayer dryer

Before sale services for multilayer dryer

1.Provide the free consultation of the equipment

2.Provide the standard device and the flow chart

3. According to the clients'special requirement, offering the reasonable plan and free design helping to select the equipment.

Services during the sales for multilayer dryer

1.Help client design the factory and offering professional advice, free engineering drawing for the factory layout.

2.Welcome to visit our factory or the domestic clients' factory.

3.Inspect the machine before leaving the factory.

After sale services for multilayer dryer

1. Oversea install and debug the equipment.

2. Train the first-line operator.

3. Provide the basic formula

4. Operation/ Service/ Maintenance Manual: Provided In English.

5. We will provide 1-2 engineer to the client's factory for the installation and teach totally in 10 days. The client need provide room, food, round-trip transportation, visa and a nominal $50 daily subsidy per person.

Why choose us

1 With the function drying, heating, cooking, sterilization, unfreezing, dehydration, inactivation etc.

2 PLC auto or button control system, support data saving, outputting, and printing

3 Microwave power stepless adjustable, temperature and humidity chain intelligent control

4 Speed can be adjusted.

5 The machine size can be adjusted according to users' workshop area.

6 Fast continuous production, which is uniform and thorough.

7 The perfect mechanical and electrical integration design, the real-time monitoring of multiple sensors, safe and reliable.

8 Adopt food-grade materials.

9 Production can be monitored, quantified and controlled.

Our Company

Jinan HIMAX Machinery Co; Ltd. is a professional supplier of food processing machines. Our company's Motto is: "Technology Makes Easy". We offer to cooperate with our customers for mutual and beneficial development.

We have a group of experienced experts and outstanding engineers who do provide the professional service delivery and installation. Based on the clients specific requirement, we also design and produce the machines to order. We have through the years established good working relationship with some reputable organizations both at home and abroad with outstanding goodwill.

Our main products line include food extrusion machine, soya meal/meat processing machines, industrial micro wave oven, packaging machines, rice cake machine etc... Most importantly, we also provide formulas, technology supports, machine inspection service, etc.

All inquiries are welcome.

Certificates

Our Service

1. Free consultation service before, during, and after sales;

2. Free project planning and design services;

3. Free debugging of equipment until everything is functional;

4. Free management of equipments' long distance shipping;

5. Free training of equipment maintenance and operating personally;

6. Free new production techniques and formulas;

7. Provide 1 year complete warrantee and lifetime maintenance service;

Contact Us

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23