Plastic Recycling Machine, Pet Plastic Recycling Machine

Zhongshan Tianxin Craft Gift Products Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. Pet Plastic Recycling Machine Computerized Non-Computerized Certification CE, SGS Name Pet Recycling Machine Color Green Motor Siemens Inverter ABB Handle Waste Plastic Bottle Core Part Plastic Crusher Drying Centrifuge Dewatering City Zhangjiagang Hot Washing Mothod Steam Clean Medicament Cuastic Soda Machine Material Stainless Steel 304 Blade Material SKD11 Temperature Control Omron Contactor Schneide Frictiong Washer High Speed Type Transport Package Film Sea Packing Specification WD-1000 Trademark WEDO Origin China HS Code 8477800000 Production Capacity 10 Sets Per YearProduct Description

Plastic Recycling Machine, Pet Plastic Recycling MachineDescription of waste drining water bottles, post-consumer PET plastic bottle recycling machine:

This plastic recycling machine is to crushing washing recycling the waste plastic PET bottles. This PET plastic recycling machine is consist of label remover, sortor, crusher, cold washer, hot washer, dewatering, packing system. It can get the clean PET flakes from PE PP cap, oil, PVC label, then use the PET flakes again, to avoid plastic pollution.

This PET plastic recycling machine can easily wash and recycle waste PET bottles. Waste and dirty PET bottles can be disposal step by step in this PET plastic recycling machine. It is special for recycling PET bottles. We equiped drying system at the end of the washing line so that completely dry flakes can be collected and packed directly after been washed.

The whole PET plastic recycling machine can designed based on how dirty the PET bottles are, and make sure of the quality of the final products.

Coordinating the production line with follow processing work (PET pelletizing machine), and it will make waste and dirty PET bottles to be the PET pellets material, and can to producing new PET bottles.

The whole waste drining water bottles, post-consumer PET plastic bottle recycling machine line includes(customizable):

Metal Chain Convery→De-Baler(Baler Opener) →Belt Conveyor→Tromel→Belt Conveyor→Label Remover→Sorting Table→Metal Detactor→Belt Conveyor→Crusher→Screw Loader→Floating Washer→Friction Waser→Hot Washer→Screw Loader→Friction Washer→Floating Washer→Dewatering Machine→Zig-Zag Separater→Silo

Photos of waste drining water bottles, post-consumer PET plastic bottle recycling machine:

Metal chain coveyor for Pet Plastic Drink Bottle Recycling Machine

debaler machine for Pet Plastic Drink Bottle Recycling Machine

babel remover of Pet Plastic Drink Bottle Recycling Machine

Crusher/granulator/grinder of Pet Plastic Drink Bottle Recycling Machine

Dewatering machine of Pet Plastic Drink Bottle Recycling Machine

Hot washing tank of the Pet Plastic Drink Bottle Recycling Machine

The fuction of some main parts in waste drining water bottles, post-consumer PET plastic bottle recycling machine:

- Belt Conveyor: The materials go into the crusher by the crawler belt, which is move by inside scroll wheel.

- Label Remover: Remove the label from the bottles.

- Manual Sorting Belt: If the label still in the bottle, worker can remove the label by hand. In addition, can separate the different color by hand.

- Crusher/Grinder: Crushing the material into small size.

- Screw Loader: to transform the material to next step.

- Hot Washer: To washing off the dirty, like oil, sand, in hot washer need use the detergent, then can get very clean PET flakes.

- High-speed Friction Washer: Through the high speed on the shaft of the vane flap and spray water to the common function of good cleaning effect.

- Floating Washer: It used in cleaning pet flakes, make the flakes cleaner and whiter. Also is the necessary equipment of the bottle and bottle cap.

- Dewatering: Rejection the water from the flakes, moisture content is less than 2%.

Technical data of waste drining water bottles, post-consumer PET plastic bottle recycling machine

| Input capacity | 1000kg/h | 1500 kg/h | 2000 kg/h |

| Workshop(M*M*M) | 60 (L)×10(W)×6(H) | 70(L)×10(W)×6(H) | 90(L)×18(W)×6(H) |

| Labor | 8Persons | 10 Persons | 14 Persons |

| Installation power | 240KW | 307KW | 420KW |

| Water needed: | 4~5Ton/h | 6~8Ton/h | 8~10 Ton/h |

| Final flakes | Moisture: max 1.5% Bulk density: 0.3G/CM3 Particle size: 10-16mm Metal content: max.20ppm Floatable contamination: less than 200ppm Total impurity: 320ppm | Moisture: max 1.5% Bulk density: 0.3G/CM3 Particle size: 10-16mm Metal content: max. 20ppm Floatable contamination: less than 200ppm Total impurity: 320ppm | Moisture: max 1.5% Bulk density: 0.3G/CM3 Particle size: 10-16mm Metal content: Max. 20ppm Floatable contamination: less than 200ppm Total impurity: 320ppm |

After this waste drining water bottles, post-consumer PET plastic bottle recycling machine, we also supply the following production lines of PET plastic pelletizing machine, that to make the PET flake become the PET pellets.

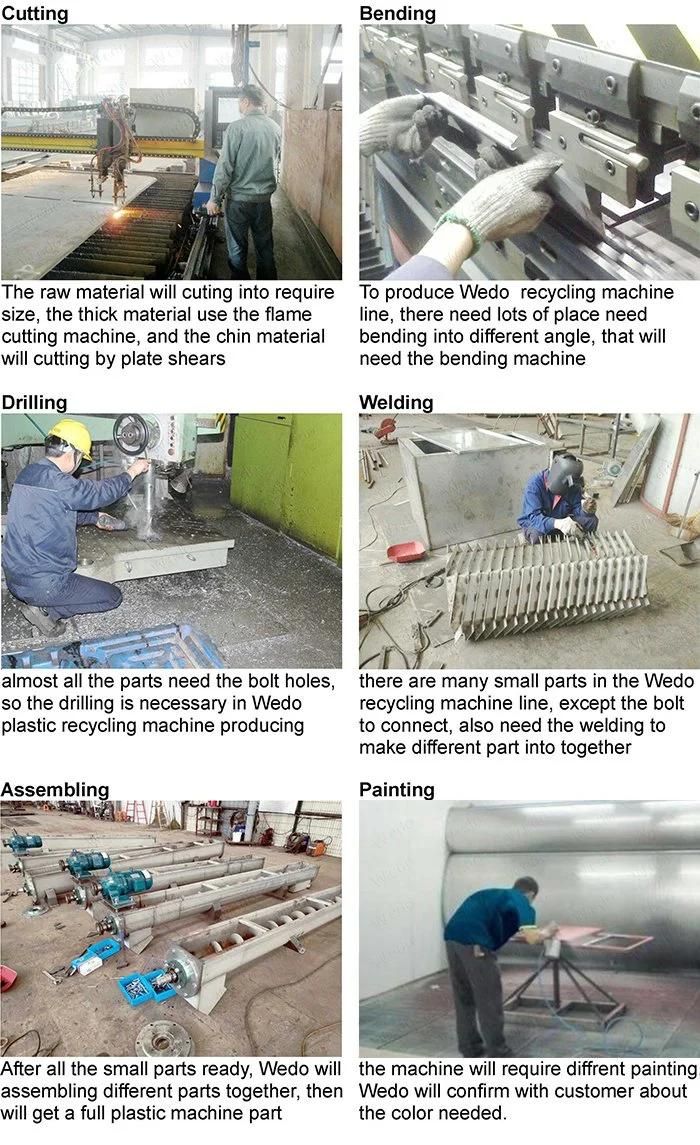

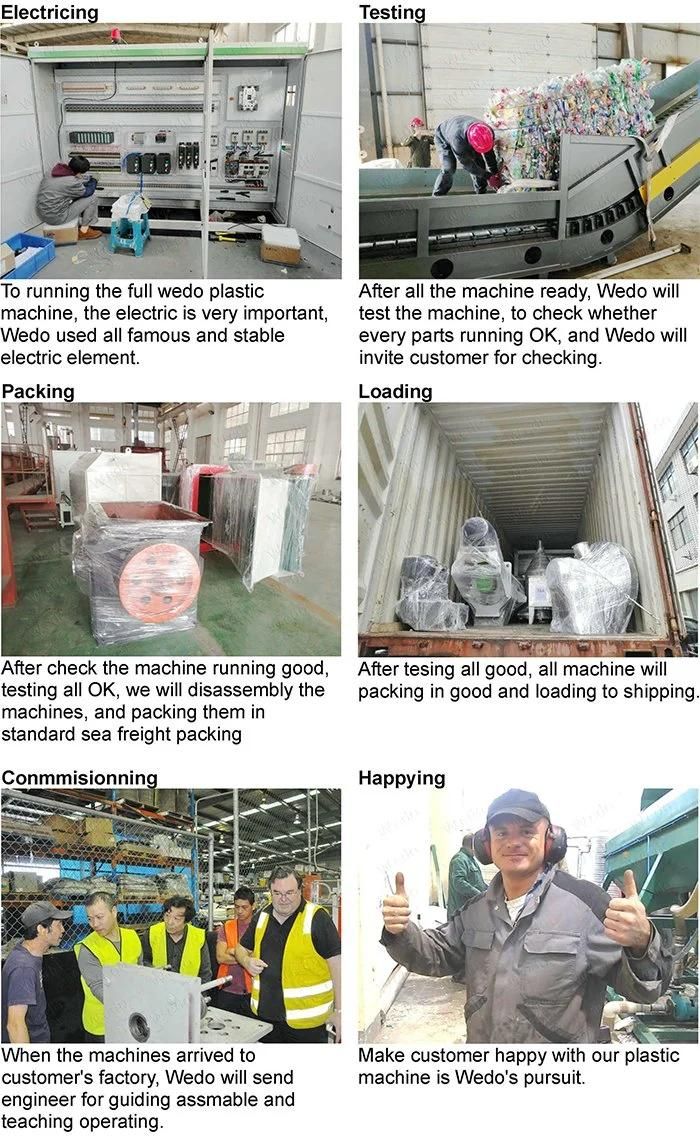

Wedo Produce steps:

Wedo have a fully step for the Pet Plastic Drink Bottle Recycling Machine producing before packing and shipping, this ensure the plastic recycling machine will delivery in good quality, and custerm will get good machine.

Wedo service:

We do best service for you in Pet Plastic Drink Bottle Recycling Machine

After this Pet Plastic Drink Bottle Recycling Machine, our company also supply the following recycling lines of PET plastic pelletizing machine, that can make the PP PE film into PP PE pellets.

Any further about the Plastic Recycling Machine, Pet Plastic Recycling Machine, please contact us timely we will give your professional fully support.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23