Small Manual Hot Foil Stamping Machine in Stock

Shenzhen Tamprinter Printing Machinery Co., Ltd. / 2022-06-27

- Classification:Intermittent Stamping Machine

- Plate Type:Letterpress

- Color & Page:Single Color

- Suitable Material:Leather

- Automatic Grade:Semi-Automatic

- Application:Leather Heat Transfer, Business Card, Plastic Flexible Packaging, Arts and Crafts, Electronic, Labels and Tags, Cap, Toy, Apparel

=== Base Info ===

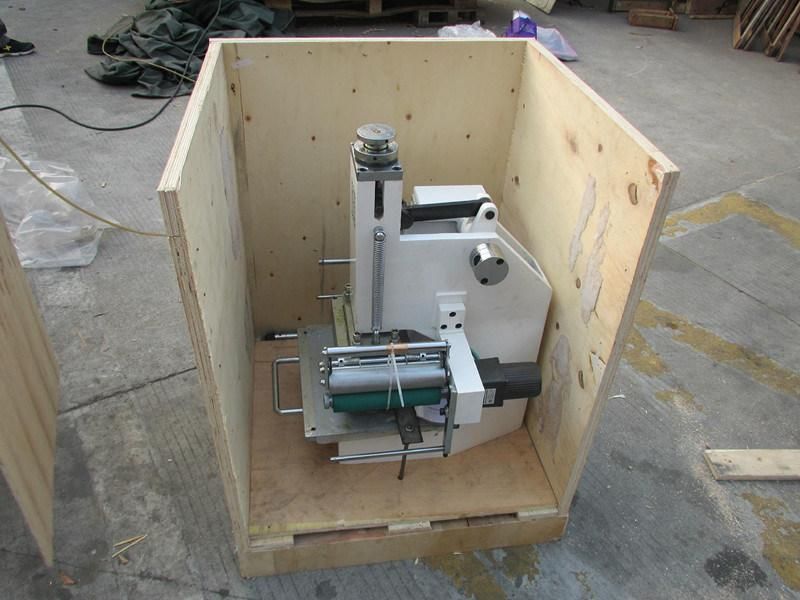

- Model NO.:TAM-358

- Usage:Leather Printer

- Hot Stamping Pressure Factor:Hot Stamping Temperature

- Decisive Factor:Temperature

- Impression Area:300X150mm (11.8" X 5.9")

- Power:220V

- Electrothermal Power:1000W

- Operation:Semiauto(60degree-400degree)

- Stamping Speed:700 PCS,H

- Print Head:300X150mm

- Worktable:350X320mm

- Pressure:2000 Kg

- Max. Product Thickness:190mm

- Gross Weight:180kg

- Transport Package:Plywood Case,Wooden Case,Carton,as Required

- Specification:CE; ISO9001-2000

- Trademark:Tamprinter

- Origin:China(Mainland)

- HS Code:8525801190

- Production Capacity:100 Sets,Month

=== Description ===

1

Model

TAM-358

2

Product shape

Plane

3

Impression area

300X150mm (11.8" X 5.9")

4

Power

220V

5

Electrothermal Power

1000W

6

Operation

semiauto(60degree-400degree)

7

Stamping speed

700 PCS/H

8

Print head

300X150mm

9

Worktable

350X320mm

10

Pressure

2000 kg

11

Max. product thickness

190mm

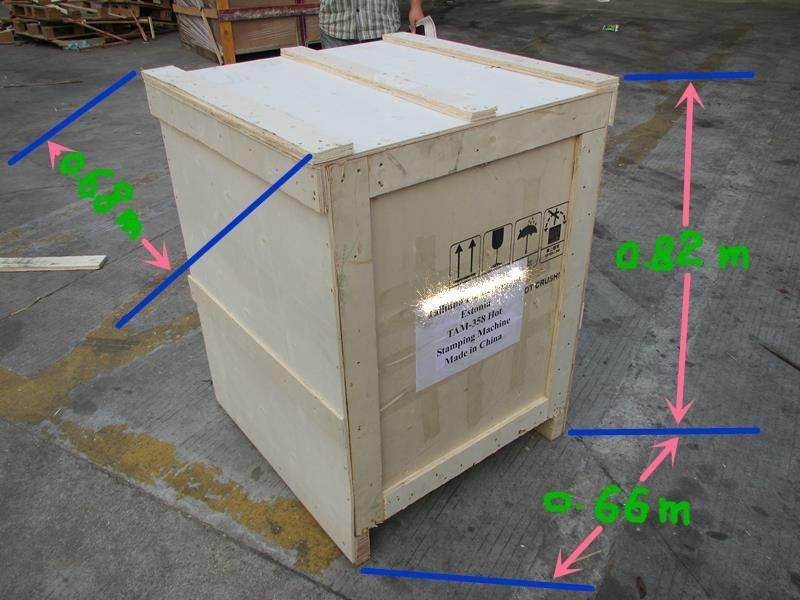

12

Machine Weight

146KG

13

Machine Outline Dimensions

620X580X770mm/68*66*82

14

Volume

0.9CBM

15

Lead Time

6 days after payment

16

SKU

50 SET

17

Packing

plywood case

18

Gross Weight

180KG

19

Payment Terms

TT/Western Union/LC

Characteristics

1. Semi-auto stamping, auto foil feeding, without compressed air, leads to easy operation.

2. Stamping temperature adjustable.

3. The height of the stamping head adjustable accordingly.

4. Automatic foil feeding and rolling with adjustable function.

5. The mechanism to transmit printing ribbon uses motor reduction gear with its length being properly controlled.

6. Horizontal sliding print bed - for accurate product placement.

7. Variable motorised auto foil feed - for minimal waste and effort.

8. Flat heating element - for efficient heat transfer. Micro-adjustable pressure - for the ultimate in convenience and versatility.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23