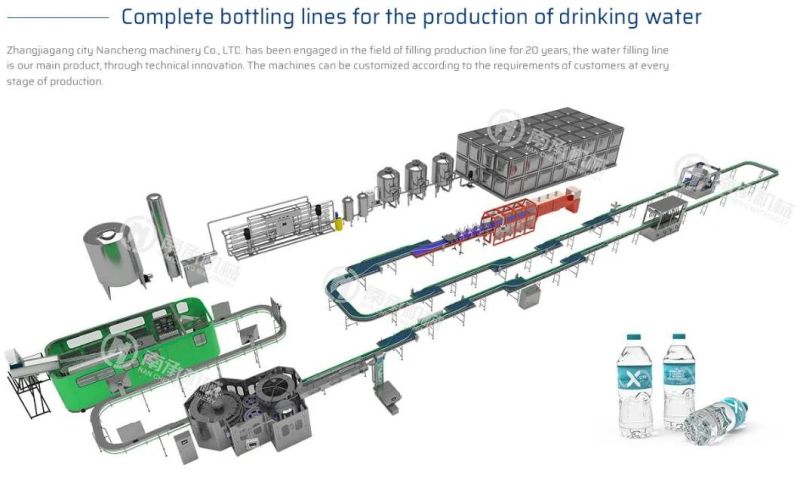

Latest Automatic 3 in 1 Filling Sealing Machine for Pure Water and Mineral Water

NINGBO HOBA INTERNATIONAL TRADING CO., LTD. / 2022-07-05

- Condition:New

- Customized:Customized

- Voltage:220V,380V

- Composition:Filling Machine

- Processing Material:Stainless Steel

- Process:Finish Machining

=== Base Info ===

- Model NO.:NC

- Material:SUS304

- Capacity:6000-8000bph

- Power:5kw

- Control:PLC+Touch Screen

- Driven Type:Electric

- Weight:2500kg

- Filling Principle:Atmospheric Pressure

- Certification:Ce,SGS,TUV

- Transport Package:Exported Wooden Case

- Specification:2500x1750x2200mm

- Trademark:NC Machinery

- Origin:Zhangjiagang

- HS Code:8422303090

- Production Capacity:10 Sets, Month

=== Description ===

Technical parameter: Water bottling machine

Main components:

| NO | Name | Model | Unit | Qty | Manufacturer | Remark |

| 1 | Main motor | Y90L-4 1.5KW | Set | 1 | Suzhou | Frame |

| 2 | Sort caps motor | YCJ90W-4 0.06kw | Set | 1 | Yongjia | Frame |

| 3 | Washing pump | 0.37kw | Set | 1 | Linxiao | Frame |

| 4 | Water pump | BJZ037S 0.37kw | Set | 1 | NanFang | Frame |

| 5 | Conveyor motor | UDL 0.37KW | Set | 1 | Taizhou | Frame |

| 6 | Air conveyor motor | Y802-2 0.75KW | Set | 1 | Wuxi | Frame |

| 7 | PLC | XC3-24R-E | Set | 1 | Mitsubishi | Japan |

| 8 | Frequency converter | E600-1.5KW/380V | Set | 1 | Siemens | Germany |

| 9 | Breaker | DZ47-3P-D 20A | Set | 1 | Siemens | Germany |

| 10 | Breaker | DZ47-1P -C6A | Set | 1 | Siemens | Germany |

| 11 | AC contactor | CJX2-0910 | Set | 5 | Siemens | Germany |

| 12 | Thermal relay | JRSD-25 | Set | 5 | Siemens | Germany |

| 13 | Communication Cable | XVP-5M | Set | 1 | Mitsubishi | Japan |

| 14 | Terminal Blocks | TBC-20 | Set | 1 | Shanghai | Electric |

| 15 | Emergency stop button | 01ZS | Set | 1 | shanghai | Electrical |

| 16 | Indicator | AD16-22 | Set | 1 | Shanghai | Electrical |

| 17 | Annunciator | AD16-22SM AC220V | Set | 1 | Shanghai | Electrical |

| 18 | Touch screen | TG765-N | Set | 1 | Weinview | Taiwan |

| 19 | Proximity switch | PR18-5DN | Set | 1 | AUTONICS | Korea |

| 20 | Photoelectric switch | E3F-DS30C1 | Set | 2 | AUTONICS | Korea |

| 21 | Speed potentiometer | WTH118-1A2W4.7K | Set | 1 | Shanghai | Electrical |

| 22 | Feed cap | 180w | Set | 1 | Shanghai | Feed caps |

DETAILS SHOWING

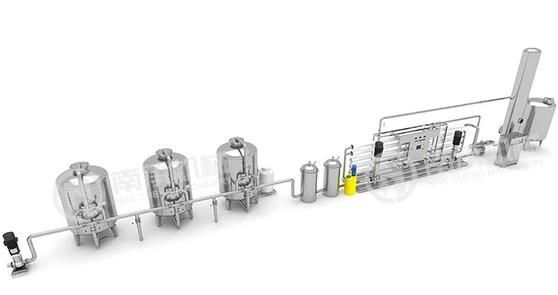

WATER TREATMENT SYSTEM

According to customer's water source analysis report and the final water standard required, we will suggest customer to choose the suitable water treatment plants.

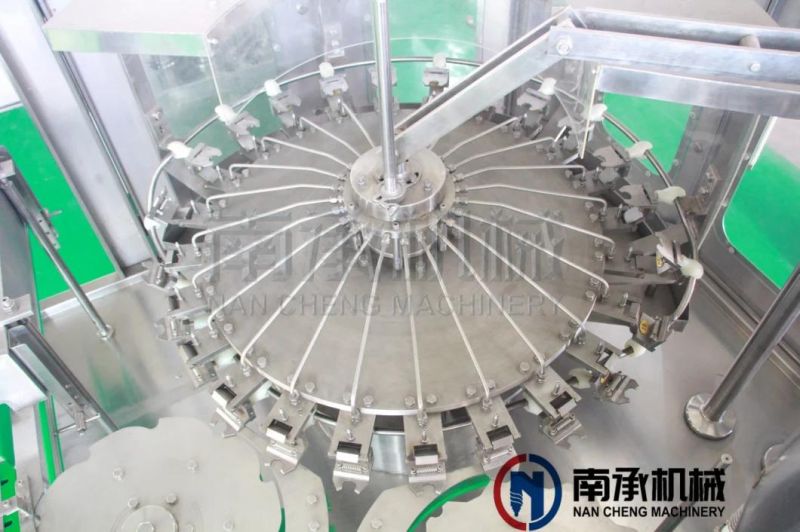

Water bottling machine main Features:

*Using the wind sent access and move wheel in the bottle directly connected technology; Canceled screw and conveyor chains, this enable the change the bottle-shaped become easier.

* Bottles transmission adopt clip bottleneck technology, bottle-shaped transform not need to adjust the equipment level, only change related the curved plate, wheel and nylon parts is enough...

* The specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of bottle mouth to avoid secondary pollution.

*High-speed large gravity flow valve filling valve, filling fast, filling accurate and no liquid lose.

*Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

*Host adopt advanced PLC automatic control technology, the key electrical components from famous company such as Japan's Mitsubishi, France Schneider, OMRON.

Packing system

As customer request and market demand, we provide the better solution for the final product package,

We have various kinds of options. Labeling machine have the PVC sleeve label, BOPP hot glue label, Adhesive stick label, Wet glue label, and packing machine have the film shrink machine and carton box package.

Blowingsystem

This machine is a fully automatic, high intelligent, stable and reliable blowing machine, with simple structure, and low energy consumption. It is very popular and well used in food, beverages, cosmetics, pharmaceutical industry.

Conveyor system

We design the factory layout based on customer factory sizes, whole line design is based on famous brand motors and automatic lubricant system, and with less power consumption, and save space.

Company introduction

Nancheng Machinery Co., Ltd. locates in Zhangjiagang city which is close to Shanghai and Wuxi. Our company covers 20,000 square meters. Supported by strong designing & developing facilities and professional technical team, we are of fully capability in research and development, manufacture and after-sale service. We never stop introducing the most advanced packing technology, developing and better our products, focusing on the reliability of overall performance; these ensure us unique competitive advantages.

The main business of our company concentrates on Water Treatment Equipment and packaging products for various commercial fluids, including drinking water, carbonated beverages, juice, tea and alcohols. We are popular with both domestic customers and overseas clients for the reliability and high quality of our products.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23