500L 1000L 1500L 2000L 4000L 5bbl 10bbl 20bbl 50bbl Commercial Beer Conical Fermenter ...

Guangzhou Med Equipment Limited / 2022-07-05

- Condition:New

- Customized:Customized

- Voltage:110V-480V ,Customizable

- Composition:Fermentation Tank

- Processing Material:Wheat, Grape, Corn, Molasses, etc

- Process:Ferment

=== Base Info ===

- Model NO.:HEM-4000L

- Model:Hem-4000L

- Material:SUS304

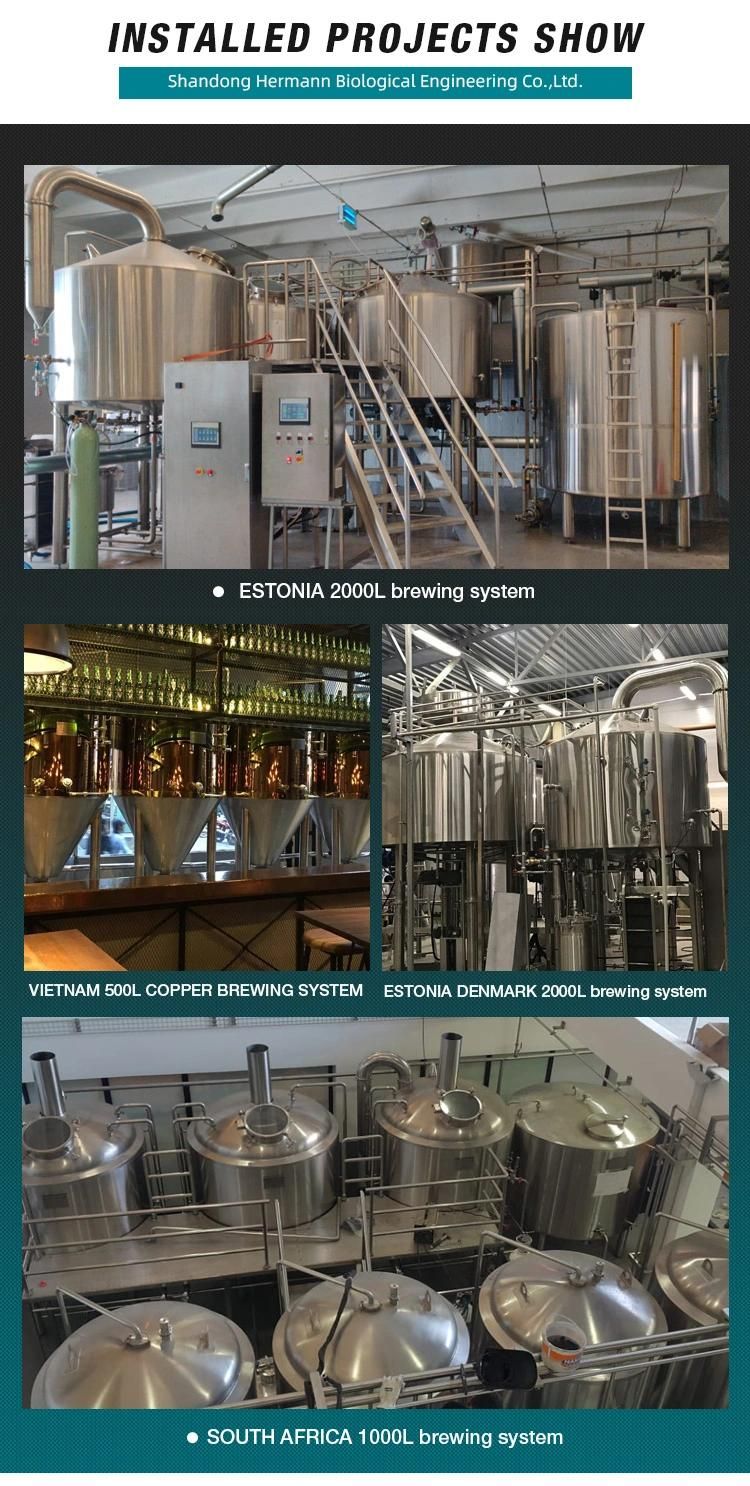

- Application:Restaurant, Bar, Hotel, Brewery

- Cooling Method:Jacket Section Cooling

- Thickness:Inner:3.0mm; External2.5mm

- Outrigger:Ø102mm*4

- Test Pressure:0.3MPa

- Working Pressure:0.2MPa

- Insulation:Polyurethane-Thickness: 100mm

- Weight:950kg

- Heat Exchange Area:4.9m2

- Transport Package:Wooden Package, Fix in Container, etc

- Specification:1000L,2000L ,3000L,4000L,5000L

- Trademark:HEM

- Origin:Shandong

- HS Code:8419899090

=== Description ===

Basic Info.

Model NO. HEM-4000L Model Hem-4000L Material SUS304 Application Restaurant, Bar, Hotel, Brewery Cooling Method Jacket Section Cooling Thickness Inner:3.0mm; External2.5mm Outrigger Ø102mm*4 Test Pressure 0.3MPa Working Pressure 0.2MPa Insulation Polyurethane-Thickness: 100mm Weight 950kg Heat Exchange Area 4.9m2 Transport Package Wooden Package, Fix in Container, etc Specification 1000L/2000L /3000L/4000L/5000L Trademark HEM Origin Shandong HS Code 8419899090Product Description

| Model | HEM-4000L |

| Capacity | Useful capacity:4000L; Gross capacity:5000L |

| Material | SUS304 |

| Application | Restaurant, bar, hotel, brewery |

| Cooling method | Jacket section cooling |

| Thickness | Inner:3.0mm; External2.0mm |

| Outrigger | Ø159mm*4 |

| Test pressure | 0.3Mpa |

| Working pressure | 0.2Mpa |

| Heat exchange area | 4.9m2 |

| Weight | 950kg |

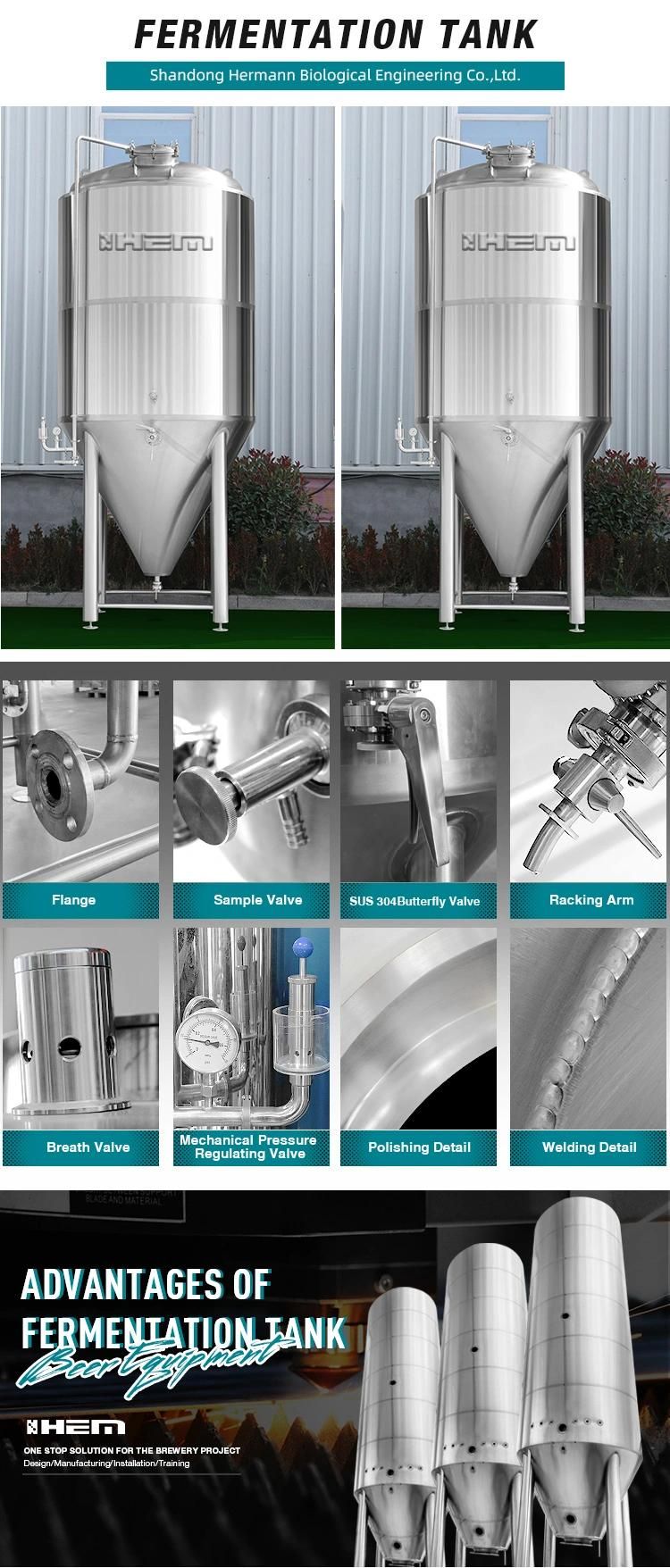

Introduction of 4000L fermentation tank :

4000L fermentation tanks suitable for hotels and restaurants and brewery. The fermentation tanks use certified

stainless steel material. All tanks and jackets inspected and pressure tested to 3 times operatiing pressure.

The dimension of the tanks can be designed according to customer's requirement. Tank design pressure is

0.4Mpa and testing pressure is 0.3Mpa.

Fermentation tank advantages :

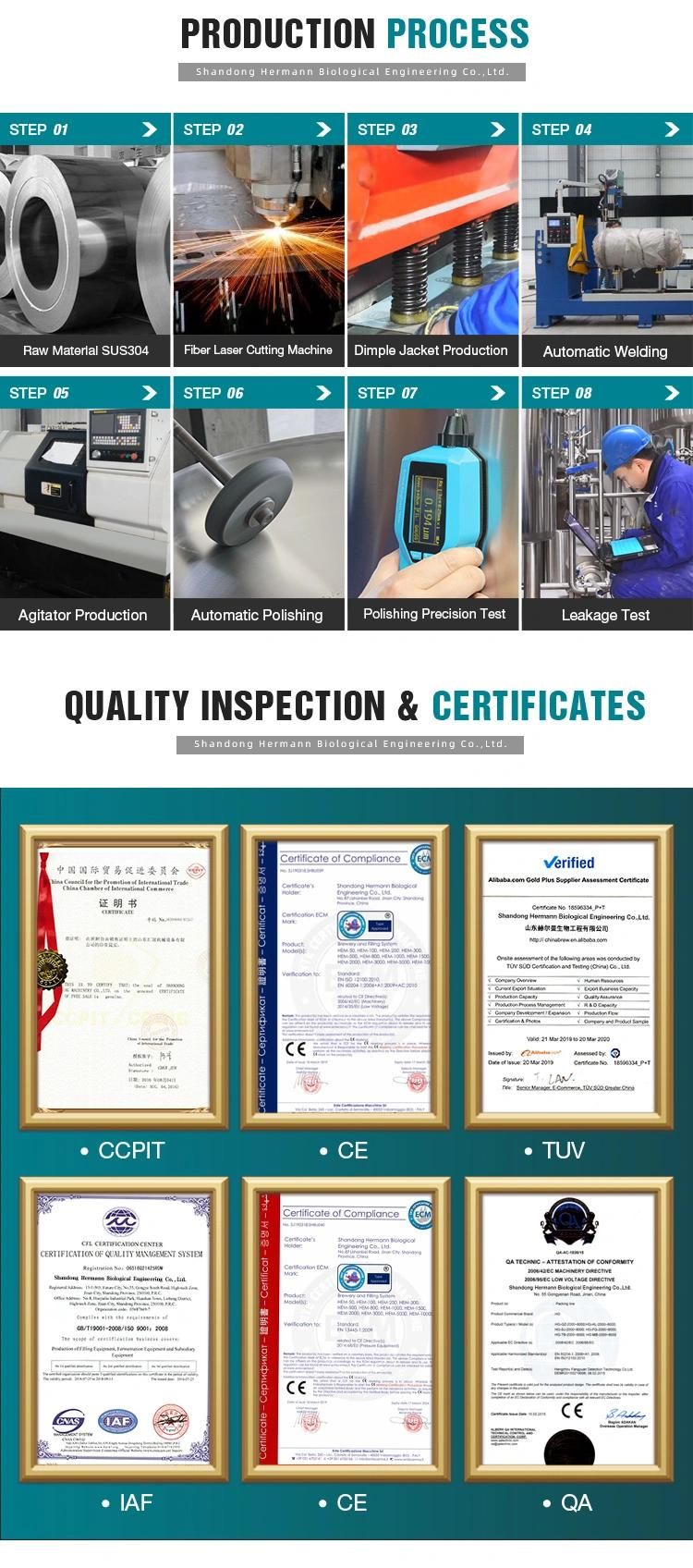

(1). 304 stainless steel plate as a whole, and our stainless steel plate manufacturer is the best in China.

(2). The cooling efficiency of Maitreya plate jacket is greatly improved.

(3). Two stage cooling mode.

(4). The insulation layer material is high-grade polyurethane with a thickness of 100mm.

(5). Polishing accuracy up to Ra0.4μ m .

(6). Strict tank pressure test.

(7). Energy conservation and pollution emissions.

| Item | Production capacity | Volume in US Gallon | Heating area | Tank diameter | Height |

| HEM-100 | 100L/day | 26US Gallon | 0.5m2 | 650mm | 1500mm |

| HEM-200 | 200L/day | 53US Gallon | 0.8m2 | 850mm | 1600mm |

| HEM-300 | 300L/day | 79US Gallon | 1.2m2 | 960mm | 1700mm |

| HEM-400 | 400L/day | 106US Gallon | 1.5m2 | 1060mm | 2000mm |

| HEM-500 | 500L/day | 132US Gallon | 1.8m2 | 1160mm | 2300mm |

| HEM-5BBL | 5BBL/day | 155 US Gallon | 1.9m2 | 1200mm | 2350mm |

| HEM-600 | 600L/day | 158US Gallon | 2.0m2 | 1220mm | 2350mm |

| HEM-700 | 700L/day | 185US Gallon | 2.4m2 | 1260mm | 2380mm |

| HEM-800 | 800L/day | 212US Gallon | 2.5m2 | 1260mm | 2400mm |

| HEM-7BBL | 7BBL/day | 216US Gallon | 2.5m2 | 1280mm | 2450mm |

| HEM-1000 | 1000L/day | 264US Gallon | 2.6m2 | 1360mm | 2500mm |

| HEM-10BBL | 10BBL/day | 310 US Gallon | 2.8m2 | 1460mm | 2700mm |

| HEM-1500 | 1500L/day | 396US Gallon | 3.2m2 | 1520mm | 2900mm |

| HEM-2000 | 2000L/day | 528US Gallon | 3.6m2 | 1560mm | 2850mm |

| HEM-2500 | 2500L/day | 660US Gallon | 3.8m2 | 1650mm | 3200mm |

| HEM-3000 | 3000L/day | 792US Gallon | 4.5m2 | 1760mm | 3800mm |

| HEM-4000 | 4000L/day | 1057US Gallon | 4.9m2 | 1900mm | 4100mm |

| HEM-5000 | 5000L/day | 1320US Gallon | 7.2m2 | 1960mm | 4400mm |

FAQ:

Q: Are you a manufacturer?

A:Yes, We have more than 20 years in brewing and beer filling equipment.

Q: What is your available port of shipment?

A: Qingdao, Tianjin, Ningbo, Shanghai.

Q: How could we confirm the details of the products?

A: We will provide all the drawings for you to confirm before production.

Q: How long the warranty will be?

A: 3 years warranty for the whole tank and the main equipment, 1 year warranty for filling machine,1 year

for the accessories and auxiliaries.

Q: How about the installation and training?

A: We can supply the installation and training. There are two options. The first option: We could appoint

our engineer to your company to debug and repair, as for the cost of this trip such as ticket, visa,

accommodation and labor cost shall be on your side. The second option: On-line service will be provided.

If still under guarantee period, the necessary accessories and parts will be provided free, the buyer afford

the transportation cost.

Q: How do you guarantee the filling machine operation?

A: Before the delivery, we will test and debug all machines in good condition and record the video for your

checking.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23