Automatic Power Control 300W Laser Welding Machine for Metal Sign Welding

Kunshan Grepak Packing Materal Co., Ltd. / 2022-06-23

- Warranty:2 Years

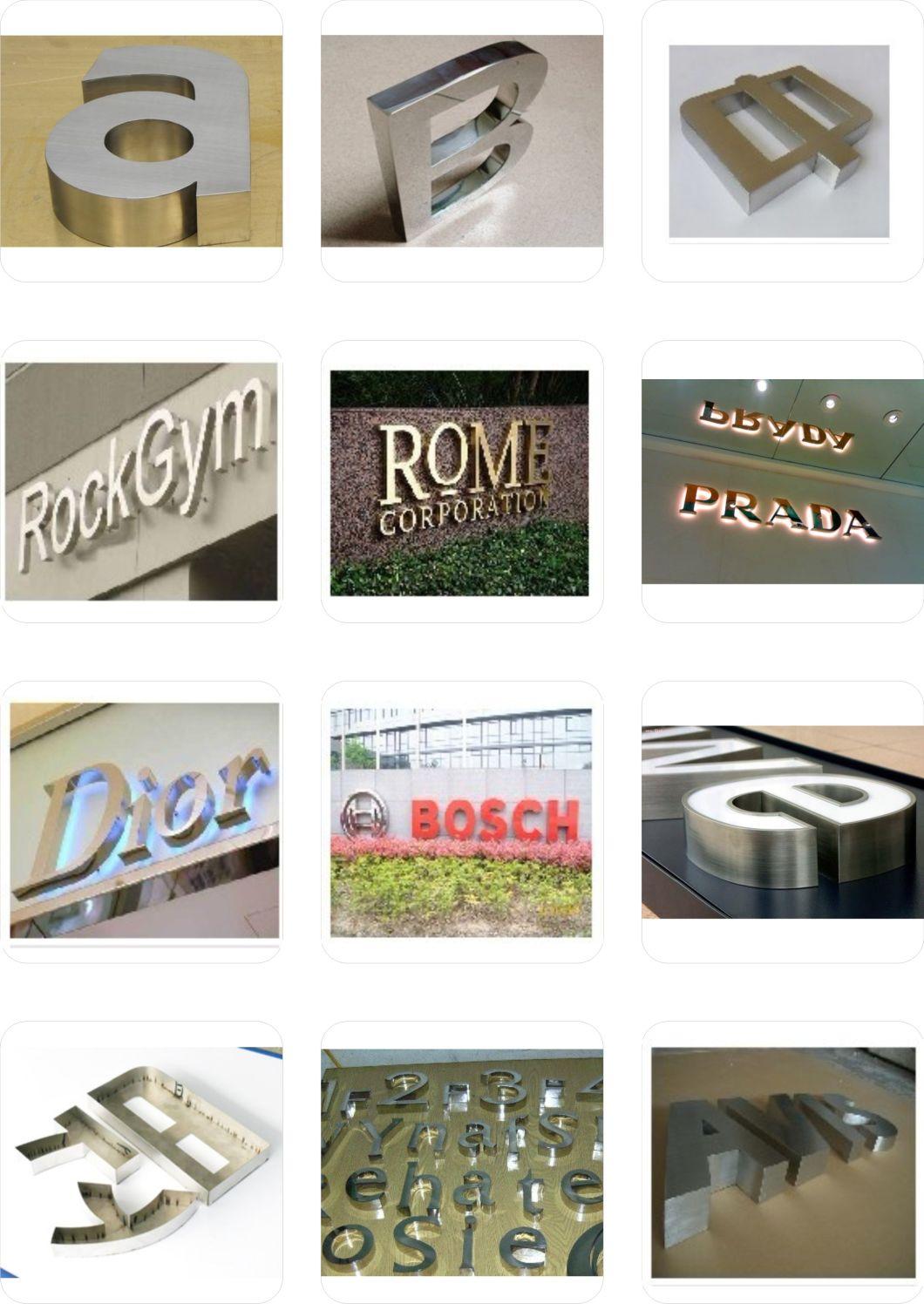

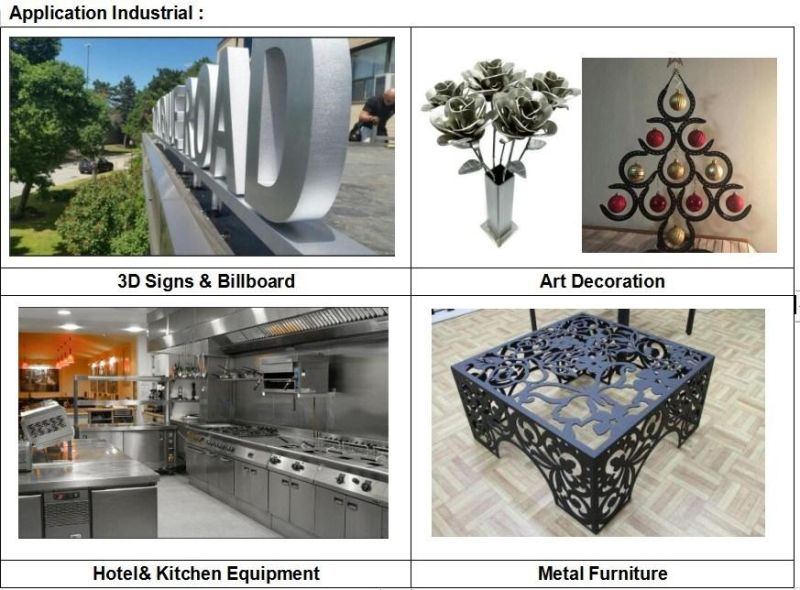

- Application:Sign & Advertising

=== Base Info ===

- Model NO.:BHJ-300W

- Technical Class:Pulse Laser

- Control:PLC

- Power Density:Deep Fusion Welding

- Laser Classification:YAG Laser

- Type:YAG, Laser Spot Welder

- Cooling Way:Water Cooling

- Style:Portable

- Frequency Range:Intermediate Frequency

- Electric Current:AC

- Work Form:Laser Welding Machine

- Transport Package:Plywood Package

- Specification:300W

- Trademark:BYT

- Origin:China

- HS Code:8515809090

- Production Capacity:200sets,Month

- Package size per unit product:2.10cm * 1.70cm * 1.50cm

- Gross weight per unit product:500.000kg

=== Description ===

Basic Info.

Model NO. BHJ-300W Technical Class Pulse Laser Control PLC Power Density Deep Fusion Welding Laser Classification YAG Laser Type YAG, Laser Spot Welder Cooling Way Water Cooling Style Portable Frequency Range Intermediate Frequency Electric Current AC Work Form Laser Welding Machine Transport Package Plywood Package Specification 300W Trademark BYT Origin China HS Code 8515809090 Production Capacity 200sets/MonthPackaging & Delivery

Package size per unit product 2.10cm * 1.70cm * 1.50cm Gross weight per unit product 500.000kgProduct Description

Automatic Power Control 300W Laser Welding Machine for Metal Sign WeldingApplication field :

Advertising laser welding machines have small welding spots, joint firmness for metal word connection, widely used in signage making, metal word production and advertising display production company.

Feature:

1. Long warranty: one year for the whole machine, two years for the main board, motor and driver, except for wearing parts. In addition as wearing parts provide another 5 positioning needles, 2 protective lenses and 1 xenon lamp. These wear parts can be used for at least two years.

2. Ensure the actual working effect, strong power, eliminate light decay, can achieve fast and constant power welding.

| Model | Power | Depth of fusion(mm) | Welding thickness (mm) | Refer metal |

| BHJ-300W | 300W | 1.5 | 0.1-2.5 | SS |

| BHJ-500W | 500W | 2 | 0.1-3 | SS |

4. Famous brand high-power water chiller, the internal compressor made by Panasonic or Sony. 1P water chiller up to 1.5P and 2p water chiller up to 2.5P.

5. Xenon lamp, foot pedal all adopt imported accessories, in order to ensure the stability of the equipment working for a long time.

6. Double optical paths welding machine, with Japanese technology as the hand-held welding gun and domestic top-quality fiber and patented technology.

Technical data:

| Model | BHJ-300W Single | BHJ-300W Double | BHJ-500W Single | BHJ-500W Double |

| Laser power | 300W | 300W | 500W | 500W |

| Laser wave length | 1064nm | 1064nm | 1064nm | 1064nm |

| Monopulse max power | 110J | 110J | 190J | 190J |

| Laser Welding Depth | 0.1-2.5mm | 0.1-2.5mm | 0.1-3mm | 0.1-3mm |

| Pulse width | 0.1-20ms | 0.1-20ms | 0.1-20ms | 0.1-20ms |

| Laser welding frequency | 1-50Hz | 1-50Hz | 1-100Hz | 1-100Hz |

| Laser spot size adjusting range | 0.2-3.0mm | 0.2-3.0mm | 0.2-3.0mm | 0.2-3.0mm |

| Total power | ≤7.5KW | ≤7.5KW | ≤16KW | ≤16KW |

| Water chiller | 1P | 1P | 2P | 2P |

| Working voltage | 220V±10%/50Hz/1P/40A | 220V±10%/50Hz/1P/40A | 380V±10%/50Hz/3P/40A | 380V±10%/50Hz/3P/40A |

| Working table size | 1000*1500mm | 1000*1500mm | 1000*1500mm | 1000*1500mm |

| Sight positioning | CCD synchronism high definition camera | CCD synchronism high definition camera | CCD synchronism high definition camera | CCD synchronism high definition camera |

| Laser device vertical travel | ≥200mm | ≥200mm | ≥200mm | ≥200mm |

| Laser device horizontal direction | 200-800mm | 200-800mm | 200-800mm | 200-800mm |

| Length of optical cable | ≥5m | ≥5m | ||

| Overall size(m) | 0.78*0.75*1.15 1.5*1*0.72 | 0.78*0.75*1.15 1.5*1*0.72 | 0.78*0.75*1.15 1.5*1*0.72 | 0.78*0.75*1.15 1.5*1*0.72 |

| Net weight(kgs) | 240 | 280 | 360 | 400 |

| Package size(m) | 1.65*0.85*1.35 (1.9cbm) | 1.65*0.85*1.35 (1.9cbm) | 1.65*0.85*1.35 (1.9cbm) | 1.65*0.85*1.35 (1.9cbm) |

| Gross weight(kgs) | 280 | 310 | 400 | 440 |

Frequently Asked Questions:

1. How to choose a suitable welding machine?

1) The client's industry: if it is an advertising industry, it is ok to recommend our advertising type. If the client is engaged in other industrial industries and the welding workload is very heavy, he can purchase our industrial type.

2) Thickness of welding: Welding machine has two parameters: depth of fusion and thickness of welding. Depth of fusion refers to the depth of welding fusion.Welding thickness refers to the thickness of the plate can be welded firmly.For example, the advertising industry generally will not weld thoroughly, which will affect the appearance. Therefore, to weld the thickness of 2.5mm, 300W is enough, and the depth of fusion can reach 1.5mm, so that the welding can be firm.

2. What is the purpose of holding a welding gun?

The handheld welding gun is mainly used for welding larger objects, such as advertising industry welding word, can weld 2-3 meters of word, can also be used to seal the word edge.

3. What is the difference between welding depth and fusion depth?

Welding fusion depth and welding thickness concept is different, welding depth refers to the full welding thickness, welding thickness refers to the maximum thickness of the material can be welded, like in the advertising industry generally will not be used full welding.

- What metal is the YAG laser welding machine mainly used for? Can it weld aluminum?

- The main welding stainless steel, but also welding galvanized sheet, titanium plate, and carbon steel plate, copper can not be welding.When welding galvanized sheet, the same power than the welding of stainless steel to reach the depth of fusion is less, because there are also reflective.YAG can be welded with aluminum, but it is not recommended, because aluminum has strong reflective characteristics, so the minimum 500W can be welded, and must be pure aluminum, not aluminum stip.The welding depth of 500W is 0.7mm, and the welding thickness is 1.8mm. Because the welding is not very firm, the words that are too big will be opened.

1) During use, pure water must be used, otherwise scale may easily occur in the crystal and damage the luminous effect. In addition, the replacement of pure water is generally 20 days per time.

2) Avoid too much vibration, which will affect the internal light path and destroy the light effect

3) Keep the protective lens clean and wipe with alcohol is recommended.It is not recommended to use cotton wadding directly because it will drop cotton wadding.

5. Do I need to buy more accessories when purchasing laser welder?

When the laser welding machine is sold, the wearing parts we provide can be normally used for two years, and you can no longer buy other parts.If necessary in the later stage, we will directly express to you .

How about your after-sale service?

We have a special English after-sales staff who will contact you in advance before you receive the machine, so that you can teach you how to install and use the machine after you receive it.In addition, you can also contact us at any time during the use.

6. I see that other manufacturers have equipment with large countertops. Can you make them?

Yes, we can also make a welding machine with a large working platform. The working table is 2100*1700mm and the cost is increased by 250 USD. However, the packaging volume is changed from 1.9CBM to 3.1CBM, which increases the packaging volume and increases your import freight, customs clearance fee and workshop floor space.

Why Choose us

Company Experience

- Founded in 1996, with registered trademarks "BAOYUANTONG" and "BYT".

2.Own more than 30 patents for invention, utility model and design.

3.Passed the "SGS certification" for 9 consecutive years, and all products have obtained the " Europe CE certification"

4.Exported to over 150 countries including the North America, Europe, South America, the Middle East,and have more than 2000 clients.

5.Provide one-stop procurement ,let customer's purchase more efficient and safety.

6.According the customer different requirements ,provide equipment customized solved plan and sample making .

1.Technical people have professional english ability and directly with customer communication.

2.24H/7D on line service , when you need we all will be here .

3.Before delivery , accept the international third party finish inspection .

4.Regular return visits to customers for technical guidance, and get high praise from customers.

5.For the products making , have professional technical engineer provide process guide .

Various Training Service

1.Provide U disk with detailed operation manual and video.

2.Via on line chat way service(QQ,whatsapp,wechat) for customer in any time.

3.Via teamviewer remote control software to provide on line guidance.

4. Customer come to our factory for learning how to operate the machines.

5.Engineer can go aboard for training if customer needed.

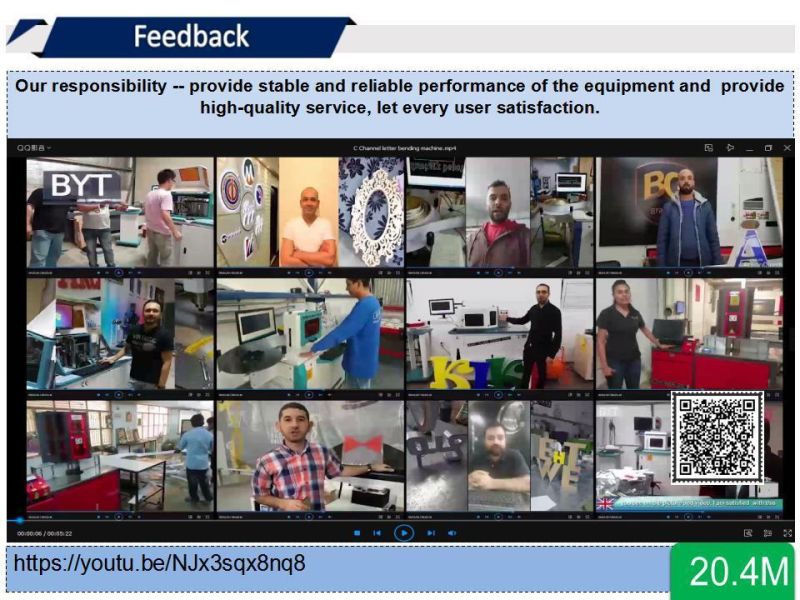

3.Buyer Feedback

Our responsibility -- provide stable and reliable performance of the equipment and provide high-quality service, let every user satisfaction. (Click the picture ,listen user's voice)

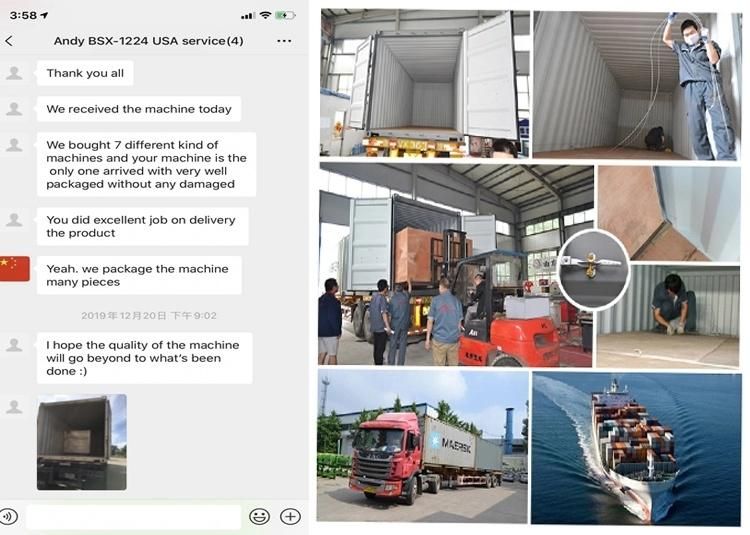

4.Package&Delivery

- After the completion of machinery production, the factory inspectors shall check and put the equipment into storage.Before the delivery of the equipment, the after-sales engineer shall conduct secondary inspection and ensure the quality of the machine meets the customer's requirements

2.Clean the whole machinery , protect the parts that need oil, and check the related parts again .

3. Anti-collision package edge: All parts of the machine are covered with some soft materials.

Whole film packaging machine: Avoid all damage that may occur during delivery. Then we will cover the plastic package tightly to ensure that the soft material is covered intact, also avoiding water and rust.

4. Fumigation wooden box:Our wooden box is fumigated, do not need to check the wood, saving the transport time and money.

5.Company Information

1.SHANDONG YUANTONG CENTURY INTELLIGENT TECHNOLOGY CO.,LTD This factory build in 1996, mainly producer vacuum forming machine ,vacuum press ,CNC router ,laser machine and channel letter bending machine ,the products export to more than 152 countries and get CE ,FDA, SGS certification , service more than 2000 customers

2.Customer Visiting

Our factory located in No.2999,2nd Industry Street, Weicheng ED-Zone, Weifang City Shandong Province China , Every year, we receive different countries customers to visit and study. Here, customers can have more real understanding of our production capacity, product quality and service, as well as better understanding of the work and operation of the equipment. Looking forward to your visiting in near future.

3.Exhibition and B to B platform

Since 2009 ,we take part in the different city's related fair ,and also go to abroad take part in exhibition and meet customer ,build cooperation relationship

4.Company Activities

We have a "unity, friendship, integrity, hard work" team, through the rich and colorful corporate activities, we feel everyone's passion, dedication and cohesion, we always believe that because of such an excellent team, will win more and more customers .

CE SGS Certification High efficiency 300W 500W stainless steel metal laser welding machine

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23