Wood and Plastic Composite PP PE PVC WPC Decking Co-Extruder Machine Production Line

Ningbo Easyget Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Characteristics

WPC

Wood

Moisture Resistance

Waterproof

Water absorptive

Rot Resistance

Antisepsis

Rot except special treating

Split Resistance

No Cracked

Cracked by weathering effect

Distortion Resistance

Almost no Contraction/expansion

Distorting effected by chang of moisture and temperature

UV Resistance

High Grade UV Resistance

Easily effected by UV

Fading Resistance

Almost no

Easy to fade

Outdoor adaptability

Great

Only few of treatedowood adaptive

No need painting

No need

Need paint periodically

Durable/longevity

> 10-15 years

< 3 years

Various Configuration

Extruded via various mould

simplex

Environment Effect

Recyclable 100%

Consume woods

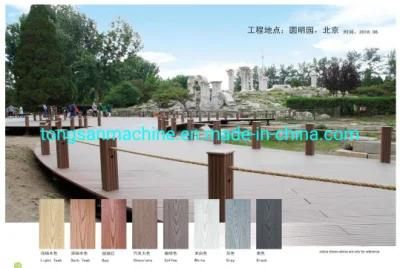

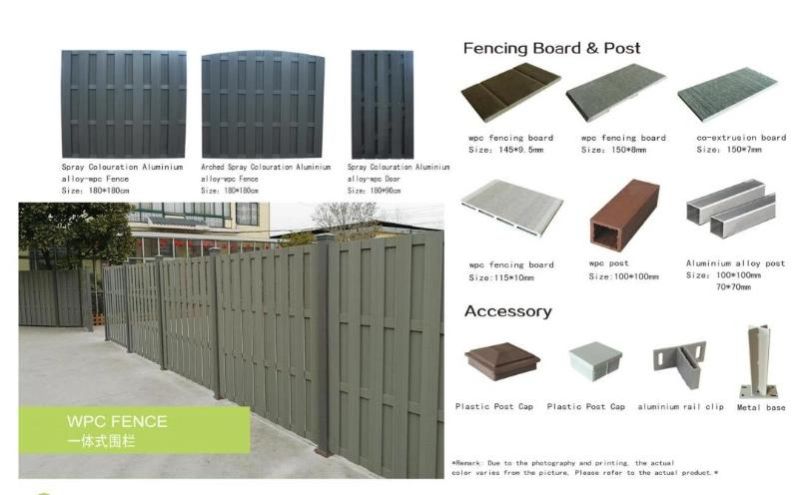

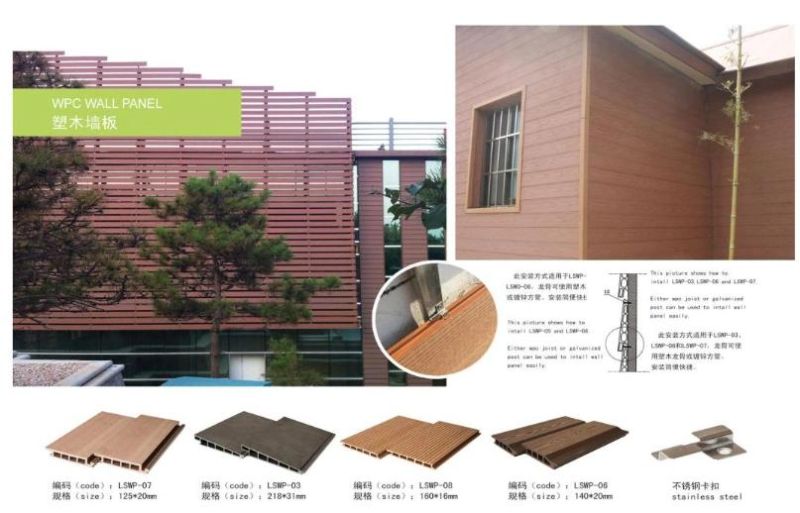

The PE WPC profile extrusion line is suitable for producing the hollow/solid PE WPC profiles. This profile has the advantage of fireproof, waterproof, moisture proof, moth proof, mildew proof and environment friendly. It is mainly used for extruding outdoor decorative WPC profiles, such as gardening landscapes, outdoor landscapes, pallets etc.

This extrusion line is for producing co-extrusion PP/PE WPC decking. The decking surface can be made into wood grain by co-extruder. Further more, the machine can be equipped with on-line embossing device the surface can be made into 3D wood grain. The WPC decking has a series of advantage including water-proof, insect prevention, ageing resistant, easy installation, environment friendly and good weathering resistance.

FAQ:

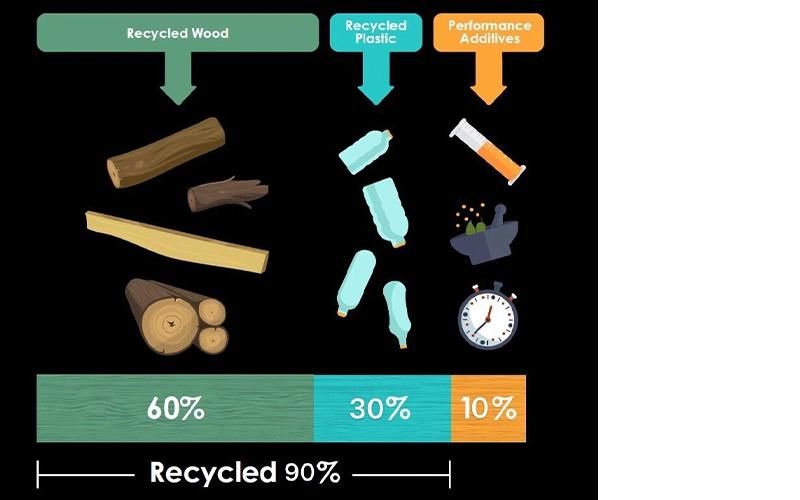

1. What's WPC?WPC is short for Wood Plastic Composite. The combination of the raw materials are mostly 30% recycled plastic (HDPE) and 60% wood powder, plus 10% additives such as anti-UV agent, lubricant, light stabilizer and etc.

2. What's the process to make WPC decking?

(a) Mix raw materials according to certain formula, then make them into pellets.

(b)By extrusion machine and mold, shape the products in customized profile and size.

(c)Do surface treatment such as sanding or embossing, then cut the WPC decking by requested length before package.

3. What are the benefits to use composite decking?

(a) Composite decking is waterproof, fire retardant, UV resistant, anti-slip, maintenance free and durable.

(b) Its profiles, lengths, colors, surface treatments are adjustable.

(c) It's easy to install and cost efficient.

(d) Since the raw materials are recycled, the product itself is eco-friendly.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23