Professional Supplier Metal Fiber Laser Cutter Machine for Automobile Cutting

Yuhuan Green Island Plastic Packaging Factory / 2022-06-23

- Application:Home Appliance, Environmental Equipment, Petroleum Machinery Manufacturing, Agriculture Machinery, Aerospace Industry, Automotive Industry, Advertising Industry

- Cooling System:Water Cooling

- Technical Class:Continuous Wave Laser

- Applicable Material:Metal

- Structure Type:Gantry Type

- Laser Classification:Semiconductor Laser

=== Base Info ===

- Model NO.:993

- Laser Technology:Laser Vapor Cutting

- Model No.:Dpl-3015-1000I

- Type for Cutting Machine:Laser Cutting Machine

- Automation:Automatic

- Type:Laser Cutting Machine

- Laser Wavelength:1070nm

- Applicated:Machinery & Hardware

- Certification:SGS, Ce, ISO 9001:2000

- Condition:New

- Medium of Laser:Semiconductor Pump Continuous Ytterbium Doped Fibe

- Export Markets:Global

- Transport Package:Wooden Box

- Specification:CE, SGS

- Trademark:Dapeng Laser

- Origin:Shenzhen, China

- HS Code:84561000

- Production Capacity:650,Year

=== Description ===

Basic Info.

Model NO. 993 Laser Technology Laser Vapor Cutting Model No. Dpl-3015-1000I Type for Cutting Machine Laser Cutting Machine Automation Automatic Type Laser Cutting Machine Laser Wavelength 1070nm Applicated Machinery & Hardware Certification SGS/ Ce/ ISO 9001:2000 Condition New Medium of Laser Semiconductor Pump Continuous Ytterbium Doped Fibe Export Markets Global Transport Package Wooden Box Specification CE/ SGS Trademark Dapeng Laser Origin Shenzhen, China HS Code 84561000 Production Capacity 650/YearProduct Description

Professional supplier metal fiber laser cutter machine for automobile

Shenzhen DAPENGLaser Technology Co., Ltd.

Headquartered in Shenzhen, the company operating layout covering the East Coast Main industrial provinces and cities: Guangzhou, Foshan, Zhongshan, Jieyang), Fujian (Xiamen), Wenzhou, Zhejiang, Ningbo), Jiangsu (Wuxi), Shandong (Qingdao) and the Indian agent, vertical integration of upstream and downstream production process, diversification of laser equipment, products, production elasticity, effectively shortening the supply chain and meet the needs of customers purchasing, reduce time and cost of procurement.

Dapeng laser Dedicated in R & D, manufacturing, sales of industrial laser equipment, the main products of the company including laser marking machine series, laser welding machine, laser cutting machine series, specially used in the industry and automatic customization of laser equipment, at the same time, it provides parts of lasers and related equipment for the Chinese and global laser industry manufacturers. In selling all kinds of laser equipment more than 4000 units, is the domestic well-known from research and development, raw material procurement, production, distribution and after-sales and a series of full set of professional service of laser equipment manufacturers and sales of its products covers mainland China, Taiwan, Southeast Asia, India, Japan, Korea, Europe and the United States, and actively expand in Eastern Europe, the Middle East, Eurus, South America and other emerging markets.

Dapeng laser is committed to provide stability is the highest and most of the price ratio of industrial laser equipment for the customer, Guangdong Dapeng LNG Company products both in performance, stability, the warranty period and price relative to the companies in the same industry products has incomparable advantages. Is one of the leading brands in China's standard laser marking machine, welding machine and cutting machine. 2005, officially entered the laser equipment industry, after 10 years of hard work to cultivate, Dapeng laser has been among the well-known industrial laser equipment manufacturers, the company has experience of 10 years of professional R & D design team, for the industry to develop customized non-standard automation laser equipment. We are committed to become the field of industrial laser equipment total solution provider, for customers to provide high-quality, high stability, high price of industrial laser equipment and a full range of technology support service.

Our professional services:

1. Provide service from a full package of materials and equipment research and development, proofing, automation of laser equipment design.

2. the perfect pre-sale, sale and customer service service system.

3.Customer satisfaction guarantee commitment.

DAPENGLaser Cutting Department

The cutting department built bused on our R&D Engineer team in 2015,and we have provide over 200 Laser cutting machines to our customers and our equipments and technical service are proved by our customers.

The DAPENGLaser cutting machine are widely used in crafts, electronics, toys and other industries, used in sheet metal, metal products, jewelry, nameplate, advertising, packaging steel structure, precision machinery, auto parts, glasses, and other industries. For the stainless steel plate, iron plate, aluminum, ceramics, silicon and diamond cutting. Can also be metal, a variety of non-metallic materials, pipe cutting

HOW LASER CUTTING WORKS

Laser cutting is a technology that uses a laser to cut materials, and is typically used for industrial manufacturing applications, but is also starting to be used by schools, small businesses, and hobbyists. Laser cutting works by directing the output of a high-power laser most commonly through optics. The laser optics and CNC (computer numerical control) are used to direct the material or the laser beam generated. A typical commercial laser for cutting materials would involve a motion control system to follow a CNC of the pattern to be cut onto the material. The focused laser beam is directed at the material, which then either melts, burns, vaporizes away, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish. Industrial laser cutters are used to cut flat-sheet material as well as structural and piping materials.

DP FIBER LASER CUTTING ADVANTAGES:

1, Cost saving on power consumption/ only 20-30% of co2 laser cutting machine under same power.

2, Flexibility and precision cutting of simple or complex parts

3, Adopts imported world brand fiber laser/Life time over 100,000hrs

4, Imported servo motor and gearing system ensure precision cutting

5, High quality cut with no extra finishing required

6, Higher cutting speed and efficient, speed of cutting plate over 15 meters per minute

7, Non contact cut which means no marks or contamination of the material

8, Ability to cut virtually any sheet metal

Technical parameter:

| Model | DP-L Fiber laser cutting machine |

| Laser Power | 1000w1500w/2000w IPG laser source |

| Working Area | 1300*2500mm (1500*3000mm optional) |

| Laser Wave Length | 1064nm |

| Working Table | Sawtooth |

| Maximum Idle Running Speed | 3000mm/s |

| Position Accuracy | ±0.001mm/m |

| Position Speed | 20m/min |

| Minimum Line Width | ± 0.02mm |

| Cutting Thickness | ≤16mm (carbon steel) |

| Control System | Cypcut |

| Position Type | red dot |

| Power Consumption | ≤16KW |

| Working Voltage | 380V/50Hz |

| Auxiliary Gas | oxygen,nitrogen,air |

| Working life of fiber module | More than 100000 hours |

| Fiber laser cutting head | Germany Precitec |

| Focus lens | Lasermech made in USA |

| Driver system | Imported servo motor |

| Liner guider system | PMI made in Taiwan , (Option THK made in Japan) |

| Transmit system | Dual Rack & Pinion type |

| Rack system | Herion made in Germany |

| Chain system | Igus made in Germany |

| Warranty time | Whole machine for 1 years (domestic fiber module 1 years, |

| imported IPG 1 years ) | |

| Delivery time | 30 days |

| Gross weight | 4500kg |

APPLICABLE MATERIALS:

Stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized sheet and other metal pipes and tubes.

APPLICABLEINDUSTRY:

It is widely applied in industrial pipeline processing, explosion-proof equipment, military industry, chemical industry, oil exploration, lamps and

lanterns, metal processing, ironware, building, etc.

Pre-sale service:

1. Free sample making:

For free sample making/testing, please send your samples or products CAD Graphics to our company in China. Sample shipping back cost should be paid by purchaser.

2. Progressing Solution Design:

According to customer's product processing requirement, we can design the unique solution that supports higher manufacturing efficiency and better processing quality for customer.

HOW LASER CUTTING WORKS

Laser cutting is a technology that uses a laser to cut materials, and is typically used for industrial manufacturing applications, but is also starting to be used by schools, small businesses, and hobbyists. Laser cutting works by directing the output of a high-power laser most commonly through optics. The laser optics and CNC (computer numerical control) are used to direct the material or the laser beam generated. A typical commercial laser for cutting materials would involve a motion control system to follow a CNC of the pattern to be cut onto the material. The focused laser beam is directed at the material, which then either melts, burns, vaporizes away, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish. Industrial laser cutters are used to cut flat-sheet material as well as structural and piping materials.

DP FIBER LASER CUTTING ADVANTAGES:

1, Cost saving on power consumption/ only 20-30% of co2 laser cutting machine under same power.

2, Flexibility and precision cutting of simple or complex parts

3, Adopts imported world brand fiber laser/Life time over 100,000hrs 4, Imported servo motor and gearing system ensure precision cutting 5, High quality cut with no extra finishing required

6, Higher cutting speed and efficient, speed of cutting plate over 10 meters per minute 7, Non contact cut which means no marks or contamination of the material

8, Ability to cut virtually any sheet metal

Technical parameter:

| Model | DP-L Fiber laser cutting machine |

| Laser Power | 1000W/1500W/2000W IPG laser source |

| Working Area | 1300*2500mm (1500*3000mm optional) |

| Laser Wave Length | 1064nm |

| Working Table | Sawtooth |

| Maximum Idle Running Speed | 3000mm/s |

| Position Accuracy | ±0.001mm/m |

| Position Speed | 20m/min |

| Minimum Line Width | ± 0.02mm |

| Cutting Thickness | ≤6mm |

| Control System | Cypcut |

| Position Type | red dot |

| Power Consumption | ≤12KW |

| Working Voltage | 380V/50Hz |

| Auxiliary Gas | oxygen,nitrogen,air |

| Working life of fiber module | More than 100000 hours |

| Fiber laser cutting head | Germany Precitec |

| Focus lens | Lasermech made in USA |

| Driver system | Imported servo motor |

| Liner guider system | PMI made in Taiwan , (Option THK made in Japan) |

| Transmit system | Dual Rack & Pinion type |

| Rack system | Herion made in Germany |

| Chain system | Igus made in Germany |

| Warranty time | Whole machine for 1 years (domestic fiber module 1 years, |

| imported IPG 1 years ) | |

| Delivery time | 30 days |

| Gross weight | 4000kg |

APPLICABLE MATERIALS:

Stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized sheet and other metal pipes and tubes.

APPLICABLEINDUSTRY:

It is widely applied in industrial pipeline processing, explosion-proof equipment, military industry, chemical industry, oil exploration, lamps and

lanterns, metal processing, ironware, building, etc.

Pre-sale service:

1. Free sample making:

For free sample making/testing, please send your samples or products CAD Graphics to our company in China. Sample shipping back cost should be paid by purchaser.

2. Progressing Solution Design:

According to customer's product processing requirement, we can design the unique solution that supports higher manufacturing efficiency and better processing quality for customer.

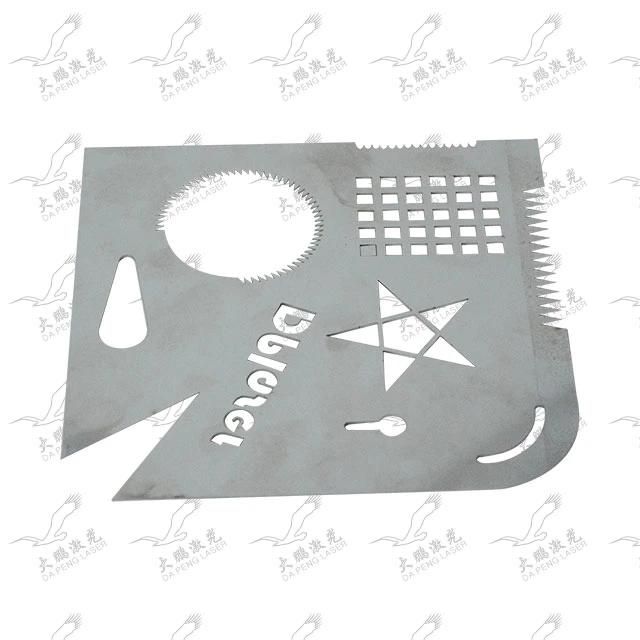

cutting sample

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23