Full Automatic Pure Steam Potato Blanching Peeling Machine

Yangzhou Compasslink International Trade Co., Ltd. / 2022-07-04

- After-sales Service:Overseas Service Center Available

- Warranty:1 Year

- Type:Washer

- Voltage:220V

- Power:1.1KW

- Customized:Customized

=== Base Info ===

- Model NO.:YWA1

- Transport Package:Standard Pack

- Specification:standard

- Trademark:Uwants

- Origin:Shanghai

- Production Capacity:7set,Year

=== Description ===

Basic Info.

Model NO. YWA1 Transport Package Standard Pack Specification standard Trademark Uwants Origin Shanghai Production Capacity 7set/YearProduct Description

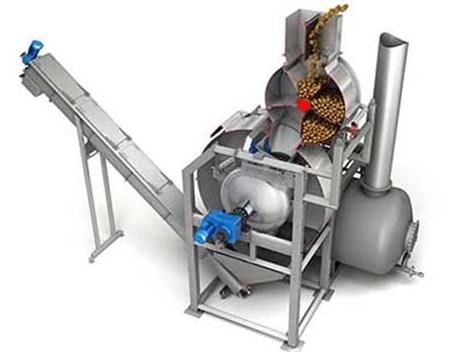

China Pure Steam Potato Blanching Peeling Machine BlancherSteam Peeler machine is the most ideal and economical steam peeling solution for seasonal processing enterprises and emerging markets. It is an advanced peeling equipment specially designed for seasonal processing enterprises of fruits and vegetables, such as almonds, apples, carrots, peppers, peaches, pears, sweet potatoes, taro, yams, papaya, mango and so on.

The peeler has confirmed the "Eco" label by exhibiting significant steam usage reductions and energy savings. The Eco technology changes the process from a fixed steam supply to a new controlled steam management system. The result is a substantial improvement in processing efficiency and significant savings in steam.

The Eco Peeler also includes a new peeling vessel design with patented design features and a unique parallel motion door. The high-pressure vessel contains an innovative product mixing design that enables rapid heat transfer of the steam to each product's surface.

These new design features allow for even better process control and shorter steam times. The addition of an entirely new process sequence combined with the above features results in lower peel loss.

Uwants offers a range of peeling solutions for French fries and food processing lines for various root vegetables.

Using Scope

The machine used for peeling potatoes, carrots, sweet potatoes, red beets, celeriac, swedes, pumpkins, peppers, chillies, ,root vegetable,taro and many others.

Main Advantage

1.Made of stainless steel 304.

2.Using multiple sets of high efficient screw knife peel the material.

3.Spiral knife with special heat treatment, sharp and durable.

4.Peel thickness control, high yield, high output, easy to clean.

5.Suitable for a variety of different materials, it can use single,also use group line.

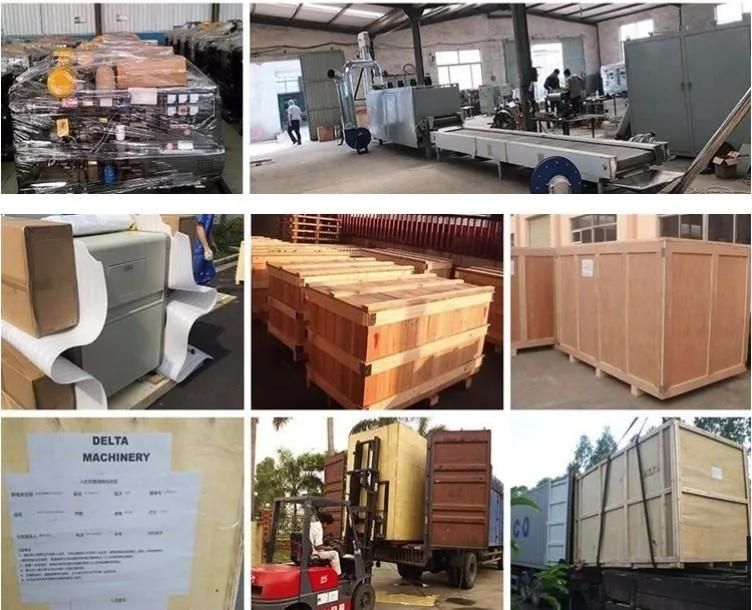

Packing & Logistic

We usually pack our products by standard export cartons as master carton. We always choose the best and safe packaging material to make sure your orders won't be damaged during delivery.

Shanghai UWANTS Machinery Manufacturing Co.,Ltd.is a professional manufacture of food processing machine and pressure vessel,inculding sterilization autoclave,jacketed pot,vacuum cooling machine,modified atmosphere packaging machine,vulcanization tank,autoclave,animal waste rendering plant,feather meal production line,fish meal production line,wood processing machine etc.

We have many years' experience in this industry. We can produce the machine according to your requirement and production.Please don't hesitate to contact me if you have any question or you are interested in any of our equipment, we will offer the best service to you within 24 hours.

Welcome to visit our company at any time and thanks for visiting our website!

Our Customer

Our Services

1. Pre-sales service:

*Sales person, project manager, technology engineer, accountant staff

*Professional responsing-team: would be very fast and exactly to send your offers

2. Online/sale service

*Super and solid quality

*Fast delivery

*Standard export package or as your demand

3. After-sales service

*Assistance to build factory

*Repairing and maintenance if any problem occur in warranty

*Installation and clerks training

*Spare and wearing parts for free or with big discount

*Any feedback of machines can be told us, and we will try our best to support

4. Other cooperation service

*Technology knowledge share

FAQ

1. What are the payment terms?T/T,L/C and trade assurance are acceptable,T/T will be more appreciated,30% deposit before production,70% balance before shipment.

2.What is the delivery time?

At least 2 month after the deposit for most machines

3.How to pack the machine?

Standard packaging

4.How to install after the machines arriving destination?

Our engineer will go to customers site if you need,but need to pay installation fee according to the contract.

5.What's the capacity you can do?

We always produce any capacity depend on customers' requirement.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23