Ton Bag Shredder/ Tons Bag Shredder /Rubber Shredder/ Woven Bag Crusher

Jiangyin Join Trading Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

1834×1561×1735

Features

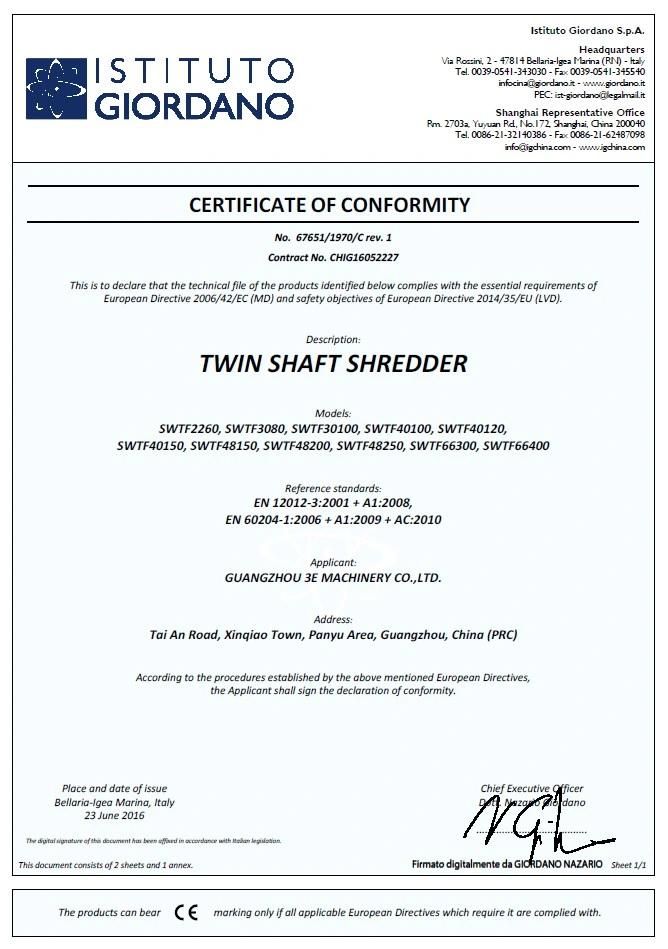

Certification

3E MACHINERY was awarded 18utility model patents and 3 invention patents.

Company profile

3E GROUP is an integrated company specialized in developing, manufacturing, distributing and providing recycling machinery solutions. Our main entity " Guangzhou 3E Machinery CO. Ltd" founded in 2003, has currently become focusing on "Shredding" and "Recycling industry" modern enterprise. Technology is the core-competitiveness of 3E Group, we are active in the recycling market and keep cooperating with well-known enterprises in Europe and the USA. Meanwhile, 3E Group keeps on improving and innovating, so far, we awarded 18utility model patents and 3 invention patents. "Efficient Economical & Environmental" is the traditional idea of 3E Group. With its own intellectual property and solid technological team, our products have been already sold to over 90 regions and countries which include the USA, Europe, Australia, Southeast Asia, Latin America, and Middle East.

Our service1.Pre-sale support

3E Machinery consists of experienced specialists, we will offer a suitable solution according client's requirement in time.

On-site inspection.

2. After-sale service

3E's skilled technicians are available to assist with onsite installation, commissioning & training on request. This will enable customers to optimize the performance of their new plant. Customers will be briefed on all aspects relating to operation and maintenance by a 3E technician. Dimensional drawings together with service requirements will be provided prior to delivery of the equipment. This will allow the customer to prepare the site and allow them to commence production in a timely fashion.

3E holds a adequately inventory of spare parts and their efficient service personnel will ensure that any required part will be dispatched without delay. Delivery of the spare parts may be by air, sea or courier depending on the urgency of the situation. Customers are encouraged to hold their own critical spare parts such as granulator blades and screens to ensure optimal machine condition and performance.

3. Technical support

3E provides enough hardware resource especially for large-scale production lines, clients can carry out installation, commissioning and acceptance before delivery.

Regular return visit.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23