High Capacity Textured Soybean Protein Food Extruder Machine

AIRMAX AL CO., LIMITED / 2022-07-05

- Certification:CE, ISO9001

- Power Source:Electric

- Process:Thermal Processing

- Automatic Grade:Automatic

- Application:Ice Cream, Candy, Chocolate, Popcorn, Chips, Biscuit

- Customized:Customized

=== Base Info ===

- Model NO.:KS-70

- Voltage:220V,50Hz 380V,50Hz

- Warranty:1 Year

- Weight:1500kg

- Motor Brand:LG,Siemend,Chinese Brand

- Transport Package:Wooden Case

- Specification:26000*25000*3000mm

- Trademark:Keysong

- Origin:Shandong China

- HS Code:8438800000

- Production Capacity:50et,Month

=== Description ===

Basic Info.

Model NO. KS-70 Voltage 220V/50Hz 380V/50Hz Warranty 1 Year Weight 1500kg Motor Brand LG/Siemend/Chinese Brand Transport Package Wooden Case Specification 26000*25000*3000mm Trademark Keysong Origin Shandong China HS Code 8438800000 Production Capacity 50et/MonthProduct Description

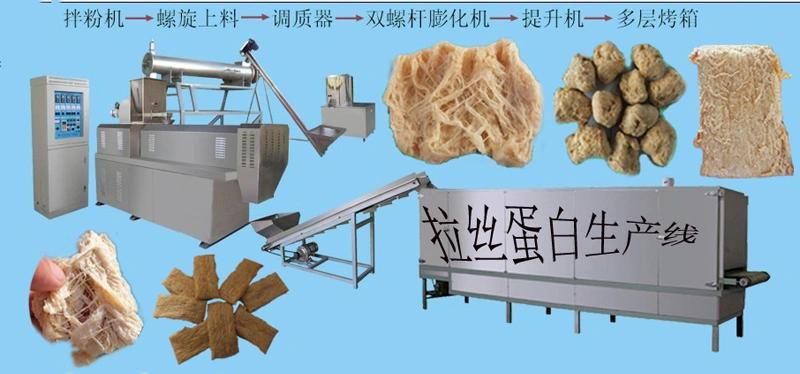

High capacity Textured soybean protein food extruder machine

I. Description

Extrusion textured soy protein machine is developed and manufactured on the basis of our experience combining with the advanced machines from foreign countries. This line takes

soybean meal and peanut meal as main raw materials. After milling, mixing, extruding and cutting, the meal becomes layer fiber structure. With high nutrition, the finished products look and taste like meat, absorb oil and water easily, no cholesterol and animal fat, so it is widely used in meat products industry, fast food production, deepfreeze food production and all kinds of vegetarian snacks and food.

Textured or texturized vegetable protein (TVP), also known as textured soy protein (TSP), soy meat, or soya meat, a meat analogue or nutritious meat extender is made through a process known as extrusion cooking with defatted soy flour as raw meterial.After the soya protein food is extruded from the dies of extruder plant the food is slicedinto granules, flakes, chunks, nuggets, goulash, steatoceles (schnitzel), etc. by revolving knives, and then are dried in a rotary dryer.

Textured Soya Protein Machine can produce the product with high nutrition, the meaty state and taste. Meanwhile it does not include the cholesterol and the animal tallow. It has the following features such as oil-absorbing, water-absorbing, ardor-absorbing and can be used in all kinds of professions

1. Raw Materials:

Soybean Meal, Peanut Meal etc.

2. Products:

oya Nugget with Different Shapes

3. Capacity:

120-150 KG/H, 200-250KG/H, 300-400KG/H

4. Flow Chart:

Fried Type: Mixing -Extrusion -Air Conveying -Baking

5. Voltage:

380V/50HZ/Three Phase, 220V/50HZ/Single Phase or Change As Rquired

6. Machines Materials:

All the machines are made by food grade stainless steel.

a. The screws are made by alloy steel (38CrMoAL) and special craft by nitriding process, The HRC hardness is around 60---62, it has good self-cleaning ability and does not need to discharge or clean the barrel and screw, when roasting or replacing of materials.

b. The extrusion barrel is constructed of carbon steel, is made by #45 steel, stainless steel coating.

c. The gearbox has automatic lubrication function, with extends gear life.

d. Cutting knife fixed in the die head seat, rotary cutting by V-belt drive.

e. SIEMENS(CHINA) brands electronic parts used in the controller box, make sure the extrusion process perfect.

f. Main Motor from SIEMENS(CHINA), ensure its powerful extrusion and excellent performance.

7. Technical Parameters

Model | Installed Power | Power Consumption | Output | Size(L×W× H) |

MT-65 | 85kw | 60kw | 120-150kg/h | 13000x1200x2200mm |

MT-70 | 92kw | 64kw | 200-250kg/h | 20000x3500x4300mm |

MT-85 | 120kw | 84kw | 300-400kg/h | 20000x3500x4300mm |

Every machine is packed with great care and tough material. It is packed with cling films first and then film bags. At last, it is packed with wooden case which is reinforced with the iron bar on the top and bottomWith this kind machine, all our laser machine can protect well during long trip by sea or by train.We can transport machine by boat or by training, according to your requirement.

9. Our Service

1. Free consultation service before, during, and after sales;

2. Free project planning and design services;

3. Free installation and commissioning of equipment until everything is functional;

4. Free management of equipments' long distance shipping;

5. Free training of equipment maintenance and operating personally;

6. Free new production techniques and formulas;

7. Provide 1 year complete warrantee and life-time maintenance service;

8. Engineers available to service machinery overseas.

9. Provide technical exchanging.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23