Fried Baked Cheetos Kurkure Nik Naks Food Extrution Machine

AIRMAX AL CO., LIMITED / 2022-07-05

- Certification:CE, UL, ISO9001

- Power Source:Electric

- Process:Thermal Processing

- Automatic Grade:Automatic

- Application:Ice Cream, Candy, Chocolate, Popcorn, Chips, Biscuit, Donut

- Customized:Customized

=== Base Info ===

- Model NO.:KS Series

- Transport Package:Wooden Case

- Trademark:KS

- Origin:Shandong, China

- HS Code:8438800000

- Production Capacity:30 Set,Month

=== Description ===

Basic Info.

Model NO. KS Series Transport Package Wooden Case Trademark KS Origin Shandong, China HS Code 8438800000 Production Capacity 30 Set/MonthProduct Description

Automatic Kurkure Production Line Equipment/Cheetos Making MachineFeatures :

Food Extruder; Twin Screw Extruder

1. Food Grade Stainless Steel

2. LG, FUJI Electric Parts

4. Food Processing Line machine

5. Puffed Snacks food machine

6. Kurkure/Cheetos/Nik Naks production equipment

7. 1 Year Warranty

8. Raw materials: corn grits

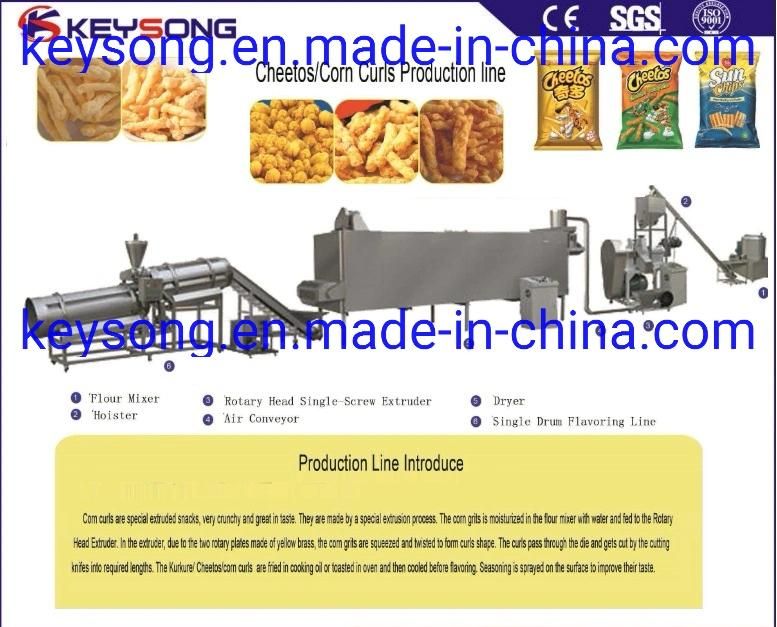

Cheetos/Corn Curls Production Line:

1. Detail Description

Kurkure are extruded snacks, very crunchy and great in taste. Kurkure are made by extrusion process. The Kurkure corn meal is moisturized in the flour mixer with water and fed to the Rotary die Extruder. In the extruder, due to excess heat and pressure from the screws the meal gets heated and the moisture content gets reduced. The meal passes through the die and gets cut by the cutting knifes into required lengths. The Kurkure are fried in cooking oil and then cooled before flavoring. Seasoning is sprayed on the Kurkure to improve their taste.

2. Processing Line

Flour Mixer → Screw Conveyer → Rotary Head Extruder → Hoister → Separate Drum → Vibrate Feeder → Continuous Fryer → Vibrate de-oil Machine → Flavoring/Seasoning Machine

This processing line from feeding, extruding, shaping ,cutting , oil spraying to finished products are done once time automatically. Visible auto-temperature controlling system, make the temperature-controlling to be more direct-viewing, parameter to be more precise.

3. Specifications:

The screws are made by ally steel and special craft, the screw life is longer, uses building block system structure, may combine willfully.

The forced lubrication system can guarantee equipment transmission longer life.

1. Raw materials: Corn Grits

2. Products: Kurkure/Cheetos/Niknak with different taste

3. Capacity: 120-140 KG/H, 180-240 KG/H

4. Flow Chart: Mixing-Extrusion-Separating-Frying/Baking- Flavoring

5. Voltage: Three phases: 380V/50HZ, Single phase: 220V/50HZ, we can make it according to customers' local voltage of different countries.

6. Machines Materials: All the machines are made by food grade stainless steel.

This is the core part of the whole baked kurkure making machine. Its main function is to extrude, rub and turn the mixer of raw material and water into the basic shapes.

This part can fry the kurkure and make the products crispy. The machine can control the temperature, easy to operate and clean.

The roller is full set stainless steel. With the rolling of the drum, the flavor and oil can be mixed with Kurkure evenly.

4. Technical parameters

| Model | KS-100 | KS-120 |

| Installed Power | 70KW | 100KW |

| Power Consumption | 50KW | 70KW |

| Max. Output | 80-100kg/h | 100-150kg/h |

| Dimension | 29000*2000*2200mm | 27000*2000*2200mm |

5. Products Pictures:

6. Packing & Shipping:

Each machine is carefully packed. It is packed with cling films first and then film bags. At last, it is packed with wooden case which is reinforced with the iron bar on the top and bottom. With this kind machine, all our laser machine can protect well during long trip by sea or by train.

7. Our factory:

8. Our customers:

9. FAQ

1. Q: Are you a trading company or a manufacturer?

A: We are the manufacturer, which has almost 10 years of experience in this industry.

2. Q: How can I get to your company?

A: That's great you can visit our factory, welcome! You can take a flight to Jinan International Airport, which is 30 minutes' drive from our factory. And we will pick you up.

3. Q: How long is your guarantee?

A: One year.

After this period we will definitely support you when needed.

4. Q: Will you send engineers to install the plant?

A: yes, but at an extra cost payable by the customer. Or you can get local contractors to do the commissioning and we send one supervising engineer.

Contact:

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23