2.5t Four Vessels Brewhouse for Large Brewery Beer Kettle

Shenzhen Shiner Packaging Co., Ltd. / 2022-07-05

- After-sales Service:Provide

- Warranty:3 Years

- Condition:New

- Customized:Customized

- Voltage:380V

- Composition:SS304

=== Base Info ===

- Model NO.:ZH-2.5T

- Processing Material:Beer

- Process:Boiling

- Material:SS304

- Tank Thickness:Inner 3mm Outside :2mm

- Temperature Control:Automatic

- Heating:Gas Steam Generator

- Heat Insulation:Rock Wool Th:80-100mm

- Inner Surface:Pickled and Passivation

- Welding:Argon Arc TIG 100%

- Function:Boiling Wort

- Transport Package:Steel Frame or Wooden Case

- Specification:as customer request

- Trademark:Zunhuang

- Origin:China

- Production Capacity:500piece

=== Description ===

Basic Info.

Model NO. ZH-2.5T Processing Material Beer Process Boiling Material SS304 Tank Thickness Inner 3mm Outside :2mm Temperature Control Automatic Heating Gas Steam Generator Heat Insulation Rock Wool Th:80-100mm Inner Surface Pickled and Passivation Welding Argon Arc TIG 100% Function Boiling Wort Transport Package Steel Frame or Wooden Case Specification as customer request Trademark Zunhuang Origin China Production Capacity 500pieceProduct Description

Description:

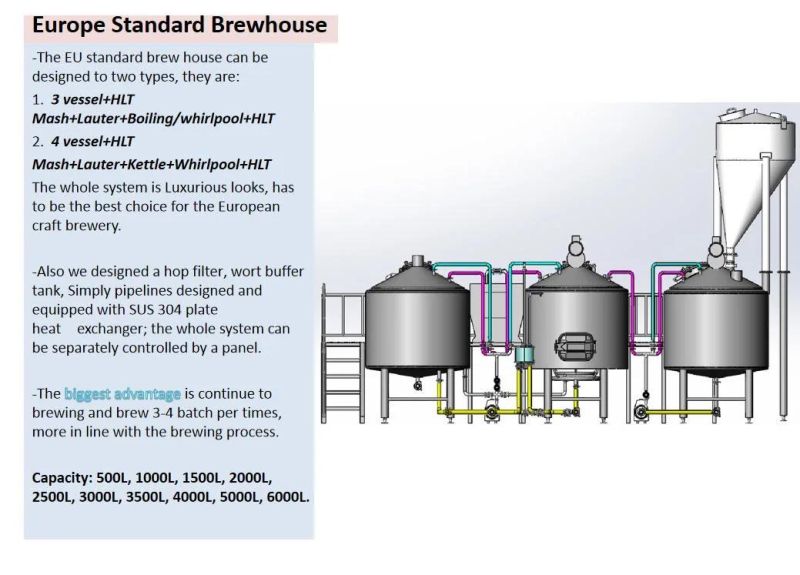

Mash system:

1. Mash tank ,Lauter tank, brew Kettle &Whirlpool tun in various combination Two vessel/Three vessel /Four vessel

2. Hot water tank and cold water tank for optional in special combinations

3. Infusion or decoction brewing methods are designed as request

4. Stainless steel or Red copper are popular

5. Two stages or single stage heat exchanger for wort cooling

6. Completely stainless steel integrated work platform

7. Sanitary and efficiency wort pump

8. All pipings and fittings

brewhouse: mash & lauter, boiling kettle$whirlpool. with hot liquid tank Electric steam boiler

Gas steam generator:

Inner surface pickled and passivation:

Mash &Lauter tun inside:

Fermentation system:

1. Capacity:500L OR 1000l working volume +25% Head space

2. Interior shell thickness 3-6mm, Exterior shell=2mm

3. 100% TIG welding with pure argon gas shield

4. Interior finish: pickled and passivated, external polished, 80mm insulated

5. Test pressure 3 bar, working pressure 1.5 bar

6. Glycol zones (Both on side and concial/bottom)

7. 60°conical bottom for Fermener, Shadow less side man way

8. Racking arm, Sample valve, Pressure relief valve on the top, Dry hopping on the top

9. Mechanical relief valve 3 bar on CIP arm with pressure gauge

10.Adjustable tank leveling pads.

Auxiliary equipment:

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23