Belling Machine/Socketing Machine/Pipe End Socket Making Machine for PP Pipe

Poyang Tianli Diamond Tools Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. US110 Condition New Size 50-110mm Transport Package Standard Exporting Package Specification 50-110mm Trademark YUSHENG Origin Jiangsu, China HS Code 8477800000 Production Capacity 10sets/MonthProduct Description

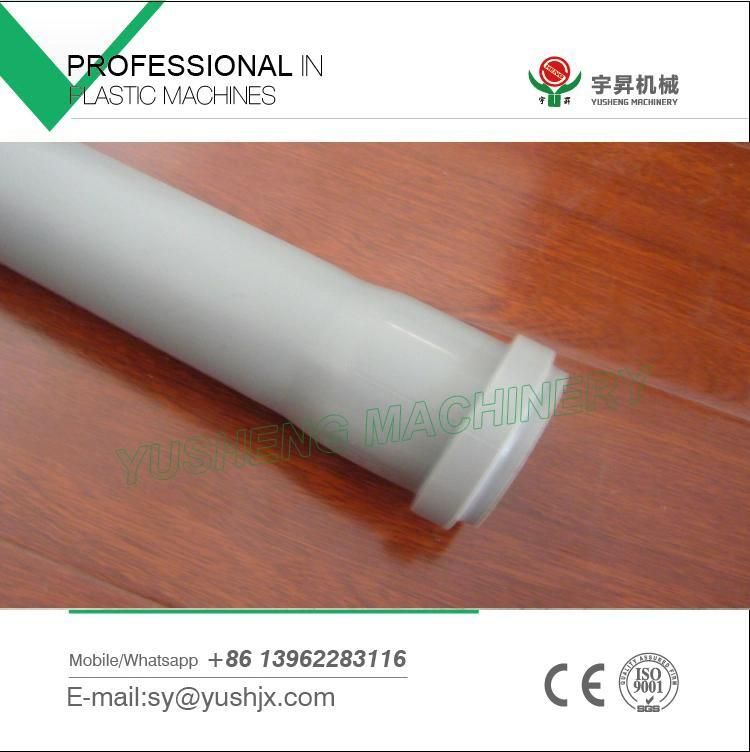

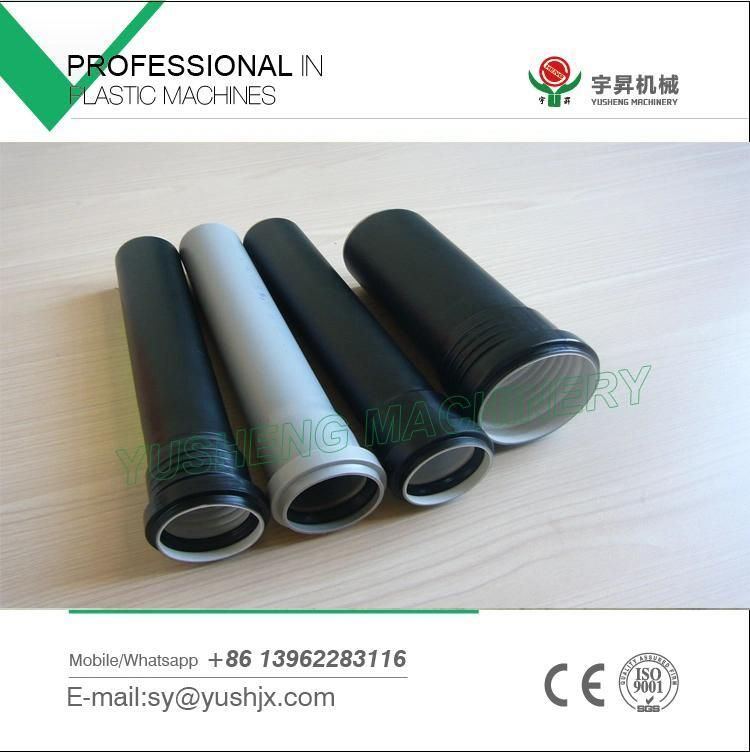

Belling Machine/Socketing Machine/Pipe End Socket Making Machine for PP Pipe1.The PVC Pipe Semi-Automatic Belling Machine is suitable for making socket for PVC pipes semi-automatically.

2.The machine adopts the same calibration method with the full automatic belling machine.

3.The pipe are supported by simple frame and moved moved by hand.

4.Move pipe manully. Heating and socket automatic

5. solvent cement & rubber ring

| Pipe range(OD) | Φ50-110mm |

| Pipe length | 3-6m |

| Socket type | U type(solvent) or R type or rectangle type |

| Socket method | U type: die tool insert R type: die tool expand |

| Cooling method | water cooling |

| Require cooling water pressure | 0.2~0.3Mpa |

| Quantity of heating oven | 1 |

| Heating method | Electric heating, by stainless steel heating rods |

| Heating power | 9kw |

| Total Power | 12kw |

| highest temperature in heater | 280ºC |

| Air pressure | 0.4~0.6Mpa |

| Center height | 1000mm±50mm (or according to extruder) |

| Machine set weight | About 1.2T |

| Require oil label | 46# wear resistance hydraulic oil |

AFTER-SALE SEVICE&TECHOLIGY SUPPORT:

INSTALLING FOR FREE

1. Warranty time: One year guaranteed for quality, product whole life service any damage except the wrong operation during warranty. Period is repaired freely, But the travel and hotel expenses should be count on buyer.

2. Commissioning services: The product's installation and commissioning at the demand side, our engineers will not leave there until get your agreement.

3. Traning Services: Our engineers will train your staff in your factory or video to operate it during the period of installation and commissioning, and they will not leave there until your staff can operate it properly and normally.

4. Manintenance Services: Any malfunction happened, Once you inquiry us, We will reply you within 24 hours.

5. The File: The manual specification, report of the material which used to the equipment and other documents video related to GMP authentication information will be provided by us.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23