Twin Screw Food Extruder Machines Tortilla Machine Production Line

Qingdao Baigu Plastic Products Co., Ltd. / 2022-07-05

- Certification:CE, MET, CSA, UL, SA8000, ISO9001

- Power Source:Electric

- Process:Bulking Machine

- Automatic Grade:Automatic

- Application:Puffed Snacks

- Customized:Customized

=== Base Info ===

- Model NO.:TSE65,70

- Material:304,201 Stainless Steel

- Capacity:150kg,H, 250kg,H

- Model:Doule Screw

- Operator:1-2 Workers

- Raw Material:Corn Powder, Corn Starch

- Voltage:220,380,415V etc.

- Type:Full Automatic

- Package:Wooden Case

- Usage:Snacks Factory

- Function:Multifunctional

- Transport Package:Wooden Cases

- Specification:20*2.0*3.0m

- Trademark:Shengrun

- Origin:Jinan City, Shandong Province, China

- HS Code:8438800000

- Production Capacity:300kg,H, 500kg,H

=== Description ===

Basic Info.

Model NO. TSE65/70 Material 304/201 Stainless Steel Capacity 150kg/H, 250kg/H Model Doule Screw Operator 1-2 Workers Raw Material Corn Powder, Corn Starch Voltage 220/380/415V etc. Type Full Automatic Package Wooden Case Usage Snacks Factory Function Multifunctional Transport Package Wooden Cases Specification 20*2.0*3.0m Trademark Shengrun Origin Jinan City, Shandong Province, China HS Code 8438800000 Production Capacity 300kg/H, 500kg/HProduct Description

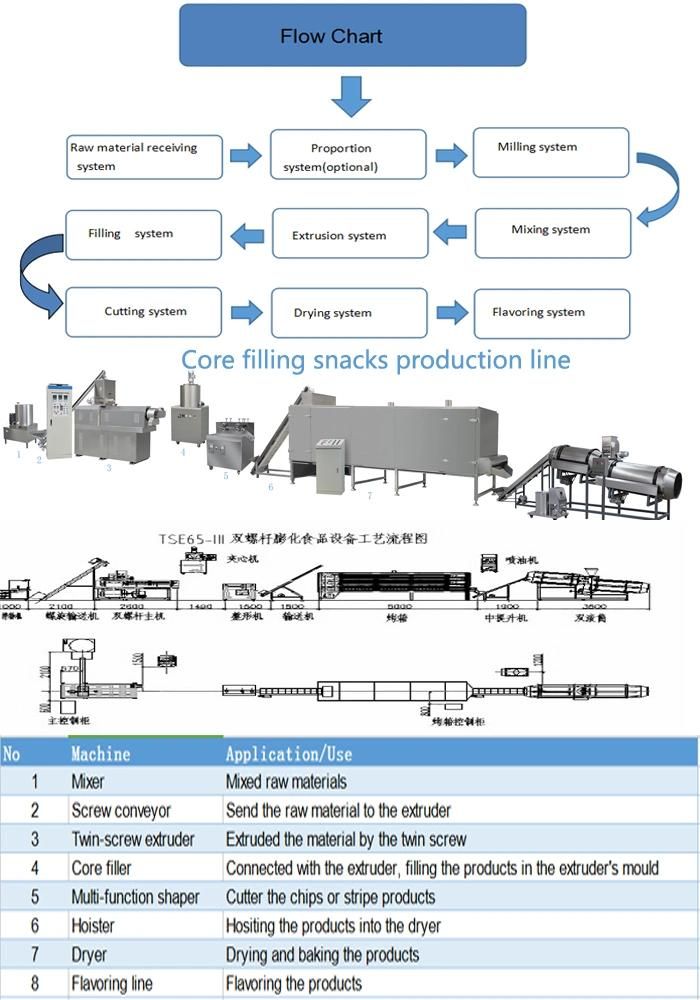

1. Introduction of production lineCore filling snacks production line includes mixing, extruding, filling, cutting, conveying, drying, flavoring, cooling system. It's full automatic. According to different shape products, it need different cutter. The shapes includes pillow shape core filling snacks, corn curls, corn sticks, coco pops, stars,flower and etc. The core material is anhydrous cream, chocolate. It can take corn, rice, wheat, oat, rye and other cereals powder as raw materials to produce extruded snacks, with crispy taste and lively shape. And it's designed according to market demand.

Process flow: mixing--extruding & puffing-Core filling-Cutting-Conveying --Drying--flavoring--Cooling(Packing)

Equipment flow: Mixer--Screw conveyor - Extruder-Core filling machine-Cutter-Hoister-Dryer-Hoisting and flavoring line--Cooling machine(Packing machine)

Our TSE75/85 core filling snacks production line show

2. Features of core filling snacks production line

A. Alloy (38CrMoAL) screw made by nitriding process, high strength and wear-resting.B. Gearbox with automatic lubrication function, extending gear life. C. Self-cleaning ability, no need to discharge or clean the barrel and screw when roasting or replacing of materials. D. Production line is full automatic, only need 1-2 persons to operate.

3. Technical parameter

| Model | TSE75 | TSE85 |

| Installed power | 190kw | 180kw |

| Actual consumption power | 140kw | 150kw |

| Capacity | 300-400kg/h | 300-500kg/h |

| Dimension | 25000×1500×2200mm | 30000×1500×2600mm |

4.Main machines description

5. Samples Show

The basic formula of sample

corn meal, rice flour, wheat flour , corn starch, wheat bran, sugar, palm oil, cocoa powder, cream, chocolate, jam, peanut butter, vitamins, minerals, food color etc.

Humidity: the moisture is no more than 10%.

Shapes: pillow, finger, round bar, square bar, hollow tube or customrized. (Change moulds to make all shapes unfilled snack.)

Sizes: (1) diameter: up to 25mm (2) length: user-defined.

6. Our machines details show

The show of our dryer

7. Company Information

Shandong Shengrun Machinery Co. Ltd. is an expert of double/twin-screw extruders and single screw food extruders with more than 10 years experience. "Shengun Machinery Company" is located in the beautiful "Springs City" Jinan, China, covers an area of more than 10,000 square meters, construction area of over 8,000 square meters, of which more than 6,000 square meters of modern assembly plant.

With the professional R&D team, Production team, Sales team, and After service teams, we can provide advanced food extrusion machines and food extrusion technology for customers. We have enough sales and service experience which can provide the most suitable solutions according to customers' specific demands and budget.

Adhering to the enterprise philosophy of "Quality casting success, Service creating the future", our company has won the praise from more and more domestic and abroad users.

Technology without borders, Service is endless.

Let's work together, we will do create something better!

8. Packing&Shipping

1. Packing machines into wooden cases;

2. Let trucks take containers to our factory for safely loading;

3. Sending to port for boarding and transportation.

4. We also can send machines by air and train.

9. FAQ

A. Is configuration(allocation) fixed standard?

Answer: No, it is flexible, we will equip machines based on your requirement;

B. Can I come to check your company(Jinan Shengrun Machinery Co., Ltd.)?

Answer: Welcome to visit us! We will show our machines in our factory;

C. Do you have shipping agent for delivery?

Answer: Yes, we have reliable shipping agent. They can offer a good freight and take care the process very well;

D. Can you test our formulation with your extruder?

Answer: As long as you trust on us, we can test your basic formula, then you can see the outcome and place order without any hesitation;

E. Why the price in the web is a range?

Answer: As we have many models, and the production lines' configuration are various. So we will equip machines based on customers' specific requirement. So, the price range is for reference.

Don't hesitate to contact us.

If you have any other question, please send me the inquiry as soon as possible, waiting for you my friend. Thanks

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23