Vacuum Falling Film Multi-Effect Evaporator for Chemical Pharmaceutical Food Cosmetic

Zibo Tianheng New Nanomaterials Technology Co., Ltd / 2022-07-05

- Type:Dehydrator

- Voltage:380V

- Power:1.5KW

- Customized:Customized

- Evaporating Temperature:Low Temperature Under Vacuum Condition

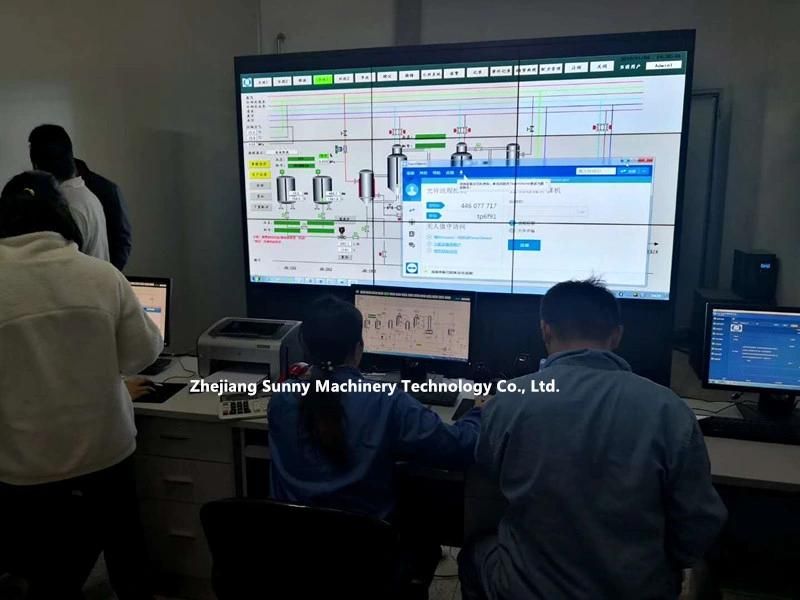

- Automatic Control:Complete with PLC Control System

=== Base Info ===

- Model NO.:MEA

- Washing and Cleaning:CIP Washing Head with Rotation

- Surface Treatment:Mirror Polishing

- Standard:GMP

- Effect:Single-Effect to Five-Effect

- Transport Package:Wooden Case

- Specification:1000L-6000L

- Trademark:Zhejiang Sunny Machinery,OEM

- Origin:Wenzhou China

- HS Code:8419899090

- Production Capacity:5 Sets,Year

=== Description ===

Basic Info.

Model NO. MEA Washing and Cleaning CIP Washing Head with Rotation Surface Treatment Mirror Polishing Standard GMP Effect Single-Effect to Five-Effect Transport Package Wooden Case Specification 1000L-6000L Trademark Zhejiang Sunny Machinery/OEM Origin Wenzhou China HS Code 8419899090 Production Capacity 5 Sets/YearProduct Description

Applications

This evaporator is widely used in pharmaceutical, food, chemical industry, it also can be used for industry waste water in these industry, It is specially used for sensitive temperature product, this machine can be operated under vacuum condition, it can evaporate quickly, save energy, operation cost is low, and it can keep the original feature of the raw material.

Working principle

The principle of film falling evaporator, the liquid from up parts flow to down parts by pipe, the liquid can be distributed uniformly, and it flow from up parts to down parts by gravity and vacuum, it is heated by medium steam during operation, then it will became into steam and liquid, the steam and liquid will be separated in the chamber, the steam will be cooled by condenser(single effect) or used for heating steam, at last the liquid will be discharged from the chamber.

Main features

1. The principle of film falling evaporator, the liquid from up parts flow to down parts in pipe, the liquid can be distributed uniformly, and it flow from up parts to down parts by gravity and vacuum, it will be sticky during evaporation, and you can get the concentrated liquid at the bottom, the falling film evaporator can evaporate the high density and viscosity(scope from 0.05-0.45ns/square meter) material.

2. The solution flows like film in the single type evaporator, so the heat transger coefficient is high.

3. The liquid in the pipe flow very quickly, so it can be metamorphosies easily, suitable for sensitive product.

4. The retention volume of liquid is small, the falling film evaporator can adopt fast operation, according to changes of energy supplying, vacuum degree, quantity of material feeding, density.

5. Due to fluid flows only under gravity, not pushed by temperature difference, the evaporation can be operated in the low temperature.

6. Falling film evaporator is suitable for foaming material, the liquid can be evaporated in the heating tube like film, forming separation of liquid and vapor. Meanwhile, at the bottom, most liquid will be pumped away, only leaving small part of liquid and the second steam to separating chamber for separation. The liquid doesn't make the big hit in the process, avoiding the formation of foam.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23