PP PE Film Recycling Line Single Screw Extruder

ShunDe Jiatian Hard Tool Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

(mm)

(kw)

(kg/h)

Raw material:

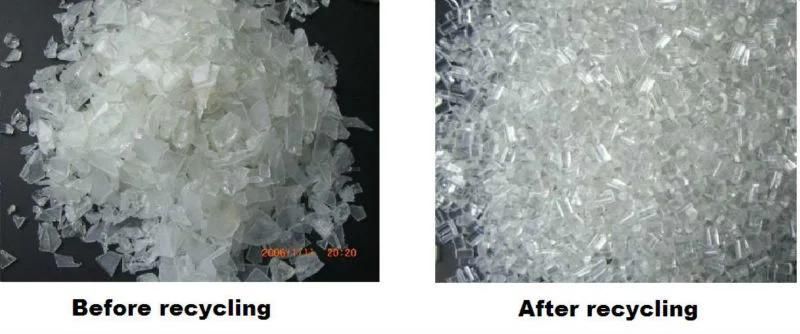

If your material are like these, and you do not want to spend too much on the recycle machine. our HMS single screw two stage extrder is your best choice!

Application

The new granules from our machine can be used in manufacture machine parts, water pipes, bags, buckets, toys and other living utensils.

Our advantages:

non-stop screen changer die head: better for filter impurities. It saves you huge cost on washing the waste plastics.

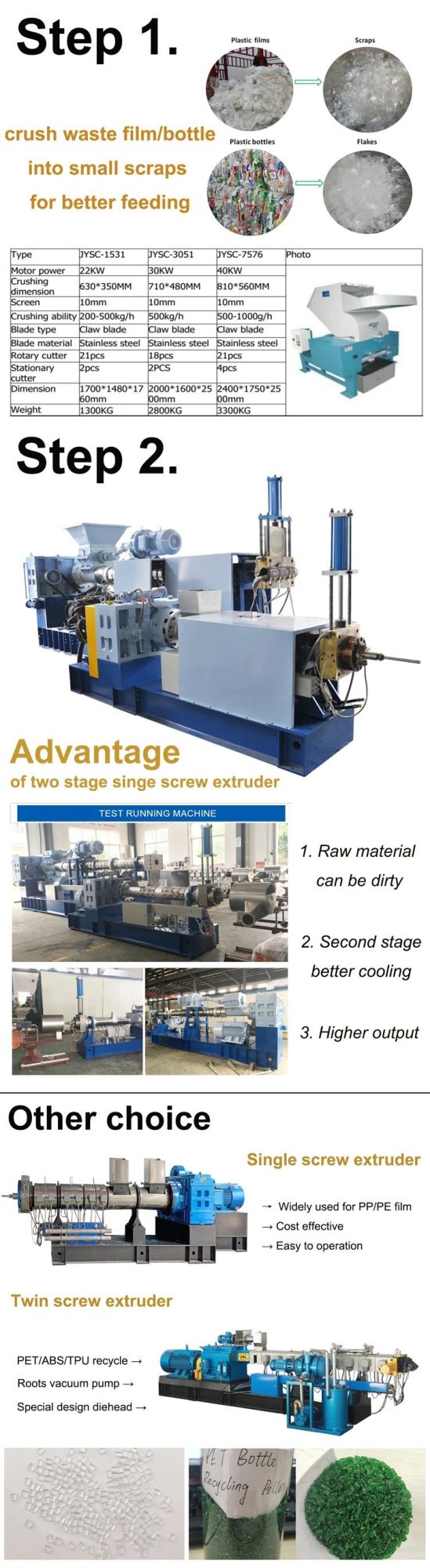

Auxiliary machines you may need:

The line with belt conveyer ,crusher ,extruder, auxiliary equipment. The line with characteristics of high output,low energy dissipation,labor-force saving,and high quality pellets,is an ideal equipment for film recycling and granulating line.

Work Line of the recycling granulating Machine :

The first step: washing and crushing line

The second step: Granules pelletizing line

Features of water cooling strand pelletizing system

Water cooling strand pelletizing system could be applied to most polymer materials processing and application, the entire system is simple and practical, more convenient operation and maintenance. Main components typically include: extrusion template, cooling water tank, drying machine, cooling granulator, vibrating screen and follow-up silo packing system.

Nanjing HaiSi Extrusion Equipment Co., Ltd is a High-Tech company, which is composed of well-experienced team in R&D, manufacturing technique, sales service and basing on extruder industry for many years. Our company is a professional manufacture of high quality pelletizing extruders for coloring/ dyeing and master batch production, as well as plastic modification and compounding, plastic recycling. Innovation machines are built as per the concept of durability, high efficiency and economical power consumption.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23