Semi-Auto Pet Plastic Bottle Blowing Machine/Plastic Machine Plastic Bottle Making Machine ...

Zhejiang Ruizhao Technology Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. SKY-12 Bottle Volume 1gallon, 3gallon, 4gallon, 5gallon Speed 50bph to 100bph PLC Simens(Germany) Blow Moulding Type Stretch Blow Moulding Bottle Mold Stainless Steel Auxiliary Equipment Compressed Air, Air Dryer and Filter, Air Tank Mold Cavity 1cavity Certificate Ce ISO SGS Driven Type Pneumatic Color Customized Transport Package Non-Fumigation Plywood Specification customized Trademark Sky Machine Origin China HS Code 84223010 Production Capacity 10set/MonthProduct Description

SKY-12 Semiautomatic bottle blow molding machine( For 3-6gallon )Specification:

HY-Y blow molding machine is especially used to produce 3 gallon and 5 gallon bottles and is widely used to produce any shape of plastic from PET with neck finishes from 15mm-200mm.

Perfect function with economic investment.

Small size and compact construction with no space waste.

Easy to operate and maintain ,operation by one person.

Saving power and uneasy to worn out ,Adopting new double crank four bars to lock mould, the cross fixed. Providing high pressure blowing system.

We can provide performs and various bottle& cap molds for 5 gallon and 3gallon bottles to meet customer's requirements.

Semiautomatic Bottle Blower Model List

| Model | Bottle Volume | Theoretical Output | Blower(L*W*H) | Blower/Weight | Heater(L*W*H) | Heater/Weight | Power |

| SKY-12 | 10L-25L | 90-180pcs/h | 218*77*196cm | 1000kg | 237*68*135cm | 380kg | 40kw |

| SKY-8Y | 0.01L-2L | 1200-1600pcs/h | 160*60*161cm | 500kg | 187*63*145cm | 250kg | 17.5kw |

| SKY-SA4 | 0.01L-2.5L | 2000pcs/h | 190*88*180cm | 1000kg | 190*66*160cm | 380kg | 18kw |

| SKY-5L | 0.01L-5L | 300-800pcs/h | 175*67*186cm | 600kg | 187*63*145cm | 250kg | 17.5kw |

| SKY-10L | 5L-10L | 300-500pcs/h | 193*72*183cm | 800kg | 187*63*145cm | 250kg | 17.5kw |

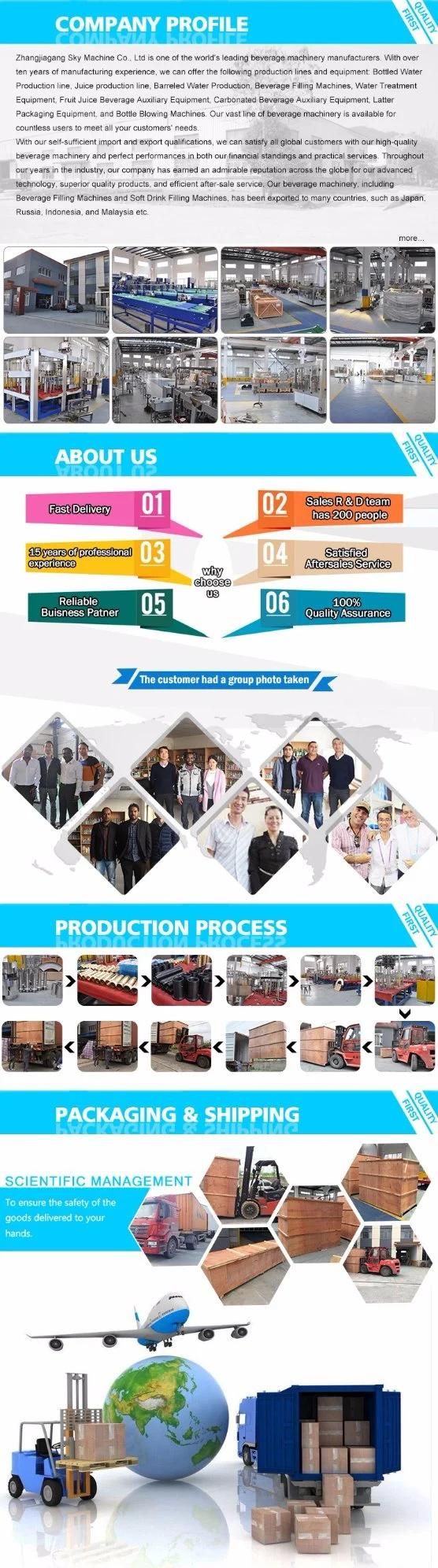

About us:

1. A: Are you factory?How many workers do you have?

B: Yes,we are factory. our factory is located in zhangjiagang near from shanghai. We have about 50 workers in our factory.

2. A: What about after sale service?

B: 12months of electrical part and 18months of mechanical part after machine installed and running normally.

3. A: What about installation?

B: Our engineer can be sent to your country. but customer should pay the air tickets and 100usd as salary per person per day. besides, customer should arrange the accommodation for them during the trip.

4. A: What do we do if we encounter problem about the machine ?

B: Show us the picture or video of the problem. If the problem is from small machine, we will send you solution by video. If the problem is from large machine, our engineer will go to your factory (customer will pay the fee during the trip).

5. A: How can you control the quality and delivery?

B: All our machines will be tested before packaging. wooden packaing is strong and safety for long delivery .

Contact :

Gloria Liu

Export Manager

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23