Pharmaceutical Extracting and Separating Machine for Flavonoid Coptisine Cannabis

Zibo Tianheng New Nanomaterials Technology Co., Ltd / 2022-07-05

- Condition:New

- Customized:Customized

- Voltage:380V

- Composition:Extractor and Concentrator

- Processing Material:Natural Ingredients

- Process:Thermal Processing

=== Base Info ===

- Model NO.:DTWZ-D

- Operation Pressure:Vacuum or Normal

- Production Line:From Distillation to Drying Machine

- Finished Product:Paste, Liquid, Ointment, Solid, Powder

- Heating Source:Steam or Electrical

- Solvent Recycling:Yes

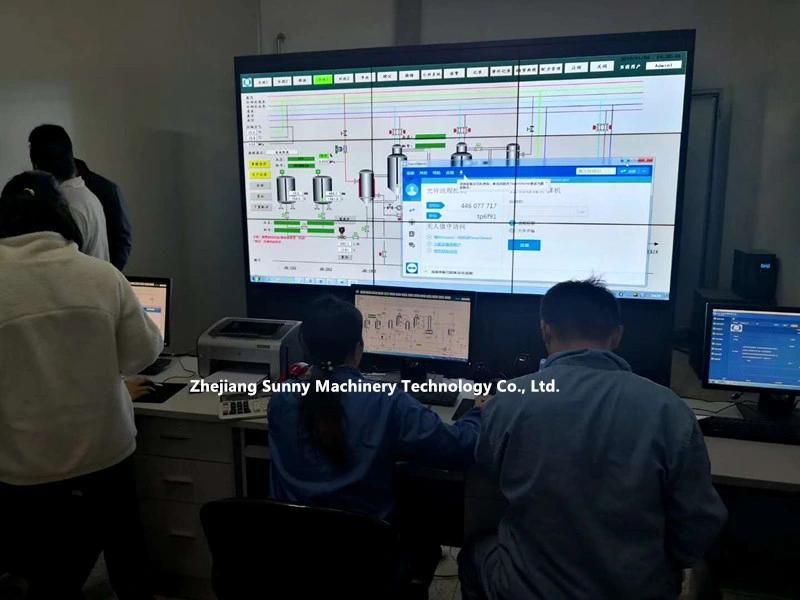

- Automatic Operation:Completed with Siemens PLC Module

- Transport Package:Sea Worthy Wooden Packing

- Specification:as customized

- Trademark:Zhejiang Sunny Machinery,OEM

- Origin:Wenzhou China

- HS Code:8419899090

- Production Capacity:20sets,Year

=== Description ===

Basic Info.

Model NO. DTWZ-D Operation Pressure Vacuum or Normal Production Line From Distillation to Drying Machine Finished Product Paste, Liquid, Ointment, Solid, Powder Heating Source Steam or Electrical Solvent Recycling Yes Automatic Operation Completed with Siemens PLC Module Transport Package Sea Worthy Wooden Packing Specification as customized Trademark Zhejiang Sunny Machinery/OEM Origin Wenzhou China HS Code 8419899090 Production Capacity 20sets/YearProduct Description

Complete Production Line for Automatic Herbal Extraction and Concentration Application .

Sunny Machinery Technology is committed To Be A Brand Company Servicing and Supplying Complete Equipment for Big Healthy Industries in Pharmaceutical, Food and Beverage, Cosmetic, Chemical Sectors

Control Function of Major Process Unit

1, Solvent dispensing: with on-line detection of liquid level, temperature, PH value, purification water level, etc. The system controls purification water control valve, solvent discharging pump and cleaning liquid discharge pump.

2, Extraction unit: on-line detection of liquid level, temperature, pressure, heated steam pressure, flow rate of solvent. The system automatically adjust heated steam according to set temperature rise time and holding temperature. The solvent inlet control valve and extract discharge pump and valve can also be automatically controlled on line.

3, Double or Single-effect concentration unit: on-line detection of single-effect and double-effect liquid temperature, gas phase temperature, liquid level, vacuum degree, density, heated steam pressure, feeding volume. The system will automatically adjust heating steam according to set temperature and vacuum degree, as well as feeding flow rate and concentrated discharging.

4, Alcohol deposition unit: on line detection of deposition tank temperature, alcohol flow rate, the system will automatically adjust the jacket heating and cooling water flow rate, motor rotating speed, alcohol loading speed and flow rate according set configuration.

5, Column chromatography unit: on line detection of purificated water flow rate, acid or alkali rate, alcohol flow rate, material flow rate, etc. The system will automatically adjust these process parameters and accumulates. Meanwhile automatically control of chromatographic column liquid level.

Taper Type Extracting Tank ( Z shape)

It takes smaller space on installation with faster heating speed.

Mushroom Type Extracting Tank ( M shape )

The appearance is big at the top and small at the bottom, the shape of mushroom provides more buffering space with less foam.

Straight Cylindrical Extracting Tank (T shape)

With long and thin appearance, it takes larger space for installation, bottom heating could be increased for better heat and medium transfer and easy residue discharge.

Basket Lifting Type Pressed Extracting Tank (Y shape)

With upper open cover structure and inner heating direct injection unit, it is suitable for animal bones extraction with high efficiency and high pressure resistance.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23