Tct Circular Saw Blade/Cutting Disc/Carbide Saw Blade for Aluminum Cutting

Shijiazhuang Fuxie Trading Co., Ltd. / 2022-06-27

- Blade Type:Brazed

- Manufacturing Process:Brazed

- Application:Dry and Wet Cutting

- Steel Blank:65 Mn

- Transport Package:Carton and Pallet

- Specification:From 100mm to 800mm are all available

=== Base Info ===

- Model NO.:Brazed

- Trademark:PROTEC

- Origin:China

- HS Code:82023910

- Production Capacity:100000

=== Description ===

Basic Info.

Model NO. Brazed Trademark PROTEC Origin China HS Code 82023910 Production Capacity 100000Product Description

Basic info| Model No. | PT- PDTCTSBA | Application: | For cutting aluminum and other non-ferrous profiles with very thin wall thickness,copper, brass, bronze and even some plastics. |

| Samples: | Free samples when it is stock | Size: | From 100mm to 800mm are all available |

| Arbor: | 30mm, 25.4mm, 22.23mm and as required | Delivery Time: | Based on the Quantity |

| Price Term: | EXW, FOB, CIF, CNF, DDP, DDU and Etc | Payment Term: | TT, LC, Western Union, PAYPAL, CREDIT CARD |

| Color: | Black, Plain, Silver, Blue and as required | Quality: | All have to pass 3 times QC inspection |

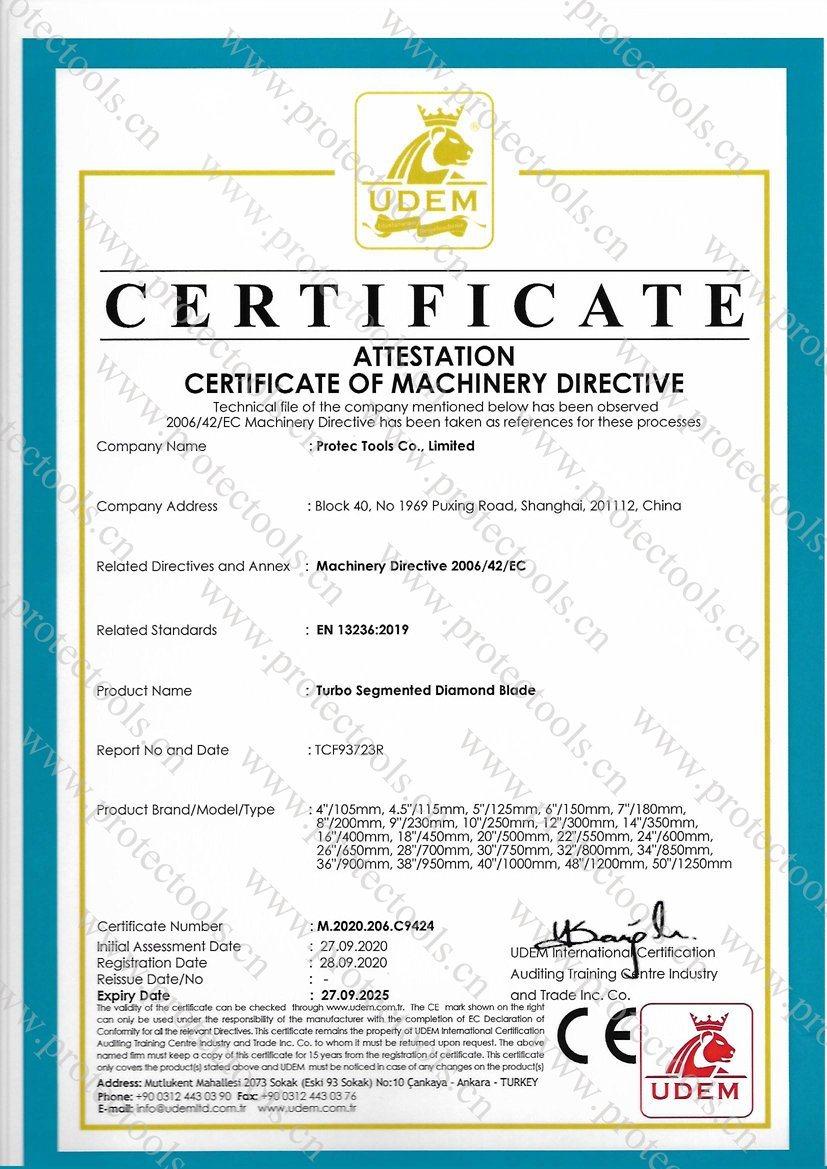

| Certificate: | CE EN13236 | Test report: | Have |

| Transport Package: | Double Corrugated Carton and pallet | Service: | Custom-made Service |

| Sample order: | Available | Trademark: | Protec |

| Origin: | China | HS CODE: | 82023910 |

Product Description

| Diameter | Arbor hole | Teeth Type | Segment Thickness | Segment Quantity |

| 4"/105mm | 30mm/22 and as required | ATB/TCG | 1.8/2.0/1.4/3.2/2.2mm and as required | 20/32/40 and as required |

| 4.5"/115mm | 30mm/22 and as required | ATB/TCG | 1.8/2.0/1.4/3.2/2.2mm and as required | 20/32/40 and as required |

| 5"/125mm | 30mm/22 and as required | ATB/TCG | 2.0/1.4/3.2/2.2mm and as required | 20/32/40 and as required |

| 6"/150mm | 30mm/22 and as required | ATB/TCG | 2.0/1.4/3.2/2.2mm and as required | 20/32/40 and as required |

| 7"/180mm | 30mm/22 and as required | ATB/TCG | 3.2/2.2mm and as required | 20/32/40 and as required |

| 8"/200mm | 30mm/22 and as required | ATB/TCG | 3.2/2.2mm and as required | 20/32/40/50 and as required |

| 9"/230mm | 30mm/22 and as required | ATB/TCG | 3.2/2.2mm and as required | 20/32/40/50 and as required |

| 10"/250mm | 30mm/22 and as required | ATB/TCG | 3.2/2.2mm and as required | 20/32/40/50 and as required |

| 12"/300mm | 30mm/22 and as required | ATB/TCG | 3.2/2.2mm and as required | 20/32/40/50/84 and as required |

| 14"/350mm | 30mm/22 and as required | ATB/TCG | 3.5/2.5mm and as required | 20/32/40/50/84 and as required |

| 16"/400mm | 30mm/22 and as required | ATB/TCG | 3.5/2.5mm and as required | 50/84/100 /120and as required |

| 18"/450mm | 30mm/22 and as required | ATB/TCG | 3.5/2.5mm and as required | 50/84/100/120 and as required |

| 20"/500mm | 30mm/22 and as required | ATB/TCG | 3.5/2.5mm and as required | 100/120/150/160/200 and as required |

| 24"/600mm | 30mm/22 and as required | ATB/TCG | 3.5/2.5mm and as required | 100/120/150/160/200 and as required |

| 30"/760mm | 30mm/22 and as required | ATB/TCG | 3.5/2.5mm and as required | 100/120/150/160/200 and as required |

| 32"/800mm | 30mm/22 and as required | ATB/TCG | 3.5/2.5mm and as required | 100/120/150/160/200 and as required |

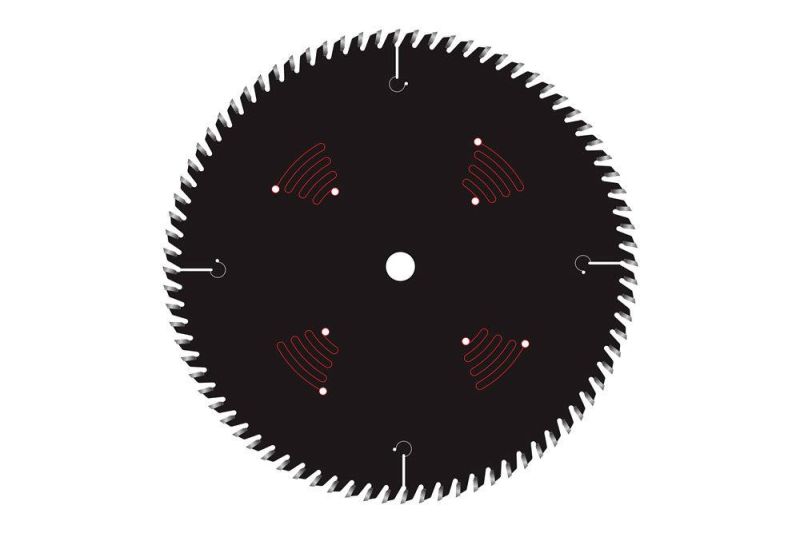

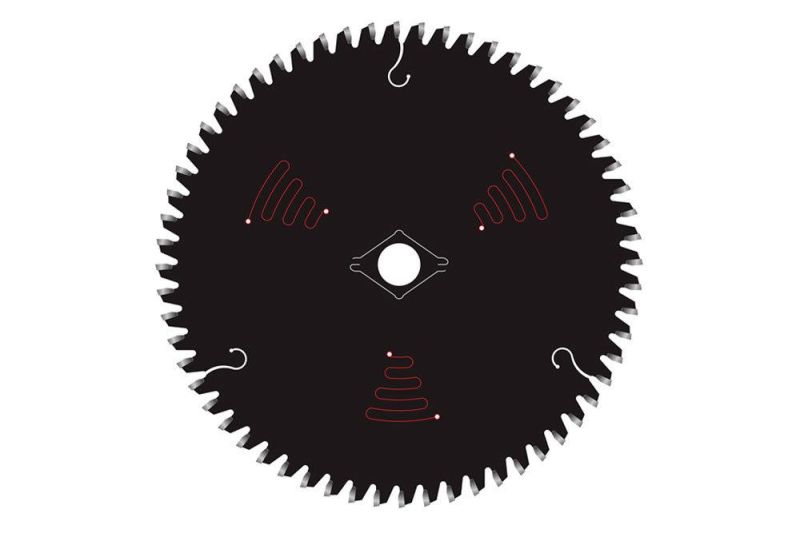

TCT SAW BLADE/CARBIDE SAW BLADE/CIRCULAR SAW BLADE FOR ALUMINUM

Product Description:

Our TCT circular saw blades are designed for cutting aluminum and other non-ferrous profiles with very thin wall thickness. Excellent also for cutting plain aluminum or non-ferrous bars. the work piece must be properly clamped during cutting.

Features:

1. The specially formulated carbide lasts longer and leaves clean, burr free cuts in all types of non ferrous metals such as aluminum, copper, brass, bronze and even some plastics.

2.Feature copper plugged expansion slots and heat vents for cooler operation for reduced noise and vibration

3. The circular saw blade thin kerf for fast and smooth cutting action. Thin kerf and anti-stick rim for smooth, accurate cuts balanced plate reduces vibration

4. Ultra sharp, hard titanium carbide. Triple Chip Tooth Grind.

Application: For cutting aluminum and other non-ferrous profiles with very thin wall thickness, copper, brass, bronze and even some plastics.

Product show

Manufacturing process

Inspection

Cutting test

Why choose us

Company profile

Protec Tools Co.,Limited ,was established in 2006. As a professional and experiened diamond saw blade and drilling tools manufacturer , To give our customers best quality tools , make them work easier , more efficient and lower cost is what we always focused on . By continuous research, successful and unsuccessful experience, thousands of testing, PROTEC has developed best bonding for most of the building materials from different areas all over the world. In order to keep our products at a high level , we take the most advanced equipments in this industry,such as the automatic laser welding machine, automatic segment press and sintering machine etc.Our products are manufacted coordinate to CE/EN13236. All of these efforts leading a significant grows every year. All our customers will find it is happy to work with PROTEC for the satisfying products and service .Our products are exported to more than 30 countries all over the world and we are the OEM supplier of some world wide famous brands. Looking forward to work for you.

We export to more than 30 countries all over the world

Work shop

Fairs and customer meeting

CE CERTIFICATE

Our diamond saw blades are compliant to CE/EN13236 .

Our service

a) Good after-sale service, all questions will be replied within 12 hours.

b) Customized design is available. ODM&OEM are welcomed.

c) We can provide free sample.

d) Convenient transportation and fast delivery, all available shipping ways could be applied, by express, air or sea.

e) High quality and most competitive price.

f) Advanced produce and inspecting equipments.

FAQ:

1. Can I order a small list?

---Yes. Of course you can.

2. What price do you offer?

---FOB, CIF, CNF, DDU, DDP and other ways according to your request.

3. How can we ship to you?

---By sea, By air, By express, By train and other transport ways according to your request.

4. What is the quality of your products guarantee?

---We have passed CE certification.

5.Do you have after-sales service?

---Certainly, you can contact us at any time.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23