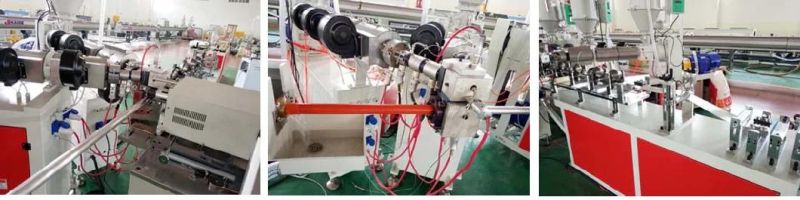

Under Floor Heating Pex-Al-Pex Pipe Making Machine/Pipe Production Line/Pipe Extruder

Nanjing Lite Hydraulic Technology Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

The pexb-al-pexb pipe production line includes:

Features of the PEXb-AL-PEXb pipe extrusion line:

Aluminum pipe forming device:

(1)PEXb-AL-PEXb pipe machine adopts high precision aluminum tube forming technology

(2)The ultrasonic welding aluminum tube has precise dimensions and good roundness.

(3) All the Al tube forming tools are produced by our own imported high precision CNC machinery.

Extruder&Co-extrusion die head:

(1) High efficient extruder equipped, which is special designed for high speed PEXb AL PEXb pipe making.

(2) Screw and barrel are independently developed and designed by KAIDE technical team, according to the performance and technology of the processed pexb materials, with nitriding thickness 0.5mm-0.7mm.

(3)Own-patented multi-layer co-extrusion die head technology, each layer thickness can be adjusted freely.

(4)The unique screw structure design avoids the pre-crosslinking of the PE-Xb material in the barrel, and the finished PEXb-AL-PEXb pipe surface is smooth and look nice.

Automatic PEX-AL-PEX pipe coiler

(1) The coiler adopts Siemens (Siemens) touch screen operation interface, intelligent operation, simple and easy to learn;

(2) Parameters such as coiling length, coiling diameter, tension value, and reel origin can be set online, and the current coiling length and wiring can be displayed in real time Location, etc.

(3) It can realize remote control function

(4) The control system support multiple languages, and local language versions can be added according to the actual needs of customers

(5) Including Autonics brand sensor for Broken pipe detection. When the sensor detects the end of the pipe, it sends a signal to the PLC control system, and the reel automatically stops.

(6) The adjustment scale of reel width and inner diameter of reel, laser marking, convenient, intuitive and fast adjustment.

PLC controlling system

(1)Synchronous control of Extruder and the downstream equipment, such like gravimeter system, haul-off machine, etc.

(2)Intelligent and easy to learn for operator. Kinds of information such as temperature, electricity, melting pressure, can be showed on screen.

(3)Alarm reminder. Programmable amd settable alarming and protection function at all levels.

(4)Remote control system for machine fault analysis and problem solving.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23