Wood Plastic Composite Wall Panel/Window Profile/ WPC Cladding Production Line

Ningbo Zhaoke Int'l Imp. & Exp. Corp / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

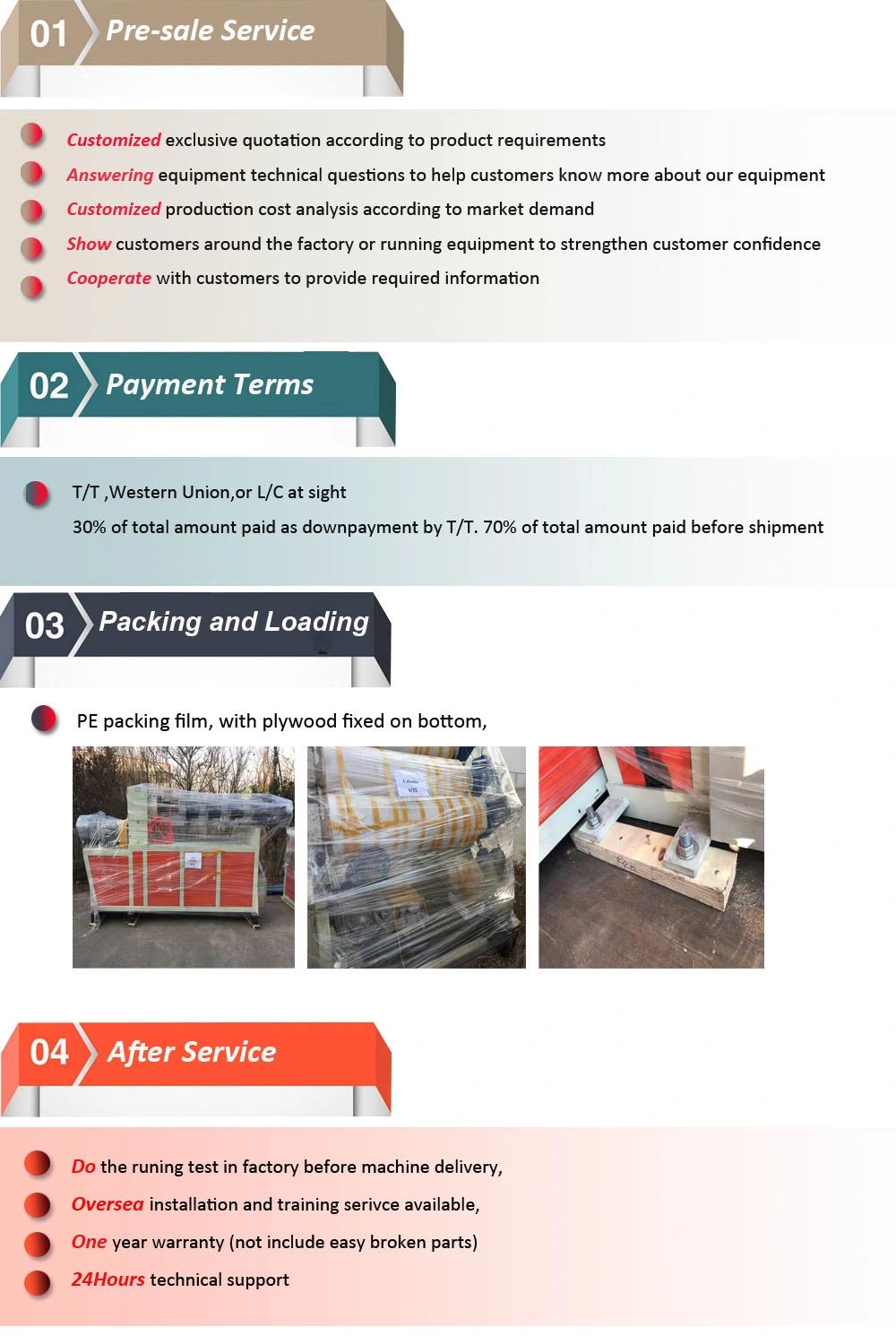

Model NO. SJSZ55/65 Customized Customized Condition New Raw Materials PVC Powder Resin with Wood Powder Equipment Color as Request Number of Screw 2 Pieces Screw Effective Length 1440mm Gearbox Hardened Gears Temperature Heating Range 60ºC-300ºC Heater Cast Aluminum Equipment Centre Height 1000mm Transport Package Wooden&Stretcth Film Specification 200mm~800mm Trademark SUKE MACHINERY Origin Qingdao, China HS Code 84778000 Production Capacity 100sets/YearProduct Description

---Welcome To SUKE Extrusion - High Cost-Effective Extruder Manufacturer---Wood (WPC) PE PP PVC Plastic Composite Window Profile/Ceiling/Board/Wall Panel/Edge Banding/Sheet Extrusion Extruding machine Production linePE/PP/PVC WPC profile/ Panel/Board Extrusion Line

Advantages:

Unique bi-metallic design of the barrel & screw for WPC profile extrusion ensure good plasticization and high wear-resistant;

Using Germany and domestic high-quality steel for vacuum calibration and cold-pushing die head ensure rapid cool, and achieve efficient and stable production;

Calibration table with pressure and water flow inspection makes a precise control

Haul-off adopts an independent motor driving to ensure stable and reliable traction;

Saw cutter leads fast cutting, smooth incision and accurate length, collecting and re-use saw dust;

Combined type haul-off and cutter design is more compact and economical;

Matching with punching, embossing, brushing, sanding, lamination, hot stamping, printing machine achieves good synchronize and automatic control.

Wood-plastic products is as a substitute for traditional wood products, greatly reduce the demand for wood. According to the demand, SUKE specially designed the calibration forming technology for PVC wood plastic foam, low foam / no foam and cold push solution for PE/PP wood plastic. To pursue a longer using life of wood products, the surface of WPC products with a protective layer through co-extrusion technology comes into being. In addition, we are devote to the provision of the turn-key solution, including upstream machine, such as wood crusher, pulverizer and drying equipment, WPC composite mixing & pelletizing system, and downstream, such as embossing, brushing, sanding, lamination, hot stamping transfer, printing, Waste crushing, grinding and recycling equipment for different wide products.

Application:The most widespread use of WPC is in outdoor deck floors, but it is also used for railings, fences, landscaping timbers, cladding and siding, park benches, molding and trim, window and door frames, and indoor furniture.Qingdao Extrusion Machinery Co., Ltd. is a High-Tech company, which is composed of well-experienced team in R & D design, manufacturing technique, sales service and bases on Single/Twin screw extruder industry more than 18 years.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23