Plastic Recycling Pyrolysis Plant

Ningbo Yinzhou Evershine Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

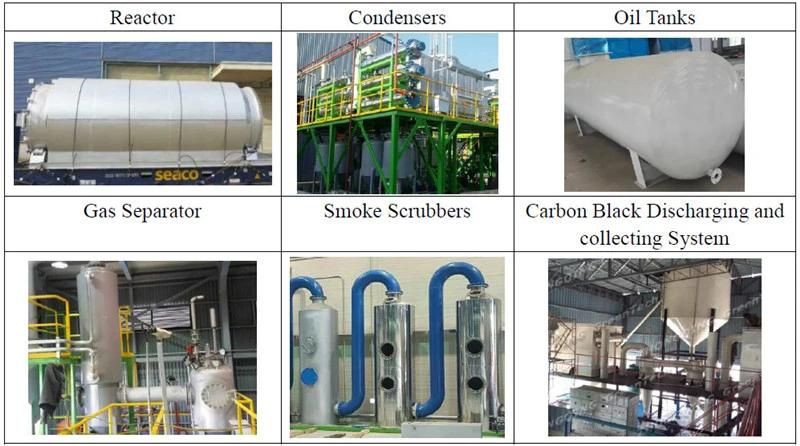

2. Main Parts of the Plastic Recycling Pyrolysis Plant

or chemical industries or hotels, restaurants etc. as fuel oil, or used

for heavy oil generators to get electricity.

5. Delivery and Packing OF the Plastic Recycling Pyrolysis Plant:

+70% before shipment

- 2m diameter: 2~3*40HQ

- 2.6meter diameter:1*40'Fr+2*40 HQ

- Weight: 20MT~30MT

- All goods are packed with export standard package to make sure no damage during transportation.

6. Outstanding Features of our the Plastic Recycling Pyrolysis Plant:

- Full open door design: Speedy loading in and steel pulling out; Easily cooling down after one batch finished, saving time; No leaking with special high temperature flexible graphite packing.

- Unique Craft Condensers: High condensing efficiency with more oil output. Good quality oil, longer lifetime, and easy to clean.

- Unique Smoke Scrubbers: More efficient removal of the acid gas and dust of the smoke by neutralization, purification and absorption, environmental friendly without pollution.

- Carbon Black Discharging System: Speedy fully enclosed Auto-discharging under high temperature, avoiding carbon black pollution, saving time.

- Automatic Submerged welding technology, ultrasonic nondestructive testing, both manual and the automatic safety devices.

- Sync Gas Recycling System: Fully burned after recycling and utilization, saving fuel and preventing pollution.

- Direct Heating System: Enlarging heating square to lengthen the lifespan of the reactor and easy to control the temperature.

8. Our Certificates:

9. Sales after service:

- Quality warranty period: One year warranty for the reactor ,and lifetime maintenance for complete set of machines. pay the double air tickets, accommodation and food.

- According to the requirement of the buyer, our company sends engineers for installation and commissioning in buyer's site including the training of skills of buyer's workers on operation, maintenance, etc.

- Supply layout according to buyer's workshop and land, civil works information, operation manuals, etc. to the buyer.

- For the damage caused by the users, our company provides the parts and accessories with cost price.

- Our factory supplies the wearing parts with the cost price to clients.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23