Hot Sell Stainless Steel IQF Tunnel Freezer

Jiangyin Yiran International Trading Co., Ltd. / 2022-07-05

- Processing Material:Animal Raw Materials, Forest Products, Special Agricultural Products, Garden Products, Agronomic Products, Natural Ingredients, Sea Food,Fruits,Vegetables

- Application:Frozen Food

- Customized:Customized

- Certification:CE, ISO9001

- Power Source:Electric

- Automatic Grade:Automatic

=== Base Info ===

- Model NO.:SDJ

- Turn-Key Project:Automation

- Delivery:60days

- Transport Package:Wooden Packing

- Specification:as customer capacity

- Trademark:GENYOND

- Origin:China

- HS Code:84386000

- Production Capacity:800 Sets Per Year

=== Description ===

Basic Info.

Model NO. SDJ Turn-Key Project Automation Delivery 60days Transport Package Wooden Packing Specification as customer capacity Trademark GENYOND Origin China HS Code 84386000 Production Capacity 800 Sets Per YearProduct Description

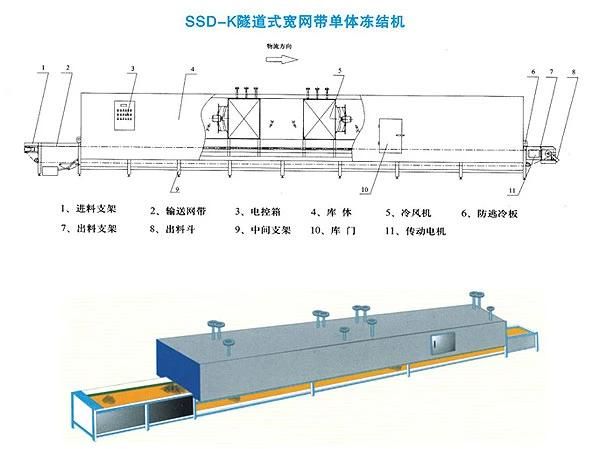

The structure of tunnel freezer is simple and reliable. It is a line from products inlet to products outlet. Because of the

limitation of its structure, the length of tunnel freezer is much longer than spiral freezer with the same output capacity.

Its advantages (comparing with spiral freezer with same output capacity):

(1) Simple structure;

(2) The inlet device and outlet device are in the same height, while single drum spiral freezer must be one is lower

and the other is higher;

(3) Lower price;

Its applications:

Tunnel freezers are mostly used for flour food freezing, fruits & vegetables freezing, meat freezing, seafood freezing

and prepared food freezing.

Its structure:

(1) Stainless steel conveyor belt;

(2) Sandwich PUF panels 150mm thick, laminated by stainless steel sheet both sides; floor panels are equipped;

(3) Door is equipped with frame heating device;

(4) Aluminum evaporators, different fin pitches;

(5) Axial fans: stainless steel air box, aluminum blades;

(6) Whole welded stainless steel water discharging plate is installed on top of floor panels. It will bring defrosting

water out of cabinet through many stainless steel draining pipes;

(7) The inlet device, outlet device and all structure parts are made of stainless steel;

(8) Control panel is made of stainless steel;

(9) Schneider or Siemens electric components;

(10)SEW speed reducer.

Technical Parameters:

| Model: TF Series | Output | Installed Power | Refrigeration Consumption | Dimension L*W*H | Belt Width |

| TF100 | 100kg/h | 2.25kw | 15kw | 7.0*1.5*2.1m | 1000mm |

| TF150 | 150kg/h | 2.95kw | 21.5kw | 8.0*1.8*2.2m | 1300mm |

| TF300 | 300kg/h | 6.5kw | 43.5kw | 11.2*2.3*2.3m | 1800mm |

| TF500 | 500kg/h | 10.3kw | 75kw | 13.5*3.0*2.5m | 2500mm |

| TF1000 | 1000kg/h | 19.8kw | 142kw | 22.9*3.0*2.5m | 2500mm |

| TF1500 | 1500kg/h | 28.6kw | 225kw | 26.4*3.5*2.5m | 3000mm |

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23