Plastic Water Tank Making Machine Rock and Roll Rotational Moulding Machine

HOMER ENTERPRISE CO., LTD. / 2022-07-04

=== Base Info ===

=== Description ===

Overview

Product Description

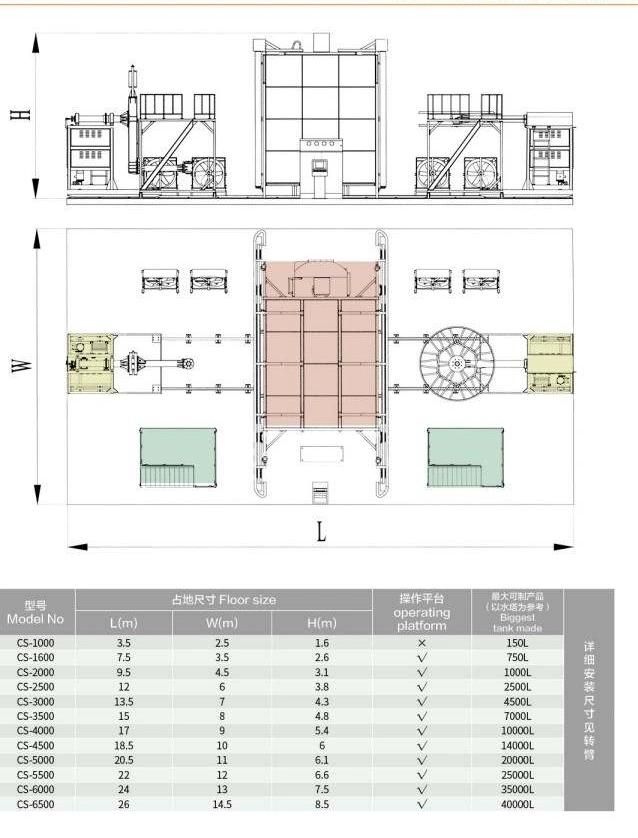

The shuttle rotomolding machine is suitable for producing relatively small batches or large-sized rotomolded products.

1.Scope of application: suitable for the production of various rotomolded products, such as: water tanks, fuel tanks, lampshades, urea tanks, pipeline wells, roadblocks, floating bodies, auto parts, kayaks, feeding systems, water tanks, septic tanks, etc Wait;

2Arm type: straight arm, L arm, C arm can be selected at will;

3. Available heat sources: natural gas, liquefied gas or diesel;

4.Efficient thermal insulation heating room, low energy consumption;

5.Each arm operates independently and does not interfere with each other;

6.Function interlock to ensure safe and stable operation of equipment;

7.Real-time monitoring of heating room temperature to ensure product quality;

8.Process recipe storage function, convenient for production management;

9. The touch interface is fully functional and easy to operate;

10.Fault self-check function, convenient for maintenance;

11. Can realize remote fault diagnosis;

The double-armed comb-type equipment is a linear combination, the middle is the combustion chamber, the cooling chamber and the loading and unloading positions are integrated on both sides. The utilization rate of the combustion chamber is high, the mechanical arm can carry heavier molds, which is suitable for manufacturing larger products, and the equipment maintenance is convenient. The size of the combustion chamber can be designed and manufactured according to customer needs.

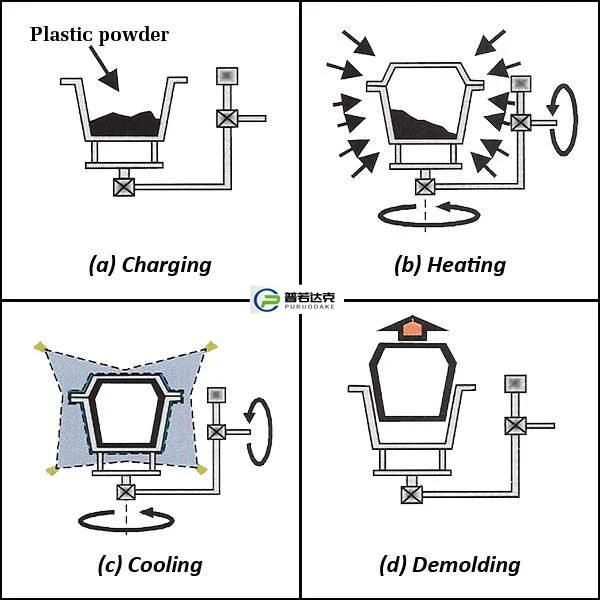

Rotomolding processing flow

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

FAQ

Nice to meet you, If you have any questions, Please feel free to contact me!

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23