Polycarbonte PC PP Multiwall Hollow Roofing Sheet Extruder Machine

Xinzheng Lifa Abrasives & Abrasives Co. Ltd / 2022-07-04

=== Base Info ===

=== Description ===

Item

Description

Data

1

SJ120/35 Single screw extruder with stainless steel hopper

1 set

2

Screen exchanging unit for PC

1 set

3

Melting gear pump for PC

1 set

4

SJ45/30 Single screw extruder for UV layer

1 set

5

Melting gear pump for uv

1 set

6

T-type Die head (2100mm*4-6mm)

1 set

7

Vacuum calibrating board

1 set

8

cooling table

1 set

9

The first haul off machine with 12 rollers

1 set

10

edge cutting device

1 set

11

5000mm oven

1 set

12

Corona treating unit

1 set

13

up and down sides, double position film laminating device

1 set

14

The second haul off machine

1 set

15

Tranverse cutting machine (length-settled)

1 set

16

material conveyor+6000mm discharge table

1 set

17

eletrical cabinet

1 set

other accessory machine parts

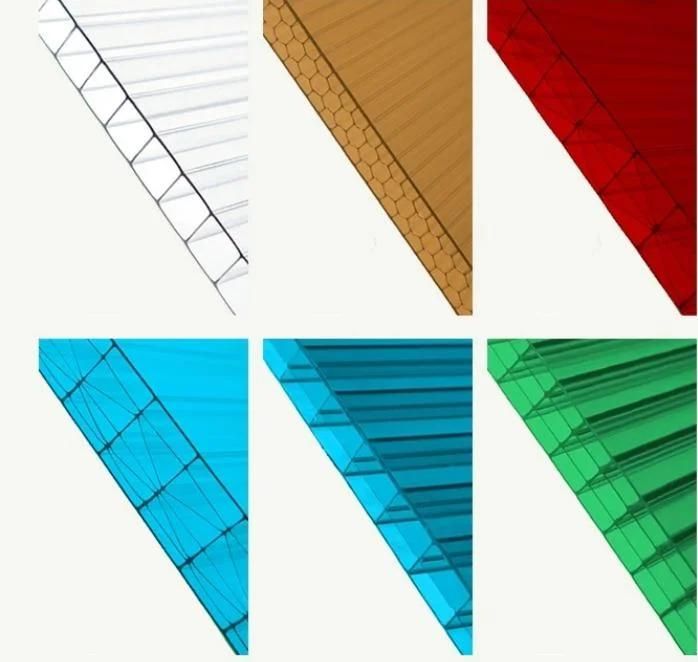

Double Wall/Triple Wall/Multiwall Polycarbonte PC hollow roofing Sheet Extrusion Line extruder machine

This extrusion line consists of single screw extruder, melt-pump, hydraulic filter exchanging unit, hollow

sheet die head, vacuum calibrating table, first haul off machine, oven, corona treating unit, cooling table, second haul off machine, trimming and length-settled cutting units and stacker etc.

Characteristics of vacuum calibrator:

1. High quality mould steel or high strength Al-Mg Alloy

2. Special harden treatment and non-sticky coating on the surface.

3. Independently controlled vacuumize device and temperature controlling system.

4. Consist of vacuum sealing edge device.

The technology of hollow sheet die with co-extrusion feed block to get UV+PC+UV, UV+PC hollow sheet can save 30% UV on the surface.

Hollow Sheets Specifications:

Sheet width: 600mm-700mm-1050mm- 1220mm-2100mm-2300mm,

Sheet thickness is 4mm-6mm-8mm-10mm-12mm.

Sheet walls: double walls , three walls, 4 walls and more etc.

Application:

1) Sunshades for stadium and bus shelters2) Lighting for corridors, passages and subway entries3) Bank ATMs4) Sound and heat insulation for construction such as: houses5) Canopies for agriculture greenhouse, zoos6) PC sheets mainly used for building and decorating materials, greenhouse material, telephone booth, insulation shield express ways & highways7) Office building, hotels, villas, stadium, schools, bus stop, terminals, hospitals, subway entry and exit doors, etc. MACHINE PICTURES:

MACHINE PICTURES: PACKAGING & SHIPPING:

PACKAGING & SHIPPING:Qingdao Leader Machinery Co.,ltd will help you calculate the detailed dimension and the number of Container. And we promises delivery the machine within duration. It is based on our experience of manufactruing machine and management. COMPANY CERTIFICATIONS:

COMPANY CERTIFICATIONS:

OVERSEA TRADE SHOWS:

OVERSEA TRADE SHOWS:

OTHER RECOMMONDED PLASTIC SHEET EXTRUSION LINES:

OTHER RECOMMONDED PLASTIC SHEET EXTRUSION LINES:1. PET sheet extrusion machine:

Processing material: PET virgin pellets(APET or PETG) plus flakes; Or 100% flakes

Thicknes range: 0.2-1.5mm

Net sheet width: 650mm-1500mm(or as per cusotmer's requirement)

Layer structure: Signle layer or multi-layer

Capacity: 350-650kg/h

Application: Thermoforming(cup, bowel, etc. ), stationery, printing sheet, packaging, etc.

2. PP/PS sheet extrusion machine:

Processing material: PP/PS virgin pellets plus recycle material;

Thickness range: 0.15-2mm

Net sheet width: 650mm-720mm-1000mm-1300mm-1500mm(or as per customer's requirement)

Layer structure: Single layer or multi-layer

Capacity: 200kg/h-1000kg/h

Application: Thermoforming(cup, bowel, etc. ), stationery, printing sheet, packaging, etc.

3. ABS/HIPS sheet extrusion machine:

Processong material: ABS/HIPS virgin pellets plus recycle material

Thickness range: 1-6mm

Net Sheet width: 1200mm-1600mm-2100mm(or as per customer's requirement)

Layer Structure: Single layer or multi-layer

Capacity: 600-800kg/h

Application: Vacuum forming, thermoforming, refrigerator inner layer, suitcase, etc.

4. ABS/PMMA sheet extrusion machine:

Processing material: ABS/PMMA virgin pellets plus recycle material

Thickness range: 1-8mm

Net sheet width: 1200mm-1600mm-2100mm(or as per customer's requirement)

Layer structure: Single layer or multi-layer

Capacity: 600-800kg/h

Application: Vacuum forming, bathtube, etc.

5. PE sheet extrusion machine:

Processing material: HDPE/LDPE/LLDPE virgin pellets plus recycle material

Thickness range: 1-2.5mm, 3-35mm

Net sheet width: 1200mm-1600mm-1800mm-2500mm-3000mm-40000mm-6000mm-8000mm

Layer structure: Single layer or multi-layer

Capacity: 500kg/h-1200kg/h

Application: Packaging, construction, water-proof, water-drainage, Geomembrane film, etc.

6. PC/GPPS/PMMA sheet extrusion machine:

Processing material: PC/GPPS/PMMA virgin pellets plus recycle material

Thickness range: 1-12mm

Net sheet witdh: 600mm-1220mm-2100mm(or as per customer's requirement)

Layer Structure: Single layer or multi-layer

Capacity: 400-600kg/h

Application: Ads., decoration, roofing, etc.

7. PC/PP/PE hollow profile sheet/ sunshine roofing panel machine:

Processing material: PC/PP/PE virgin material plus recycle material

Thickness range: 2mm-4mm-6mm-8mm-10mm-12mm

Net sheet width: 1220mm-2100mm

Layer structure: Single layer or multi-layer

Capacity: 400-600kg/h

Application: Ads. Decoration, roofing, packaging, printing, etc.

8. PVC sheet/edge banding sheet/marble sheet machine:

Processing material: PVC power plus other additive

Thickness range: 0.15-1mm; 1-3mm; 3-12mm

Net sheet width: 650mm-2000mm-3000mm( or as per customer's requirements)

Layer structure: Single layer or multi-layer

Capacity: 300kg/h-500kg/h

Application: Thermoforming, stationery, printing, payment card, SIM card, construction, etc.

9. EVA car interior decoration sheet extrusion line

Processing material: EVA and other additives

Thickness range: 1-8mm

Width range: 1000-1800mm

Layer strcuture: single layer

Capacity: 700-800kg/h

Application: automotive sealing strips, sound insulation cushion, sound absorption sheets,

automobile tail box, fenders, car interior and exterior decoration parts etc.

10. PVC+PMMA Glazed roofing tiles/corrugated sheet extrusion machine

Processing material: PVC, PMMA and other additives

Thickness range: 1-8mm

Width range: 720mm, 880mm, 1040mm

Layer structure: A/B, A/B/A, A/B/C

Capacity: 400kg/h

Application: garden-style factory, tourist scenic spots, pavillions, hotels, family building etc.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23