Extrusion Equipment of Jacket Pipe for Thermal Insulation Pipe

=== Base Info ===

=== Description ===

Basic Info.

Model NO. PE-110/600 Assembly Structure Integral Type Extruder Screw Single-Screw Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Don′t Exhaust Automation Automatic Computerized Computerized Transport Package Standard Pakage Specification 25m Trademark HSD Origin Qingdao, China HS Code 8477209000 Production Capacity 1000 Set/YearProduct Description

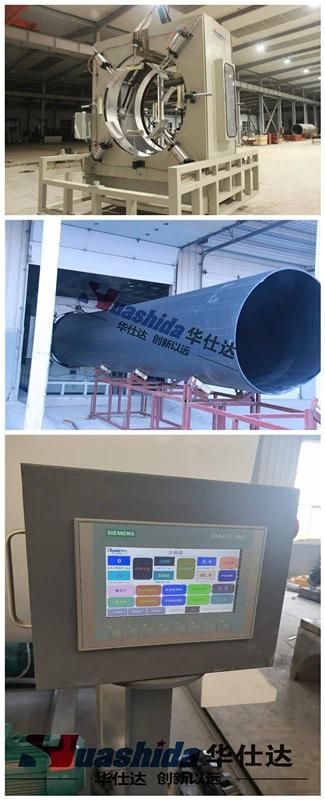

Extrusion equipment of Jacket pipe for thermal insulation pipePE series Extrusion equipment of Jacket pipe for thermal insulation pipe designed by absorbing the tube extrusion developed technology from German and inproved by Qingdao Huashida Machinery Co. Ltd..

The Extrusion equipment of Jacket pipe for thermal insulation pipe is an intergration design composed by extrusion, vacuum calibrating, cooling, pulling, cutting, stacker. Great performance in automatic operation, extrusion capacity, steady and sevice life etc. Especially compared with the line use internal pressure method, vacuum calibrating method is much better than in for stiffness, pressure resistance and surface smooth.

Compared with inflating method (internal pressure method)

1) For 24 hours working, it reduces 2-3 workers for each shift.

2) There is much waste pipe and material, no need workers to crush waste material.

3) High-effeciency. Take Dimater 960mm as an example, Output is approximately 60 pcs of 11.6meters pipe, it is much higher output than that of inflating method.

4) Pipe wall is average and smooth, to reduce waste of raw material, and pipe thickness is adjustable.

5) No need trim edge, once forming.

Extrusion equipment of Jacket pipe for thermal insulation pipe is the most advanced and popular machinery in the wold.

The composition of the Extrusion equipment

1. Single screw extruder

2. Die-head

3. Vacuum forming tank

4. Caterpillar Haul-off machine

5. No-Dust Cutter

6. Controlling system

7. Discharging fram

Techincal parameters

| Style | PE-110/600 | PE-655/1372 | PE-960/1680 |

| Main Extruder | SJ-75/33 | SJ-120/33 | SJ-150/33 |

| Pipe diameter | Φ110-600mm | Φ655-1372mm | Φ960-1680mm |

| Capacity | 250-350kg/h | 700-900kg/h | 800-1200kg/h |

| Installed power | 160kw | 440kw | 580kw |

| Length | 28m | 32m | 45m |

Qingdao Huashida Machinery Co., Ltd was established in 2003 and has focused on plastic pipe production line and joints of plastic pipes and 2PE 3PE pipes for over 14 years, we are a private high-tech enterprises integrated by R&D, manufacturing, selling, service and trading.

We are always concentrating on research and development of plastic extrusion equipments, tightly cooperating with Tsinghua University, Beijing University of chemical technology, South China university of technology and some other colleges and scientific research institutions. Meanwhile, by absorbing advanced technology home and abroad, we have been one of the top manufacturers of plastic extrusion machines in China, especially of PE insulation jacket pipe extrusion line, PE PP sheet extrusion line, and PE hollow wall spiral pipe production line.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23