Under Water Pelletizing for TPR/TPE/PP/EVA Pellets Making Machine

ShunDe Jiatian Hard Tool Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. TSE 65 Assembly Structure Integral Type Extruder Screw Twin-Screw Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized Keyword Twin Screw Extruder Application Granules Automatic Grade PLC Control After-Sales Service Provided Engineers Available to Service Machinery Overseas Material EVA/TPR/TPU//TPV/Pet/TPE Capacity 80--120kg/H Voltage 330V/220V/3p Certification CE Transport Package Wooden Case Specification TSE Trademark haisi Origin Nanjing, Jiangsu, China HS Code 84772090 Production Capacity 80-100kg/HProduct Description

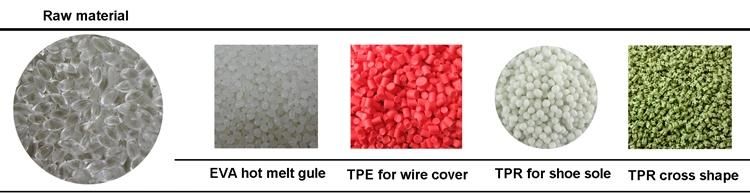

underwater plastic extrusion machine

Hot sale model of EVA underwater pelletizer:

| Mode | Diameter (mm) | L/D | speed (r/min) | Motor power (kw) | Capacity (kg/h) |

| TSE-75B | 71 | 32-64 | 600 | 132 | 400 |

Underwater Extruders

Due to its stickiness nature, hot glue is hard to cutting in traditional way, such as water-strand pelletizing, water ring, air cooling hot cutting. Therefore Haisi Extrusion adopt an advanced new cutting method--underwater pelletizing system. With the underwater pelletizer, granules come out from die head and flow into water directly, which increases the cooling efficiency, and makes the granules shaped good.

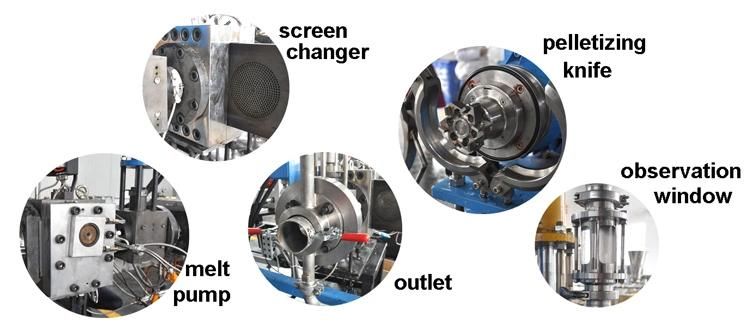

Details in underwater pelletizing line

Underwater granulation system running in customers' factory

Application for underwater production line:

Thermoplastic Elastomer TPE, TPU, TPV, TPR,TPS, POE, EVA, SBS etc. are widely used in daily life, such as tpu fabric, tpu medical gloves, tpu phone case, tpu shoe sole, tpu strap, tpv sealing and others.

Underwater pelletizing machine for Czech customer

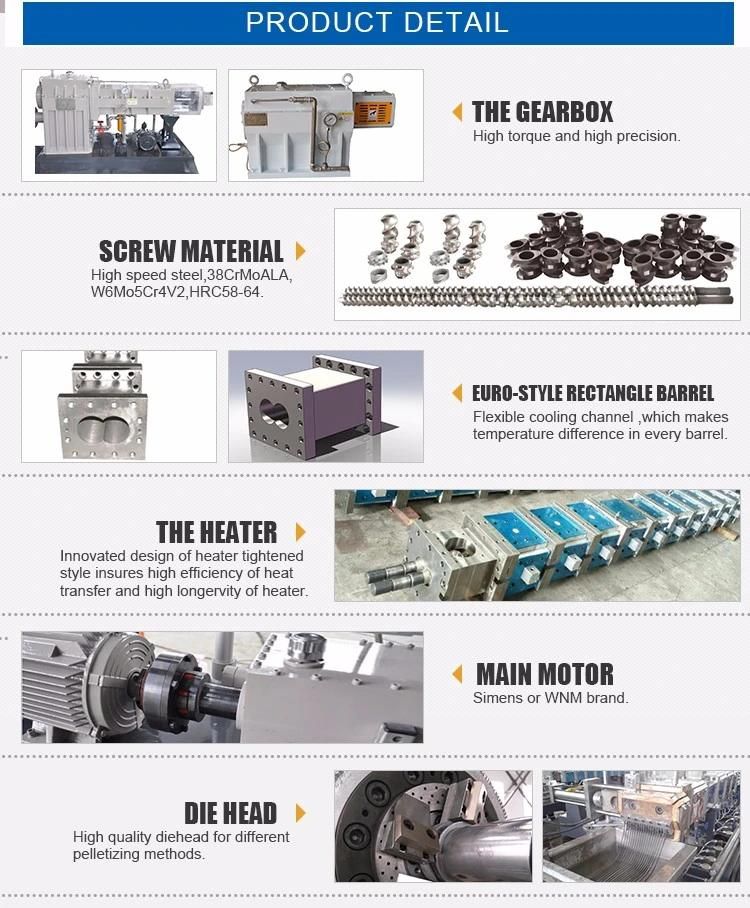

Features of our Underwater pelletizing line

About Our Company

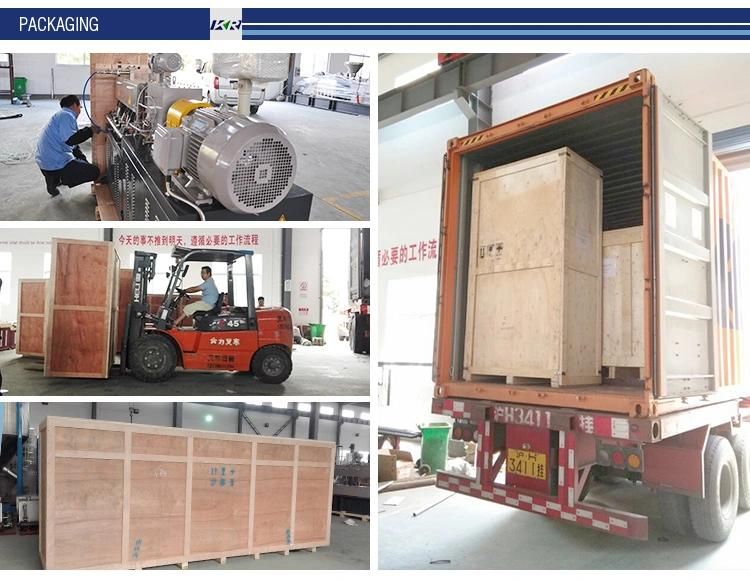

Nanjing Kairong Machinery Technology Co.,Ltd is a high-tech manufacturing and trading company in China. "Family" is our benchmark. We work efficiently and help each other whenever anyone is in need due to the same target, that is, to make best quality of extruders in China.

Company is in strict accordance with CE and ISO9001 quality certification system for production management. There are over 200 models of extruders and spare parts. Factory has CNC center, grinding machines, cutter, puncher, etc. to meet customers' requirements on extruders and spare parts.

Our machines are widely used in China mainland, and have been exported to 20 countries and places over the world. Our annual production capacity is 240 sets plastic extruder in domestic countries and abroad! OEM service offered in granulating plastic extruder industry in consistence with specific requirement from both national and international customers.

Surely you will also get professional machines and characteristic services here. Let's create more together!

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23