CO2 Laser Engraving Machine S960-1610

Luoyang Beeway Group / 2022-06-23

- After-sales Service:Always

- Warranty:One Year

- Application:Automotive Industry, Woodwork Industry, Advertising Industry

- Cooling System:Water Cooling

- Technical Class:Vector Cutting

- Applicable Material:Nonmetal

=== Base Info ===

- Model NO.:S960-1610

- Structure Type:Gantry Type

- Laser Classification:Gaseous Laser

- Laser Technology:Laser Control Fault Cutting

- Transport Package:Wood

- Trademark:REFINE

- Origin:Hefei

=== Description ===

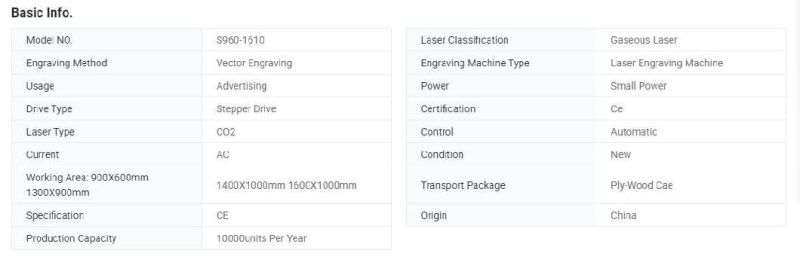

Basic Info.

Model NO. S960-1610 Structure Type Gantry Type Laser Classification Gaseous Laser Laser Technology Laser Control Fault Cutting Transport Package Wood Trademark REFINE Origin HefeiProduct Description

CO2 laser engraving machine S960-1610

Product Description

Technical ParametersModel: SF960/SF1390/SF1410/SF1610

Working Area: 900x600mm 1300x900mm 1400x1000mm 1600x1000mm

Laser Type: Sealed CO2 laser tube

Laser Power: 60W, 80W100W

Working table: Blade or honeycomb

Cooling Mode: Water cooling and protection system

Engraving Speed: 0-60, 000mm/min

Resolution Rate: ± 0.05mm

Minimum Character: Englishl x 1mm

Supported Graphic Formats: BMPHPGLPLTDSTAI

Controlling Software: DSP control system

Compatible Software: CorelDraw, AutoCAD, Photoshop

Driving System: Stepper

Dimesion: 1420*1020*1100mm

Gross Weight: 300kg

Working Voltage: AC 110-220V ± 10%, 50-60Hz

Working Tempetature: 0-45°C Working Humidity: 5-95%

Product Features

SF960 series machines adopt DSP digital controlling technology, self-design laser power supply, incorporate designed frameand structure to guarantee stable work. The newest software is matched to AutoCAD, corelDRAW CAD and all other graphics processing softwares for outputing original graphics. This series machines firstlyuse US8 port data interface which supports hot-plugging and momentary data transmission to realize high efficiency without accounting computer resource. The LCD controlling panel brings friendly computer-human interface and easy operation.

The most advanced DSP controlling technology development firstly in this field offers functions of successive, rapid and curved cutting. Optimization of shortest processing path to create high efficiency. Compensation of luminancedecrease is madeautomatically in the course of engraving to keep identical cutting in differentareas. Productionefficiencyisgreatly improved through using rapid controlling software for cutting and buffering function in high speed movement.

Professional accessories suitable for various processing such as aluminum alloy honecomb bottom board of different bore diameters made of aluminum alloy. Metal columns of different intervals and negative pressure adsorption device for soft materials can be provided according to customers' demands and materials. Which realizes design and processing on-the-spot.

The newest software is matched to AutoCAD, corelDRAW CAD and all other graphics processing softwares for outputting original graphics. Advanced color management supports any color and defines engraving sequence freely to realize one time or whole output.

It use USB port data interface with large mass storagedevice to provide high working speed and efficiency.

Applicable Industry

Applicable lndustries: Garment, leather, cloth toys, computer embroidery cutting, mould, crafts, bamboo andwood advertising and building decoration. Packaging and printing. Paper products, etc.

Applicable materials: Rubber, plastic, cloth, leather, woolens, crystal, organic, glass, jade, bamboo and wooden products, etc.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23