Turnkey Project Plastic Water Ring Cutting Pelletizing Machine Line

Chenguang Machinery & Electric Equipment Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Throughput Rate (kg/h)

Efficiency Volume

(Liter)

Motor Power

(KW)

Diameter of screw

(mm)

L/D

Motor Power

(KW)

BX-80

300

37

80

33

45/55

160-220

BX-100

500

55

100

33

90/110

300-380

BX-120

800

90

120

33

132

450-480

BX-130

1000

110

130

33

160/185

500-650

BX-160

1200

132

160

30

220/250

800-1000

BX-180

1400

315

180

30

315

1000-1200

5. PE PP Film/bags double stage granulating line layout:

1.Conveyor belt → 2.Semi automatic metal detector →3.Compactor machine→4.The first stage extruder→5.hydraulic screen changer→6.the second stage extruder →7.hydraulic screen changer →8.Die face cutting system→9.Water cooling tank→10.Centrifugal dewatering machine→11.Vibrator screen machine→12.Air conveyor & Storage silo

6. Details for PP PE film Plastic Recycling Machine :

Function: as standard design, plastic scraps such as film, filament, raffias conveyed into the compacting room through belt conveyor; to handle rolls' scraps, roll hauling off device is an optional feeding method. Motor drives of conveyor belt and hauling device cooperate with ABB inverter. Feeding speed of conveyor belt or roll hauling off is fully automatic based on how full the compactor's room is. Metal detector can be combined with belt conveyor, and can interlock with control system, to warn and stop the system, in case that metal is found in feeding section

Function: the rotatory blades of compactor will cut up incoming scraps. Frictional heating which caused by high speed rotatory blades will heat and let scraps shrinking just below their agglomerating point. Optimal designed guide structure compacts the material and directs it into extruder screw. Crushes, dries and compacts the material which enables a fast and stable feeding from the compactor directly into the extruder.

Function: A specialized single screw extruder applied to gently melt the pre-compacted material. The plastic scraps will be well melted, plasticized in a 32 to 34D processing section. With double-zone vacuum degassing system, volatiles such as low molecular and moisture will be removed efficiency, especially suitable to heavy printed film and material with some water content.

Function: Our cutting system is an advantage. Both PE film and PP woven&non-woven material can get into pellets with excellent quality.

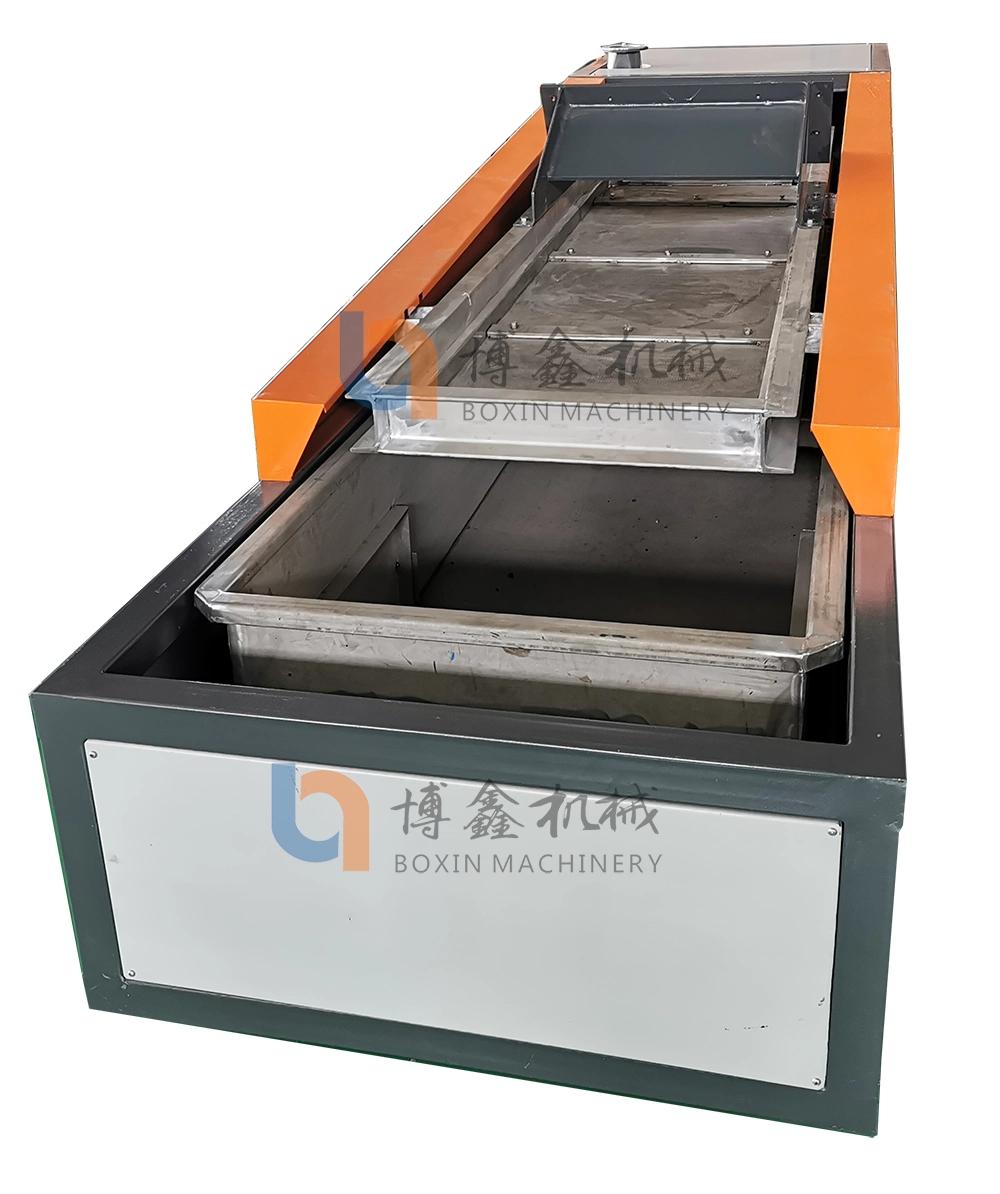

Function: Remove the unqualified particles and remove the moisture. Our latest design of the vibration and dehydration integrated machine is not only beautiful in appearance but also the practical can be more effective.

7. Feature for plastic film recycling machine:

1. Die-face water ring pelletizing system is a standard pelletizing method,

2. Self-adjusting pelletizing,

3. RPM of rotator blades is automatic based on melt extruding pressure,

4. Dewatering vibration sieve combining with horizontal-type centrifugal dewatering have a good drying efficiency.

8.Quality Control (Plastic Extruder pelletizing machine)

· We have technical, engineer team design the sample machinery before enter into market

· Production QC team ensure the machine manufacturing quality

· We will running every machine after finished before shipment

· Optional choose by client running the machinery by material

9. Service System( noodle making machine )

· Pre-sale: We given client the details technician offer, sign the sales contract etc.

· In-sales: We supply the details layout, installation instruction, technician support for the clients;

· After sales: We arrange engineer to install the machinery and training the workers for client;

· We have 24hours team to solve the after sales problem;

· We have free spare parts with the machine;

· We supply long term spare parts for every customer

· We always up date the new technology to every customer

Feel free to contact us at any time!

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23