Automatic Laser Auto Welding Machine for Home Appliances Production Line

Bestpoly (Xiamen) Plastic Co., Ltd / 2022-06-23

- Application:Automotive Industry, Manufacturing Industry, Digital 3c Industry

- Technical Class:Continuous Wave Laser

- Control:Automatic

- Power Density:Deep Fusion Welding

- Laser Classification:Semiconductor Laser

- Type:Optical Fiber Transmission Laser Welding Machine

=== Base Info ===

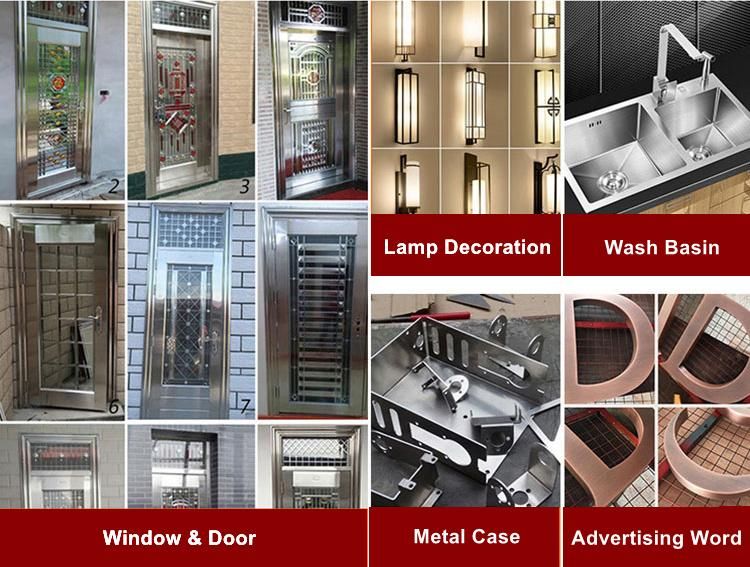

- Application 1:Cabinet Kitchen and Bathroom

- Application 2:Stair Elevator and Shelf

- Application 3:Oven and Stainless Steel Window Door

- Application 4:Window Guardrails and Distribution Boxes

- Power Rate:500W 1000W 1500W

- Wavelength:1070nm

- Fiber Length:8-10m

- Working Type:Continous, Modulation

- Welding Speed:0-120mm,S

- Welding Thickness:0.5-5mm

- Welding Gap:Less Than 0.5mm

- Cooling Chiller:Industrial Chiller

- Working Temperature:15-35 Centi Degree

- Working Humidity:Less Than 70%, No Condensation

- Power Supply:220V 50Hz

- Transport Package:Wooden Case

- Specification:600Kgs

- Trademark:CCILASER

- Origin:China

- HS Code:8515809090

- Production Capacity:20 Sets Per Month

=== Description ===

Basic Info.

Application 1 Cabinet Kitchen and Bathroom Application 2 Stair Elevator and Shelf Application 3 Oven and Stainless Steel Window Door Application 4 Window Guardrails and Distribution Boxes Power Rate 500W 1000W 1500W Wavelength 1070nm Fiber Length 8-10m Working Type Continous/ Modulation Welding Speed 0-120mm/S Welding Thickness 0.5-5mm Welding Gap Less Than 0.5mm Cooling Chiller Industrial Chiller Working Temperature 15-35 Centi Degree Working Humidity Less Than 70%/ No Condensation Power Supply 220V 50Hz Transport Package Wooden Case Specification 600Kgs Trademark CCILASER Origin China HS Code 8515809090 Production Capacity 20 Sets Per MonthProduct Description

1. Feature:The laser welding machine can achieve spot welding, butt welding and precision welding of thin-walled material and precision parts.

The laser power is powerful. The welding bead depth ratio is high and the heat affected scope is small. The deformation is small and welding speed is fast.

The welding work is smooth and professional. It is the optimum equipment for welding auto parts, lithium-ion battery, mobile phone parts, electronic parts and so on.

2. Advantage:

2.1 Laser welding can achieve spot welding, butt welding, overlay welding, sealing welding, etc. for thin-walled materials and precision parts.

2.2 The laser power is large, the weld has a high aspect ratio, the heat affected area is small, the deformation is small, and the welding speed is fast.

2.3 The weld quality is high and flat, no porosity, and the toughness of the material after welding is at least equivalent to the parent material.

2.4 Humanized design, LCD display, centralized button operation is simpler.

2.5 Four-dimensional ball screw workbench adopts imported servo control system and optional rotary table. It can realize automatic welding such as spot welding, linear welding and circumferential welding. It has wide application range, high precision and fast speed.

2.6 The current waveform can be adjusted arbitrarily, and different waveforms can be set according to different welding materials, so that the welding parameters and welding requirements are matched to achieve the best welding effect.

3. Application:

It is widely used in aviation, machinery, electronics, mobile phones, communications, chemicals, electrical appliances, hardware, automotive manufacturing.

Auto parts: hydraulic ejector, filter, sensor, solenoid valve, etc.

Lithium-ion battery: extreme materials, cylindrical caps, etc.

Mobile phone industry: mobile phone backplane, studs, card slots, etc.

Electronic industry: sensors, motor rotors, capacitors, relays, etc.

Kitchen and bathroom appliances: kettle, faucet, hook, sink, range hood, etc.

4. Case:

4.1 Manufacturing Industry.

Laser welding technology is widely used in auto industry.

4.2 Digital 3C industry

Laser welding has been widely used in the digital 3C industry, especially in the mobile phone microelectronics industry.

4.3 Medical industry

The welding seam of the laser welding machine for medical equipment is smooth and beautiful, and will not cause deformation of the welded product.

5. Welding Effects:

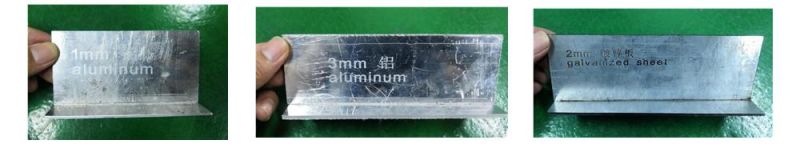

5.1 Laser Welding Machine for Carbon Steel/ Stainless Steel

5.2 Laser Welding Machine for Aluminium/ Galvanized Sheet

5.3 Laser Welding Machine for Copper

6. Technial Parameters

Model No. | LW-3-1000W/1500W/2000W |

Working model | automatic type |

Laser Power | 1000W/1500W/2000W JPT/MAX/IPG/RAYCUS |

Welding area | 200*200/ 300*300mm |

Spot Size | 0.2-1.8mm |

Welding depth | 0.8-1mm |

Laser Wave Length | 1064nm |

Impulse Width | ≤10ms |

Laser Cooling | Water cooling |

Water cooling | CW1000/1500W/2000W |

Total Power | <5KW |

7. Company Introduction

CCILASER is headquartered in Jinan City, China. It is a world-renowned laser equipment company and a high tech enterprises integrating R&D, production and sales.

We are adhering to the tenet of "Quality first, customer first" and continues to grow. Main products include fiber laser cutting machine, plasma cutting machine, laser marking machine, laser engraving machine, laser welding machine and laser cleaning machine and etc.

Our company has passed ISO and CE international quality management system certificates, and has obtained FDA certification for the US market. We have our independent export rights.Machines are exported to more than 50 countries and regions.

Wish cooperating with you to create a better future!

8. FAQ

A. Question: What kind of our company is CCILASER?

Re: CCI is laser marking machines, laser welding machines, laser marking machines manufacturing expert since year 2002.

B. Question: How is LW-3-1500 automatic three axis fiber laser welding machine for stainless steel guarantee?

Re: b1.Warrenty period is 24 months after BL time;

b2.12 hours technical support feedback;

b3. Own machining factory, which can control the spare parts quality at high quality;

b4. Own accessories warehouse and user can enjoy the agent price.

C.Question: How is delivery time?

Re: We can delivery the machines within 7 days if we have the machines in stock.

The common machine fabricating time is 15-25 days and CNC machine fabricating time is about 25-50 days.If you have customized products, the delivery time will be given after confirmation.

D. Question: How is payment?

Re: 50% of amount as deposit and the balance should be paid by T/T or LC at sight before seller delivery the machines to loading port.

E.Question: How is our package?

Re: Wooden Pallet/ Wooden Case. In order to ensure high quality products precision, the perfect package is necessary.

F. Question: Why is price higher than other supplier?

Re: f1. We have our own machining factory and the high quality technical quality is our aim;

f2. All the electric parts and pneumatic parts are high quality. Most of them are imported from european and american market;

f3. Most of fabricating worker has more than 10 years working time. Their fabricating work is professional and salary is higher;

f4. Our warrenty period is 36 months after BL time. It can support the new comer client going well in the beginning time.

9. Customer Care

To be continued..

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23