Nutritional Fortified Artificial Rice Making Production Processing Machine Equipment

Qingdao Baigu Plastic Products Co., Ltd. / 2022-07-05

- Processing Material:Grain Powder

- Application:Artificial , Nutritional Rice

- Customized:Customized

- Certification:CE, ISO9001

- Automatic Grade:Automatic

- Products Name:Artificial Rice Nutritional Rice Production Line

=== Base Info ===

- Model NO.:TSE65,70,75

- Function:Extrusion and Drying

- Material:Stainless Steel

- Screw Material:38CrMoAl

- Barrel:45#Steel

- Raw Material:Rice Powder, Corn Powder,etc

- Inverter:Delta

- Operators:1-2 Workers

- Service:Engineers Available to Serve Overseas

- Transport Package:Wood

- Specification:18*2*3m

- Trademark:Shengrun

- Origin:China

- HS Code:8438800000

- Production Capacity:30 Sets,Month

=== Description ===

Basic Info.

Model NO. TSE65/70/75 Function Extrusion and Drying Material Stainless Steel Screw Material 38CrMoAl Barrel 45#Steel Raw Material Rice Powder, Corn Powder,etc Inverter Delta Operators 1-2 Workers Service Engineers Available to Serve Overseas Transport Package Wood Specification 18*2*3m Trademark Shengrun Origin China HS Code 8438800000 Production Capacity 30 Sets/MonthProduct Description

Nutritional Fortified Artificial Rice Making Production Processing Machine Equipment

Artificial rice Nutritional Rice Production Line

Artificial rice production line is developed to meet the demands of food nutrition. The raw materials for artificial rice extrusion line can be rice, black rice, buckwheat and other grains.You can also add additional nutritious components, such as vitamins, minerals etc.

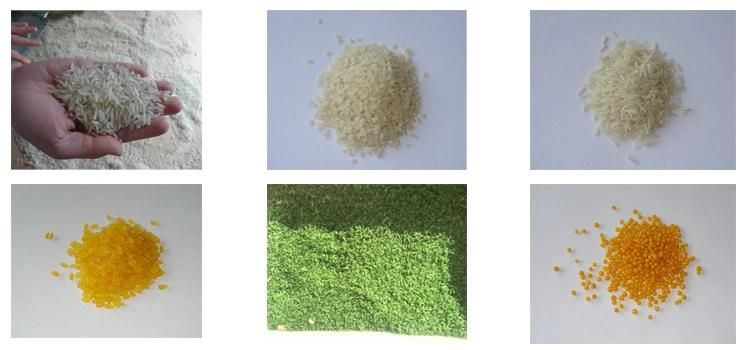

Raw materials

Rice powder, corn powder, wheat flour powder ,black rice, millet etc

Voltage and frequency

Three phases: 380V/50Hz, Single phase: 220V/50Hz (China standard)

We can make it according to customers' Local voltage according to different countries (440v/ 415v /480v).

Production capacity

100-150kg/h, 200-250kg/h , 300-400kg/h

Technical parameters

| Model | TSE70-R | EXT100 |

| Installed power | 105kw | 100kw |

| Power consumption | 75kw | 70kw |

| Production capacity | 200-250kg/h | 100-150kg/h |

| Dimension | 22*1.5*2.2m | 21*1.3*2.2m |

Flow chart

Mixer-Screw conveyor- extruder-vibrating feeder-air conveyor- roasting oven- cooler

Products smaples

Machine details

Packaging and shipping

The machines will be wrapped by plastic bags firstly and then packed in wooden case.

Our shipping agents and delivering equipments will be ready in time to ensure timely delivery and safety of the goods.

FAQ

Q1. Are you a manufaturer or a trading company?

Answer: We are a professional manufaturer with trading department.

Q2. Could we visit your company to check the machine?

Answer: Of course! Highly appreciated your visit to our company.

Q3.Could you provide customized machine?

Answer: We can manufacture the machine as your request.

Q4.What's your payment system?

Answer: Usually T/T: 30% deposit,70% payment before delivery

LC is also acceptable.

Q5: Do you have your own shipping agents?

Answer: Yes,We have long-term cooperation shipping agents. We can ensure the safety delivery ;

Q6:How about the installation ?

Answer: We can dispatch our technician to guide you the installation and teach you how to operate the machine.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23