Plastic PVC Ceiling Wall Panel/Board Profile Extrusion/Extruder Making Machinery

HUAIAN ZHONGYUAN FLUID TECHNOLOGY CO., LTD. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

PVC Ceiling Production Line Ceiling Machine PVC Ceiling Profile Production Line Inverter ABB PVC Profile PVC Extrusion Ceiling Machine Ceiling Production Line PVC Ceiling Extrusion Line PVC Ceiling Production Line Transport Package Wood Specification sgs Trademark middle tech Origin Zhangjiagang City HS Code 84778020 Production Capacity 300kg/HrProduct Description

Product DescriptionThis machine is mainly PVC ceiling profiles. This PVC profile production line adopts advanced design concept to ensure the efficient extrusion of PVC material, max can reach 250phr CaCo3 to help customer save cost.

Plastic PVC celing production line

Technical data

Model/data | Max width | Extruder model | Motor power | Max capacity |

| YF180 | 180mm | LSZ51/105 | 22kw | 120kg/h |

| YF240 | 300mm | LSZ65/132 | 37kw | 260kg/h |

| YF600 | 600mm | LSZ80/156 | 55kw | 400kg/h |

| YF800 | 800mm | LSZ92/188 | 90/100kw | 650kg/h |

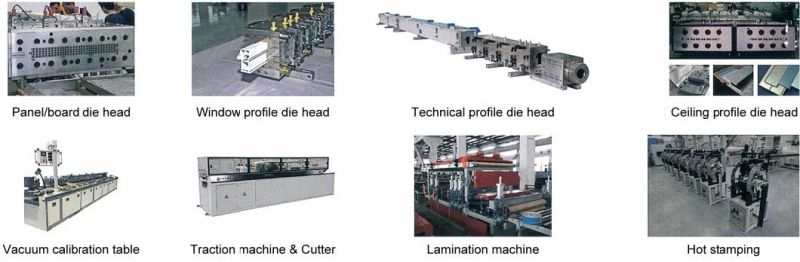

Components of PVC profile production line

a. Conical twin screw extruder:

Using the high efficient conical twin screws, specially designed for PVC power to ensure uniformed plasticization, high extrusion. Stable temperature controlling system can guarantee high quality pipe extrusion.

b. Extrusion Mould:

Spiral type die head will ensure high speed extrusion and avoid the thermal decomposition of amorphous plastics and get high quality PVC profiles. There is heating control system inside of the mould, high efficient, easy to extrude. Bronze calibrators can make the PVC profiles fast calibrated and cooled.

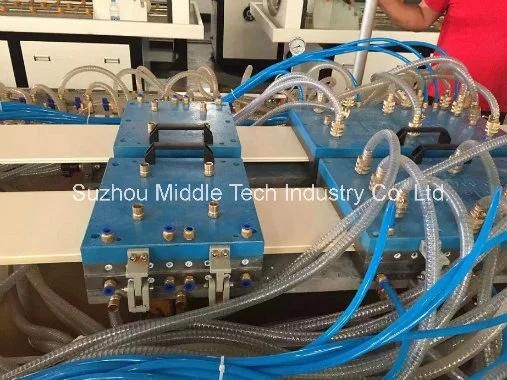

c. Calibration table:

Rapid vacuum calibrating system allows the hot extruded PVC profiles to be cooled in a very short time and obtain the final size. Automatic temperature control system, pressure regulator, and vacuum control valve greatly enhance the sizing and cooling performance as well as the production speed.

d. Haul off machine:

Adopts caterpillar type suitable for different sizes of pipes. Haul off caterpillar blocks are made of abrasion resistant rubber material, which can make a high and stable hauling speed.

e. Cutting machine:

Precision machine cutter is able to make flat, straight cuts at high speed. A powerful suction device gathers up waste scraps after cutting, thereby making it easier for users to clean the cutter.

6. Stacking:

Automatic stacking with fixed length

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23