Cooling Drum with Automatic Feeding Via Belts for Toffee Chewy Candy Machine

Guangzhou Sengmi Packaging Co., Ltd. / 2022-07-05

- Certification:CE, MET, CSA, UL, SA8000, ISO9001

- Process:Frozen and Chilled

- Automatic Grade:Automatic

- Application:Ice Cream, Candy, Chocolate, Popcorn, Chips, Biscuit, Donut

- Customized:Customized

- Voltage:380V,415V

=== Base Info ===

- Model NO.:DA900

- Capacity:500kg,H

- Material:304 Stainless Steel

- Weight:15000kg

- Steam Pressure:0.8MPa

- Air Pressure:0.4MPa

- Keyword:Toffee Forming Machine

- Motor:Servo Motor

- Temperature Controller:Omron

- Electric Parts:Schneider

- Cooling Type:Air Cooling

- Tunnel:3 Layers

- Weigh:Automatic

- Belt:PU,PE

- Hopper:Telflon

- Transport Package:Plastic Film with Woodern Box

- Specification:304stainless steel

- Trademark:DAM

- Origin:China

- HS Code:84382000

- Production Capacity:50set,Year

=== Description ===

Basic Info.

Model NO. DA900 Capacity 500kg/H Material 304 Stainless Steel Weight 15000kg Steam Pressure 0.8MPa Air Pressure 0.4MPa Keyword Toffee Forming Machine Motor Servo Motor Temperature Controller Omron Electric Parts Schneider Cooling Type Air Cooling Tunnel 3 Layers Weigh Automatic Belt PU/PE Hopper Telflon Transport Package Plastic Film with Woodern Box Specification 304stainless steel Trademark DAM Origin China HS Code 84382000 Production Capacity 50set/YearProduct Description

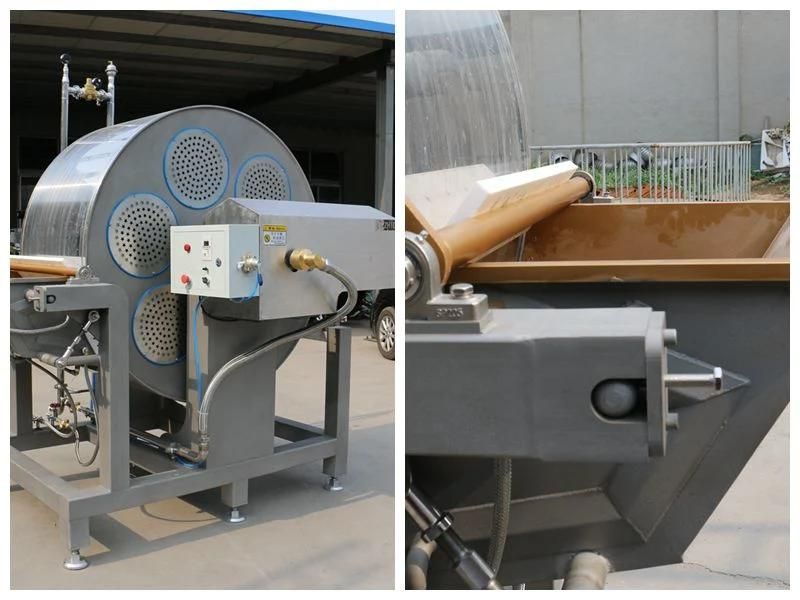

Name: Continuous Pulling Machine .

Product Description: This machine can be continous pulling the material which conveyed from the Cooling Drum. And It can auomatic discharge , and feeding to the extrusion and forming line.

Continuous Pulling Machine Features

- It can be controlled by Frequency changer on Touch Screen (Siemens)

- With safety cover, when it is opened , can be automatic stopped.

- Pulling arm are made by Polyethylene tetrafluoro, candy material will not stick on the arm,make sure the material can be continous conveyed.

Features 1.Chiller water inside for cooling down the candy material covered on the Drum 2.The Drum is connected with individual motor3.Hopper is made with telflon covered, in case the candy stick on the surface.

Features 1.Chiller water inside for cooling down the candy material covered on the Drum 2.The Drum is connected with individual motor3.Hopper is made with telflon covered, in case the candy stick on the surface.Manufactured Goods

Packing &Shipping

Packing &Shipping  1.Factory Near to Qingdao port , it is convient for transportation .

1.Factory Near to Qingdao port , it is convient for transportation .2.Plastic film covered with the equipment, and packaged with woodern box.

3. when loading to the container, it will be reinforece by metal wire.

Factory&Exhibition

Factory Patent

FAQ

1.What is your company advantage ?

We have own factory ,designed and manufacture by ourself. Near the Qingdao port, it is very convinent for exporting . Cheap than European machine, short delivery time than Germany machine.

2.What is the payment terms?

T/T or L/C , 30% advance deposit ,70% before loading .

3.Where is the factroy location?

Dongying City ,Shandong Province, China, North of the China.4.Could you please send me your best price?Before quoting, please kindly consult us and provide a.The type of confectionery you will produce.b.The size of your product, your expected capacity for the line or machine

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23