Used Plastic Grinder Pet Bottle Shredder Machine Plastic Recycling Grinder

XIAMEN ROCA IMP.& EXP. CO., LTD. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Name Used Plastic Grinder Pet Bottle Shredder Machine P Plastic Shredder Single Shaft Shredder Shredder Blades High Quality Material, Precise Processing Way Knife Roller Solid Knife Roller Roller Rotor as Designed Based The Capacity Motor Siemens Serivce Technical Support, Installation Price Competitive Factory Price Quality Control 100% Test Before Delivery Service Technology Support Delivery Time 30days Final Size Small Plastic Size as Request Input Material Various Plastic Material Structure Tangential Infeed Advantage Unique Design Knife, Steady Production Transport Package Contanier Specification as designed Trademark HVST Origin Zhengzhou, China HS Code 84778000 Production Capacity 100set/MonthProduct Description

used plastic grinder pet bottle shredder machine plastic recycling grinderIntrodustion of single shaft shredder:Single Shaft Shredders is designed to process waste plastic materials, these shredders are ideal for especially hard and voluminous products. The large shredding chamber and loading hopper capacity, combined with the PLC controlled horizontal RAM pusher ensures optimum feeding of material to the rotor therefore achieving the most efficient performance. Throughputs typically range between1,500kg/hr and over12,000kg/hr,etc

General Description

Single shaft shredders with a tangential infeed to eliminate the need for a hydraulic feeding system. The Space saving and maneuverable design combined with the plug and play controls make this machine very flexible Utilizing the proven knife holder and knife design. The user friendly design makes cleaning and maintenance work a breeze. The low speed of 60 rpm combined with the compact design of the single shaft shredders makes it possible to shred lumps at a relatively low noise level. The machines can be fed manually or by conveyor, material discharge can be done via conveyor or into a drop box.

Applications

The single shaft shredders have been designed for in house recycling of small lumps and purges from injection and blow molding processes. The typical input materials are small and medium sized cakes such as head waste. The material can be shred to reduce the volume or processed further in a granulator to be re introduced into the production process immediately. The machine also can be used to destroy sensitive products or to recycle small batches of low volume products to avoid contamination of the main product line.

Picture of single shaft shredder for your reference:

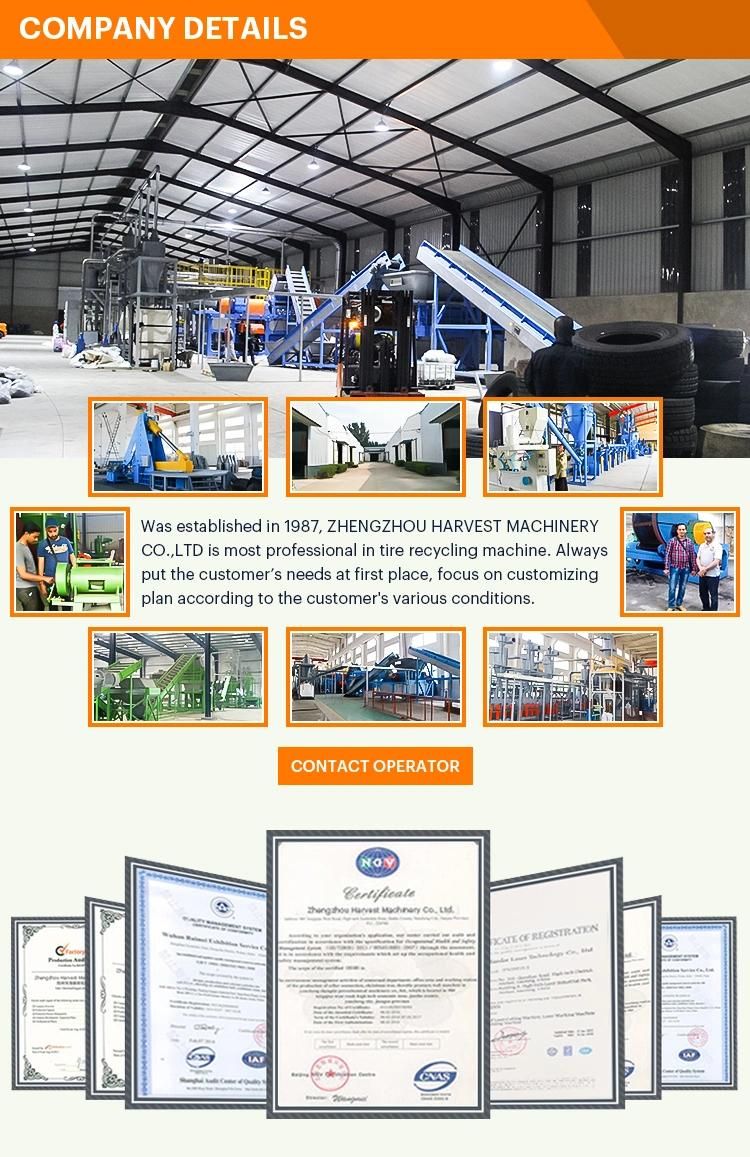

Company infomation:

We has been focused on designing and manufacturing equipment for the recycling industry more than 20 years, we mainly focued on providing our customer cost-effective waste recycling system applied in all kinds of waste recycling like tire/plastic/wood/metal/car/pcb board recycling,etc.

As a leader in providing cost effective turnkey tire recycling systems. Our main focus is to provide custom designed tire recycling systems that deliver optimum production for a variety of applications such as TDF (Tire Derived Fuel), rubber mulch, and rubber granule(crumb), rubber powder. We have manufactured and installed recycling systems in countries all over the world.

Service:

Before-sales service:

1. Technical proposal

2. Answer questions within 8 hours

3. Tested machine

After-sales service:

1. Install and debug machine, train workers

2. Free spare parts within gurantee period

3. Long time technical support when production process

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23