Double Heads 1600*1000mm CO2 Fabric Laser Cutting Machine

Shenzhen Fortress Industry Co., Ltd / 2022-06-23

- Cooling System:Industrial Chiller Cw-5202

- Technical Class:Continuous Wave Laser

=== Base Info ===

- Model NO.:UG-1610L-2

- Applicable Material:Nonmetal

- Structure Type:Desktop

- Laser Classification:Gaseous Laser

- Laser Technology:Laser Control Fault Cutting

- Working Area:1600*1000mm

- Laser Type:CO2 Sealed-off Laser Tube

- Rated Laser Power:Reci W2 90W

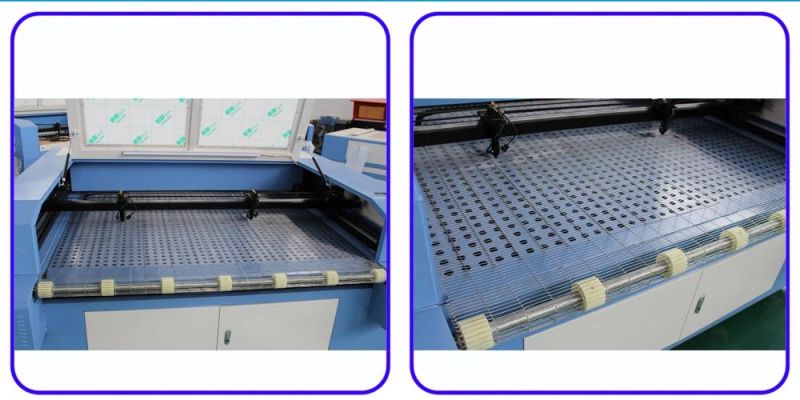

- Working Table:Honey Comb and Knife Strip Double Working Table

- Driver and Motor Type:Yako Three Phases Stepper Motor and Driver

- Laser Head Number:2

- Guide Rail:Linear Square Guide Rail

- Cutting Speed:0-10000mm,Min

- Control System:Trocen Awc708c

- Software:Lasercad

- Transport Package:Plywood Case

- Specification:2320*1690*1290mm, 500kgs

- Trademark:UPGOAL

- Origin:China

- HS Code:8456110090

- Production Capacity:250set Per Month

- Package size per unit product:232.00cm * 169.00cm * 129.00cm

- Gross weight per unit product:500.000kg

=== Description ===

Basic Info.

Model NO. UG-1610L-2 Applicable Material Nonmetal Structure Type Desktop Laser Classification Gaseous Laser Laser Technology Laser Control Fault Cutting Working Area 1600*1000mm Laser Type CO2 Sealed-off Laser Tube Rated Laser Power Reci W2 90W Working Table Honey Comb and Knife Strip Double Working Table Driver and Motor Type Yako Three Phases Stepper Motor and Driver Laser Head Number 2 Guide Rail Linear Square Guide Rail Cutting Speed 0-10000mm/Min Control System Trocen Awc708c Software Lasercad Transport Package Plywood Case Specification 2320*1690*1290mm, 500kgs Trademark UPGOAL Origin China HS Code 8456110090 Production Capacity 250set Per MonthPackaging & Delivery

Package size per unit product 232.00cm * 169.00cm * 129.00cm Gross weight per unit product 500.000kgProduct Description

Double Heads 1600*1000mm Co2 Fabric Laser Cutting Machine

Features

Auto material-feeding platform

Caterpillar band type auto material-feeding platform with new type flat flex belts with strong absorption for wool fabric, realizing continuous feeding and cutting with with less labor and material.

Auto edge cutting without rough edge, burr.

With Online control system, Work can be loaded from the Cloud.

Fabric Presser

Fabric is adsorbed onto the working table ensured materia is fed steadily without creases curled edges.

Laser Head

Newly design, More in according with mechanical engineering. Safe and Durable. Simple Operation with high engraving/cutting speed and high laser power convert ratio.Double laser heads, improving working efficiency.

Double laser head, imporving the working efficiency.

Laser Tube

Adopted famous Reci W2 Co2 laser tube for each head, rated power: 90W, peak power: 100W, long time time and stable

Working Table

SUS304 stainless steel Strips: With oxidation treatment and low reflection ratio Ensured cutting quality

Beam Path System

Adopting imported focus lens with high lusciousness and mirror with high reflective ensure stable power transference.

Motion System

Imported High precision,low friction force and stand wear and tear linear square guide rails and blocks with 3M belt ensured stable transmission, lower noise.

Operation System

Advanced USB port Trocen AWC708WC special auto feeding control system with large inner memory device and Fast rectilinear cutting and Optimized shortest path function, Greatly improved the working efficiency.

With full-process automatic laser power attenuation compensation , ensuring the performance consistency of engraving/cutting. The High speed motion control program with pre-buffering function enhances productivity more.

Completely compatible with various CAD&CAM softwares such as AuotCAD, CorelDAW, supporting the desgins directly exporting. With advanced Color management and defining the working turns with different colors , All or a part work can done in one time.

Rationalized placement of the electronic parts Optimized heat dissipation effect.

Cooling system

Industrial chiller CW-5202

Technical Parameters

ffective working area | 1600*1000mm |

Laser Type | Co2 sealed-off laser tube |

Laser head number | Double |

Laser tube power | W2 series, Reci, Beijing (Rated power: 90W, max. Power: 100W) 2 pcs |

Working table | SUS304 stainless steel strip auto feeding working table |

Driver mode | 3 phases stepper motor and Driver, Yako brand |

Guide rail | Linear square guide rail ( Hiwin,Taiwan) |

Transmission | Belt transmission |

Control panel | English |

Laser output control | 1-100% software setting |

Engraving speed | 0-60000mm/min |

Cutting speed | 0-10000mm/min |

Control system | Trocen AWC708C |

Control software | LaserCAD |

Design software when delivery | CorelDraw |

Control panel | DSP offline |

Resolution accuracy | < 0.01mm |

Location precision | < 0.01mm |

Highest scanning accuracy | 2500DPI |

Type of cooling | Industrial chiller CW-5202 |

Water protection system | Yes |

Blow-off system | Air pump for the laser head Air blower for the machine |

Biggest scanning accuracy | 2500DPI |

Working temperature | 0-45 °C |

Operating humidity | 5-95% (without condensed water) |

Voltage | AC 220V ±10%,50/60Hz, single phase or |

Supporting picture format | PLT,DST,DXF,BMP, DWG,AI,LAS,etc |

Certificate | CE/FDA |

Applications

A variety of fabrics can be cut into any graphics precisely which can be made into Sofas, tents, umbrellas, clothing, leather, soft cloth (cloth, leather, plush), car interior (seat covers, floor mats, cushion).

Reference Working Videos

https://upgoalcnc.en.made-in-china.comyInEaDg01cVvL

Reference Sample Photos

For more information, just feel free to contact us!

Jinan Upgoal Mechanical Equipment Co.,Ltd

upgoalcnc.en.made-in-china.com, Mob: +86-13869132173

CNC Router/Laser Engraving Cutting Marking Machine/Plasma Cutting Machine

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23