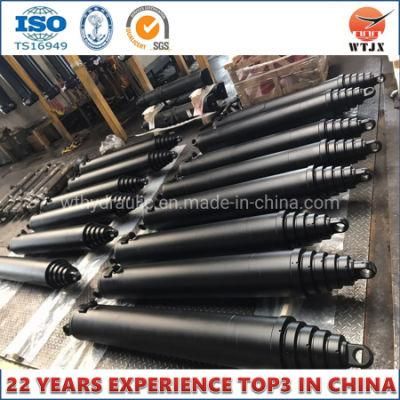

Single Acting Telescopic Hydraulic Cylinder

ZHEJIANG MAYEN PACKING CO., LTD. / 2022-06-27

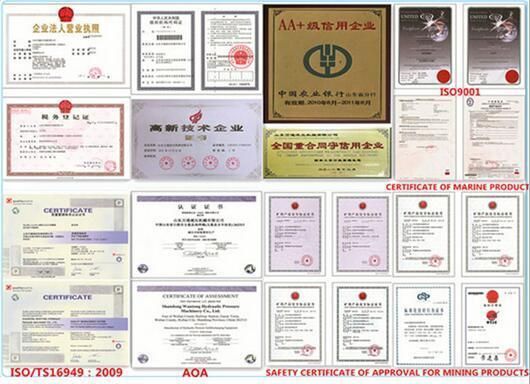

- Certification:CE, ISO9001

- Pressure:Medium Pressure

- Work Temperature:Normal Temperature

- Acting Way:Single Acting

- Material:Steel

- Working Temperature:-30---100degrees

=== Base Info ===

- Model NO.:WTPK 5TG F9*340

- Stork:2500-8630mm

- Place of Origin:Shandong, China

- Delivery Time:20 Days

- Certificates:ISO,Ts16949, ABS, API, SGS

- Color:as Customer′s Requirement

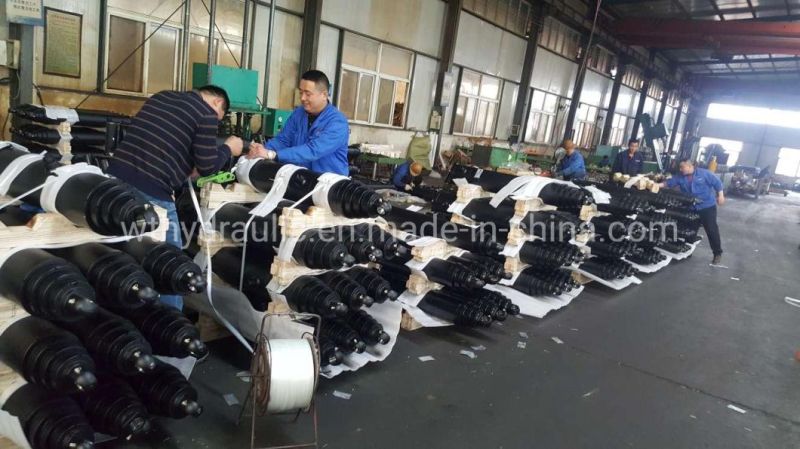

- Transport Package:Pallet

- Trademark:ODM , OEM , WTJX

- Origin:Shandong, China

- HS Code:841221

- Production Capacity:200, 000 Sets , Year

=== Description ===

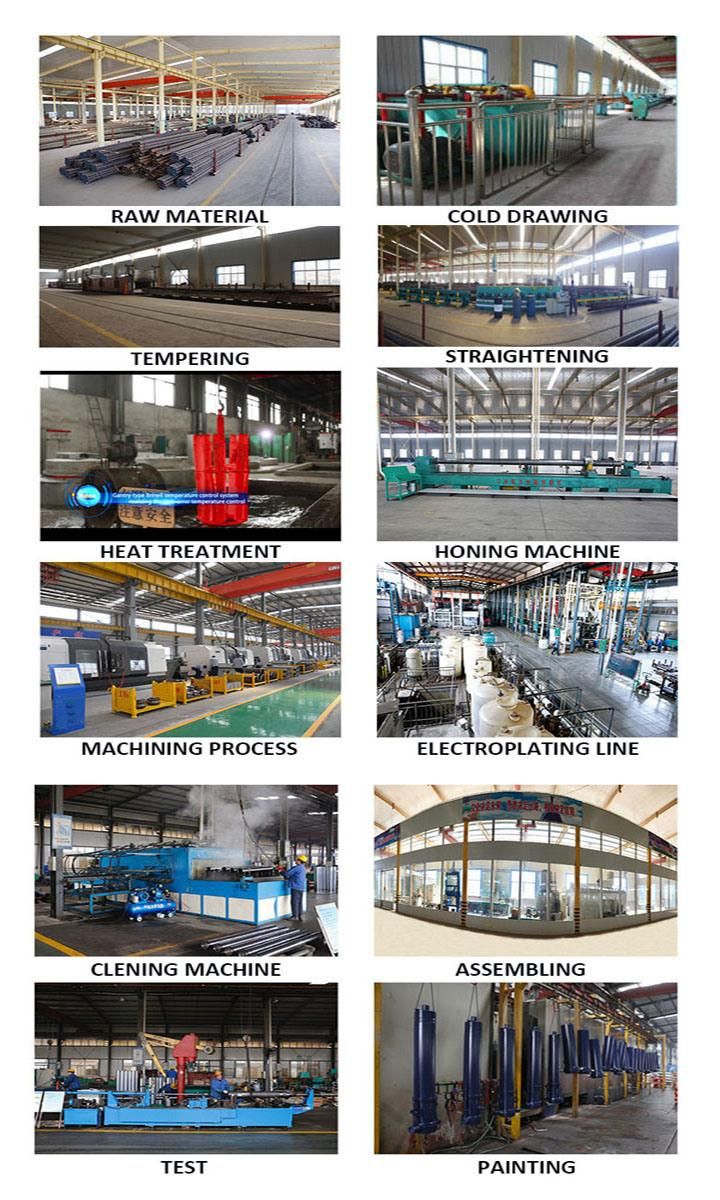

Production Process:

>Each processing under our control, each products, every step under strict quality control;

Exhibitions& Customers:

>We are the supplier of SINOTRUK, CIMC, JAC, SHACMAN, ZMJ and YANKUANG GROUP

manufacturing and refitting company use our telescopic cylinder as first choice.

>We attended each Bauma exhibition, the world trade fair for construction equipment, building material machines, mining machines and earn much more opportunity to extend our business to oversea market.

Quality Control:

1, The mechanical properties and chemical elements of the raw material will be inspected to check whether qualified after entering the warehouse.

2, Chemical composition inspection of raw materials, Test the chemical composition of metallic materials, such as C, Si, Mn, P, S, Cr, Ni and other elements.Mainly for raw materials incoming inspection, by testing whether the material qualified, receiving materials.

3, Metallographic analysis of metal materials is usually the raw materials, such as copper, iron, aluminum, magnesium, zinc, titanium, etc., for the processing of structural parts and finished product evaluation, through the metallographic analysis, You can find a variety of possible reasons for failure analysis in time, Prediction and analysis the characteristics of metallic materials and materials, Study material surface, and internal defects, and to improve and verify the process technology of the material;

4, Salt spray test is a major use of salt spray test equipment created by the artificial simulation of salt spray environmental conditions to assess the corrosion resistance of products or metal materials, environmental testing

5, Mechanical performance testing equipment can meet the requirements of mechanical testing, all the use of computer digital display, so the accuracy is more accurate so that the mechanical properties of each cylinder barrel has been greatly improved.

6, Every workpiece is machined according to the confirmed drawings and will be inspected casually by QC according to a certain proportion.The traceable record shall be clear and traceable.

7, The qualified parts are assembled into one cylinder and then the pressure test will be done.

Before and after assembly, the basic dimensions and workmanship will be inspected again.

8, An inspection report will come into being before delivery.

Certificated:

Package:

Guarantee and after sale service:

> Pre-sale service: Keep communicating with the truck manufacturers, including the selection of product model, the design of a hydraulic system, a test of performance and analysis of the accident. Once the problems occur, we will solve them immediately together with truck manufacturers.

>The sale service: Provide training and technical support for users.

> After-sale service: Solve the problem firstly, then analyze responsibility; Replace the system components

immediately if any need.

> 24 hours telephone service hotline.

FAQ

Our front end cylinder for tipper system have market share of top three in china.

Q1:Are you a manufacture or a trade company?

Answer:Manufacture, we are the leader manufacturer of hydraulic industry in China with 20 years' experience and technology accumulation.With strong technical team we could solve any annoyance of you.

Q2:Do you have quality control system?

Answer:Yes,We have Strict Quality Control System from Raw Material to the final finished products to customer .

Q3:Do your products come with a warranty?

Answer:Yes, Period of 14 months from the date of manufacture.The manufacture date is engraved on the label of every cylinder.

Q4:Hydraulic cylinder internal leakage?

Answer:3 main reasons causing internal leakage:Overload, polishing bad controlled, cheap seal kits.As is known to all, vehicles in China are often overloaded, our products all designed to bear the overload power.Advanced equipment could assure the polish processing.And we use the imported/TOP brand seals to meet customers' requirement.

Q5:Does your telescopic cylinder adopt chrome plating for every stage.

Chrome-plating technology is adopted for every stage of telescopic cylinders.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23