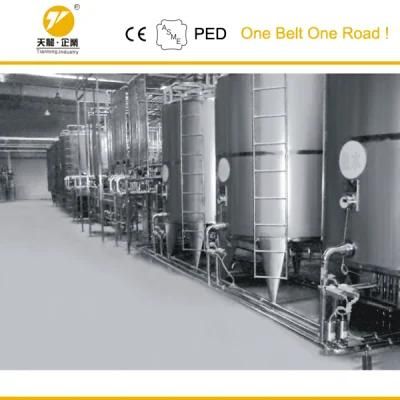

Movable Manual CIP Clean System

Auber Packaging Co., Ltd. / 2022-07-05

- Process:Cleaning

- Power Source:Electric

- Certification:ISO9001

- Automatic Grade:Manual

- Application:Milk, Yogurt, Cheese

- Customized:Customized

=== Base Info ===

- Model NO.:1T-10T

- Material:Ss316L

- Transport Package:Normal Export Package

- Specification:1T-10T

- Trademark:Tianlong

- Origin:Wenzhou, China

- Production Capacity:100sets Per Month

=== Description ===

Basic Info.

Model NO. 1T-10T Material Ss316L Transport Package Normal Export Package Specification 1T-10T Trademark Tianlong Origin Wenzhou, China Production Capacity 100sets Per MonthProduct Description

Operators start heating of cleaning liquids.When concentration of cleaning liquid is not up to the concentration of cleaning, operator will add thick acid liquids or thick alkali liquids to acid tanks or alkali tanks.During cleaning , CIP liquids are fed through pipes and valves by operators.Operators shall add water into tanks when they are in shortage of water.Advantages: medium capital investment on equipments and medium requirements on operators.After proper traning ,operator will be able to operate.

Disadvantages: little automatized,in a long time run , investment on humans' labor is high. Control on temperature of cleaning liquid is not precise.Manual adding of thick acid and thick alkali degrades safety in production,and producing efficiency is low .

For medium capital investment, it is a good choice for small manufacturers enterprises of dairy products and beverages.

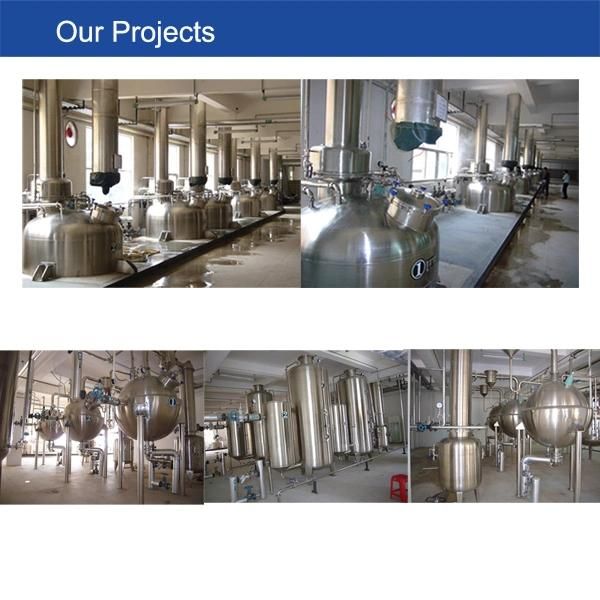

Note:1.Plate heating type: heat exchanging efficientcy of plate is high,which reduces steam consumption and cost.Coil-pipe heating type:heat-exchanging efficiency is lower than plate heating type.but its invested cost is less than plate heating type.(Can be attached with steam-through heating).

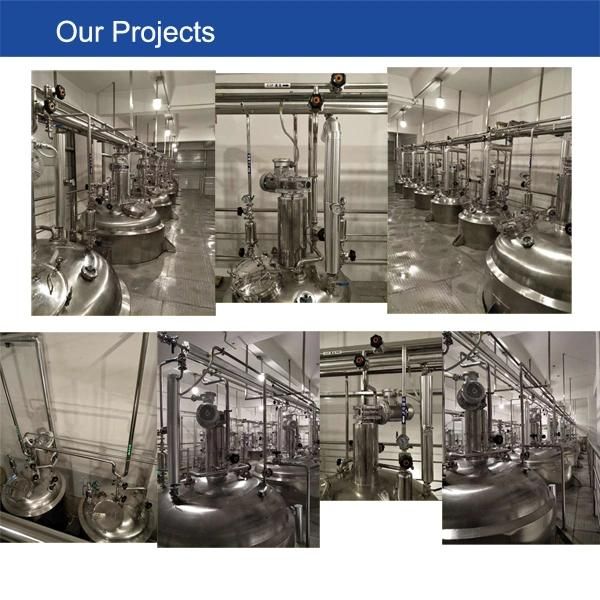

2.All specifications of joint type have systems of three basic types of tanks (including acid tank,alkali tank and hot water tank).All specifications of split type are of systems of three types,four types and five types of tanks.

Pls contact David :0086-15868559136

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23