PVC Ceiling Plate Plastic Panel Board Sheet Extrusion Machine Line

Dongguan Yize Precision Cutting Tool Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

PVC/WPC Board Extrusion Line

Applying specially-designed SJSZ conical twin screw extruder, this production line is mainly used for production of construction board, wide door panel, cabinet board, indoor/outdoor decoration material, etc. The whole production line includes conical twin screw extruder, vacuum calibration table, haul-off unit, cutting unit, stacker, as well as other optional auxiliary units. With powerful chiller to guarantee the calibration effect of the door panel, the extrusion output of this line can reach 600kg/h up to 1250kg/h.

International brand speed governor, bearing the advantages of wide governing range, high temperature control precision, convenient and reliable operation, etc.

Caterpillar haul-off unit adopts precision reduction motor, with speed controlled by inverter. It has the advantages of reasonable structure, large traction power, stable hauling, etc.

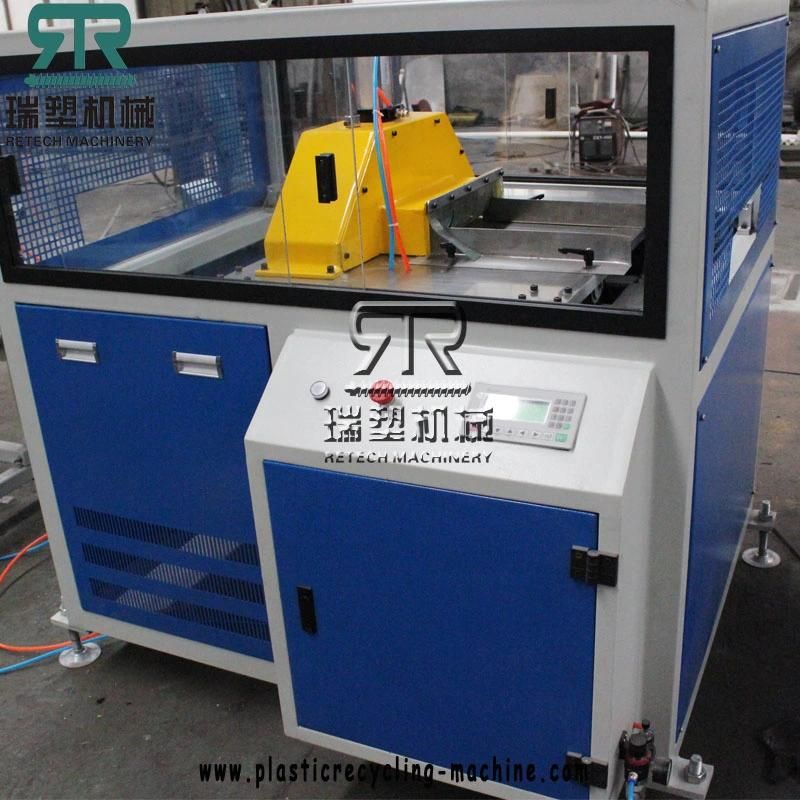

Cutting unit bears the advantages of reliable working, high-precision cutting, etc. PLC programming control or famous domestic brand controlling system is adopted for the auxiliary units, which is stable and reliable.

Main Parts of a Plastic PVC Board Extrusion Line:

Extruder:

Mould and Calibrator::

Haul Off Machine:

Sticker Film Laminator:

Cutter and Stracker:

If you are interesting more details of our products, please contact with us no hesitation!

plasticmachine.en.made-in-china.com

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23