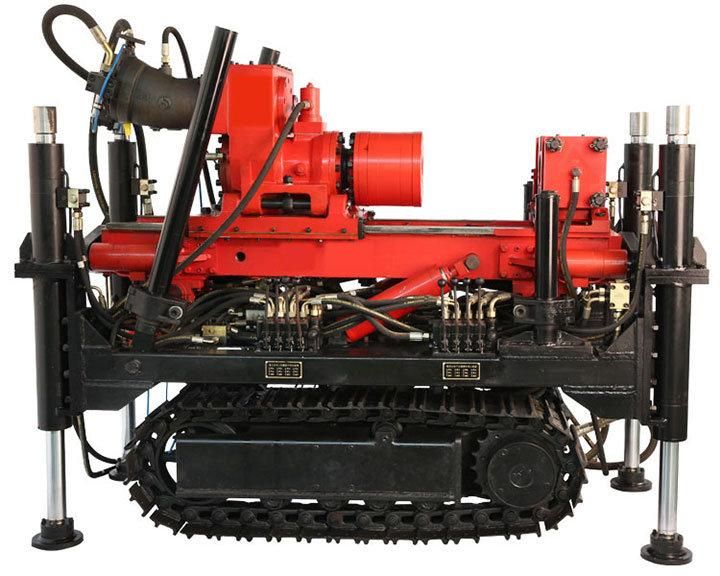

Mine Double Crawler Hydraulic System Drill Rig

Zhejiang Yunguang Machine Manufacturing Co., Ltd. / 2022-06-23

=== Base Info ===

=== Description ===

Basic Info.

Drill Pipe Diameter Φ73/Φ63.5 The Ability to Pull 160kn The Motor Power 55kw Borehole Inclination 0--±90° The Whole Machine Quality 5500 The Maximum Torque 4000n.M Pulling The Trip 600 Walking Speed 1.5km/H Maximum Climbing Ability 25° Name Drill Rig Transport Package Color Box Trademark XBT-TOOLS Origin Dezhou ChinaProduct Description

mine Double crawler hydraulic system Drill RigShandong xibit Precision Machinery Co., Ltd. is located in Pingyuan County, the hometown of machine tools in China. It is an earlier manufacturer of prestressed anchorage and machine tool accessories in China.

Product parameter description.

ZDY6000L crawler full hydraulic tunnel drilling rig for coal mine is a crawler self-propelled full hydraulic power head tunnel drilling rig with low transfer speed, large torque and suitable for large diameter and medium deep hole drilling. The drilling rig has the advantages of advanced technical performance, strong process adaptability, safe and reliable, and easy to move. It is mainly suitable for the construction of large diameter medium depth gas drainage and other engineering holes in coal mines.

Product structure of full hydraulic drilling rig

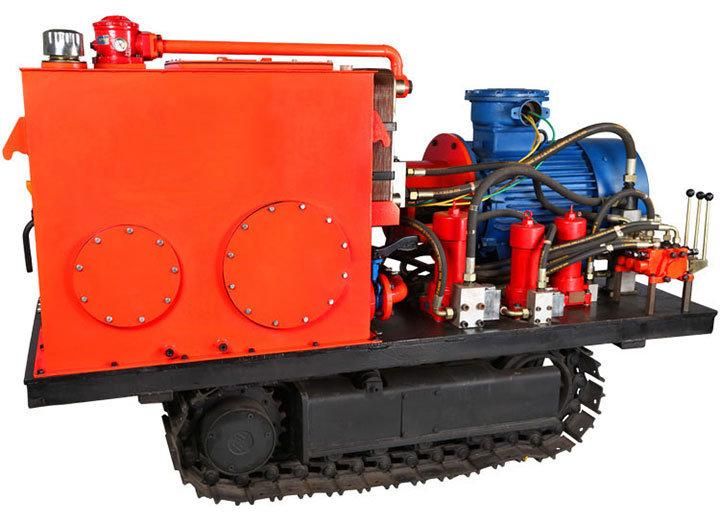

ZDY6000L tunnel drilling machine for coal mine adopts integral layout. The whole machine consists of four parts, i.e. main engine, pump station, console and crawler body. All parts are connected by flexible pipes. It is compact in structure and easy to move and transport. It is suitable for areas with poor transport conditions.

Features of full hydraulic drilling rig

1. The main engine, pump station and control console are arranged on the self-propelled crawler car body, which is convenient to move;

2. The combination of chuck and gripper can realize the mechanization of drilling tool screwing and unloading and reduce the labor intensity of workers. Multiple linkage functions are set on the drilling rig to improve the working efficiency;

3. The ability of feeding and pulling drilling tools is large, which improves the ability of drilling rig to deal with sticking accidents;

4. The double pump system is adopted, and the rotation parameters and feed parameters can be adjusted independently. The combination of variable oil pump and variable oil motor can adjust the speed and torque steplessly in a large range, which improves the adaptability of the drilling rig;

5. The main shaft of the rotator is a through hole structure, and the length of the drill pipe is not limited by the given range of the drill. Taking out the clamp slip can enlarge the diameter of the through hole and facilitate the lifting and lowering of the large diameter drilling tools;

6. Hydraulic components are imported or domestic advanced products with stable performance, strong versatility and reliable quality;

7. Through the control console for centralized operation, personnel can be far away from the orifice for a certain distance, which is conducive to personal safety;

| Drilling depth | 600/100M | Feeding capacity | 160KN |

| Drill pipe diameter | Φ72/Φ89 | Pulling capacity | 240KN |

| Diameter of through hole | Φ | Motor power | 75KW |

| Borehole inclination | 0~±90° | Overall quality | 6800kg |

| Slewing speed | Host quality | ||

| Maximum torque | 6000N.m | Lifting stroke | 600 |

| Walking speed | 1.5Km/h | Max Climb Capability | 25° |

Main Products

Our main products: Mining crawler hydraulic drilling rig, mining anchor cable anchorage, machine tool accessories: spring chuck, milling chuck, drilling chuck, tapping chuck, boring head, mandrel, expansion sleeve, drill connecting rod, tool handle, top, precision flat pliers, etc

Product details

Our workshop

Our Services

1.Your inquiry related to our products or prices will be replied in 24 hours.

2.Well-trained and experienced staffs to answer all your enquires in fluent English.

3.Any of your customized personal needs we will try our best to help you to design and put into product.

4.Strict inspection during the process of manufacturing.

5.Customer satisfaction is our number one priority.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23