Gl60 PP Ironwire Mask Nose Beam Coating Equipment

Kexin Electronics (HK) Industrial Limited / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

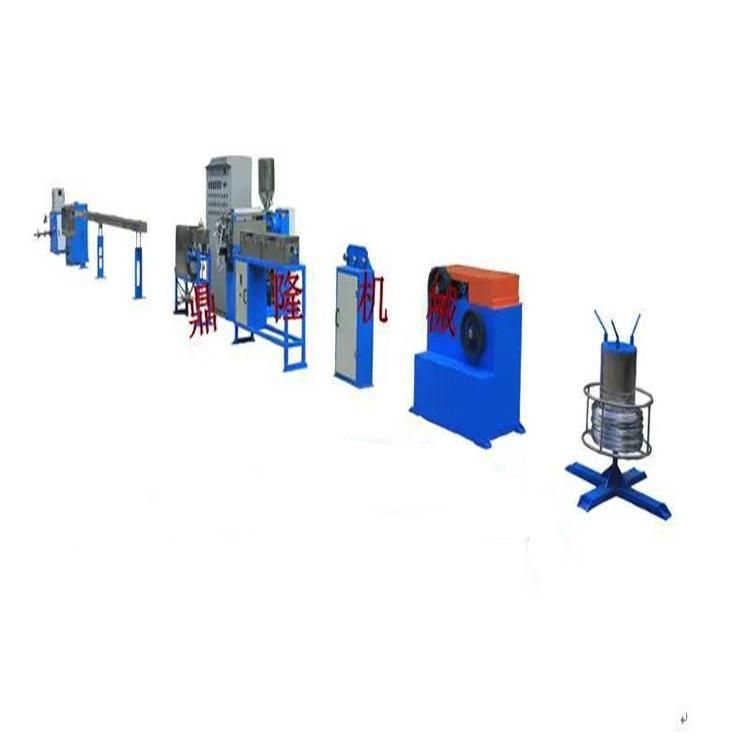

Model NO. DL60 Assembly Structure Integral Type Extruder Screw Single-Screw Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Don′t Exhaust Automation Automatic Computerized Computerized Finished Diameter 0.8-3.0mm Transport Package Export Wooden Case Trademark DL Origin China Production Capacity 100 Sets/YearProduct Description

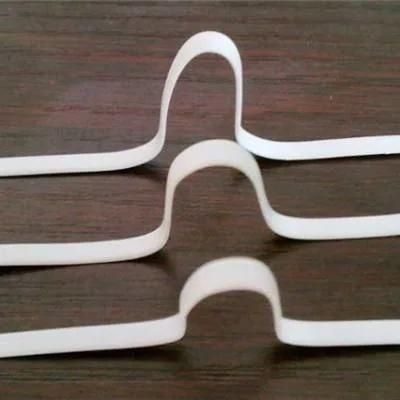

DL60 PP Ironwire/steel/Mask nose beam Coating EquipmentApplication:

Suitable for extrusion production of iron wire/steel wire/mask nose beam.

Technical Specifications

| Extruder type | DL35 | DL60 |

| Finished diameter | 0.6-1.8mm | 0.8-3.0mm |

| Line speed | 300m/min | 300m/min |

| Extusion output | 50kg/h | 50kg/h |

| Length diameter ratio of screw | 25:1 | 25:1 |

| Extruder power | 7.5kw | 15kw |

| Storage line length | 200m | 200m |

| Release form | Active wire laying/steel wire laying | Double-headed wire laying/steel wire laying |

Steel wire paying off frame

Double wheel tension frame

preheater

host

Movable sink

Caliper

Printer

Fixed sink

Extraction machine

Take-up machine

I Technical advantage (technology wins the market)

1, In 1997, we committed ourselves to the R & D and manufacturing of silica gel equipment and wire and cable equipment, with rich experience

2, Provide customers with solutions for various stages of silicone hose, wire, profile and cable production process, improve the equipment according to customers' products, and provide customers with the best equipment.

3, Provide customers with one-stop services such as plant planning, whole plant equipment investment planning, selection and allocation of developers and staff operation technology training.

4, New product development and certification technical support services. Our technicians are familiar with the production process of various silica gel products and national wire standards, the performance of various silica gel raw materials, and the development and certification of various electronic wires, silica gel wires, network wires, HDMI wires, power wires, Teflon wires, rubber wires and other products

5, With strong market share and good reputation, our company has gathered a large number of information about silica gel, cable materials and various conductors to provide good, most affordable and most convenient investment services.

II Team advantage (team building brand)

1, We have the most professional mechanical equipment design and R & D team in China to provide our customers with the most authoritative solutions to process difficulties and equipment shortcomings.

2, We have the most professional business team in the industry to provide our customers with the most considerate service, the most elaborate technical questions, the most comprehensive investment scheme, the most high-end silicone products and cable production technology.

3, We have the fastest service team in China, set up a 24-hour service hotline and stationed service teams all over the country to provide customers with timely and professional services.

4, We have the most stable production and manufacturing team in China to provide customers with punctual, high-quality and cost-effective mechanical equipment.

5, We have the largest industrial chain cooperative enterprise team in China, which can provide our customers with services other than equipment (rubber and conductor), and provide customers with free proofing and machine testing materials.

III Service advantage (service retention)

The company always attaches importance to customer requirements, has a strong sense of customer service, regularly provides customers with professional equipment maintenance services, has a perfect customer network, and can provide customers with fast localized personal services.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23