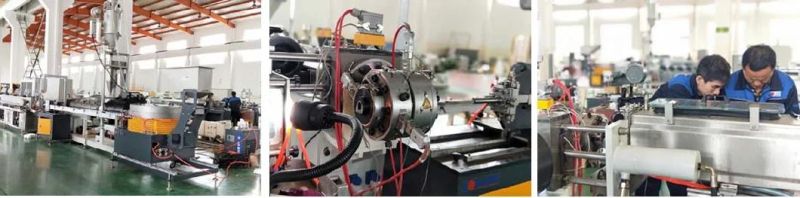

Round Drip Irrigation Pipe/Tube Making Machine /Pipe Production Line/Pipe Extruder

Nanjing Lite Hydraulic Technology Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Round drip irrigation pipe extrusion line configuration:

Main features of the round drip irrigation pipe extrusion line:

Dripper sorting & conveying system

This drip irrigation pipe line adopted centrifugal screening device for drippers screening & sequence. With below advantages,:

(1)High precision screening

(2) Dripper identifying speed 400pcs/min

which ensure the precise dripper supply during high speed production.

Punching system

(1)The round drip irrigation pipe line adopted mechanical punching mode, automatically tracking the pipe production speed, guaranteed the accuracy of punching position.

(2)2 or 4 or 6 Holes punching

(3) Punching speed: 400pcs/min

Synchronous control

The synchronous control is realized from dripper feeding, screening & sequence, conveying & inlaid, haul-off, to punching and coiling, which ensures the precise control and stable running of high speed production.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23