Plastic Pipe Machine for PU Insulated Jacket Pipe

=== Base Info ===

=== Description ===

Basic Info.

Model NO. PE-110/600 PE-655/1372 PE-960/1680 Condition New Extruder High-Efficient Output Single Screw Extruder Electrical Elements ABB Inverter, Simens PLC and Contactors Transport Package Standard Package Specification 28m, 32m, 45m Trademark HSD Origin Qingdao, China HS Code 8477209000 Production Capacity 100 Unit/YearProduct Description

Plastic Pipe Machine For PU Insulated Jacket Pipe---Pipe diameter range: 110-600mm, 655-1372mm, 960-1680mm

---The extrusion line comprise equipments and devices as below,

1set Vacuum loader

1set Hopper dryer

1set High-effeciency single screw extruder

1set single screw extruder for mark line

1set Vacuum calibration table

1set Water spraying tank

1 set Hauling machine

1set Cutting machine

1set Stacker

I. Pipe Usage

---HDPE jacket pipe is out case of thermal insulating pipe, which is widely used in central heating, oil, nature gas and other industrial area.

II. Machine Advantages

---High-efficiency extruder gives larger output, stable performance.

For example

SJ-75/33---250-350kg/h

SJ-120/33---700-900kg/h

SJ-150/33---800-1200kg/h

---Compared with inflating method (internal pressure method)

1. For 24 hours working, it reduces 2-3 workers for each shift.

2. There is much waste pipe and material, no need workers to crush waste material.

3. High-effeciency. Take Dimater 960mm as an example, Output is approximately 60 pcs of 11.6meters pipe, it is much higher output than that of inflating method.

4. Pipe wall is average and smooth, to reduce waste of raw material, and pipe thickness is adjustable.

5. No need trim edge, once forming.

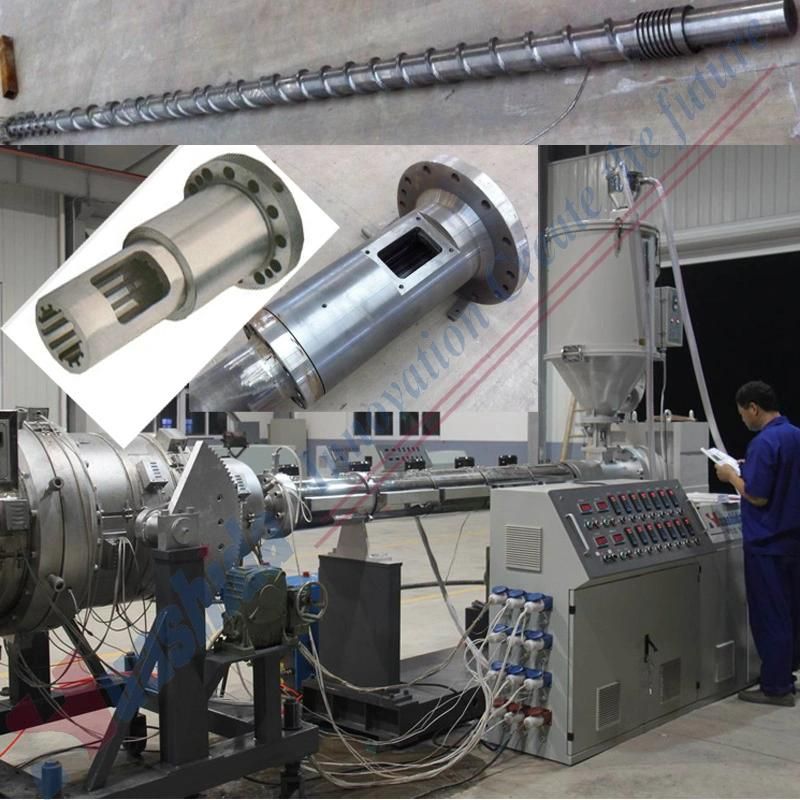

III. Main machine- High-effeciency single screw extruder

---Single screw is with barreir & mixing head; barrel is new model with slotting (channel), Both make security of good jellification, large output and stable performance.

IV. Controlling system

The complete line could be controlled by PLC, with good human-machine interface, all technical parameters could be set and indicated by touching screen. Controlling system is designed according to the customer;s requirement, to be with PLC, or without.

V. Electrical system

---ABB frequency converter or EUROTHERM speed controller

---Japan RKC temperature controller

--- SIEMENS AC contactors

| Style | PE-110-600 | PE-655/1372 | PE-960/1680 | |

| Main extruder | SJ-75/33 | SJ-120/33 | SJ-150/33 | |

| Pipe diameter | Φ110-600mm | Φ 655-1372 mm | Φ 960-1680mm | |

| Capacity | 250-350kg/h | 700~900 kg/h | 800-1200kg/h | |

| Installed power | 160kw | 440 kw | 580kw | |

| Length | 28m | 32 m | 45m |

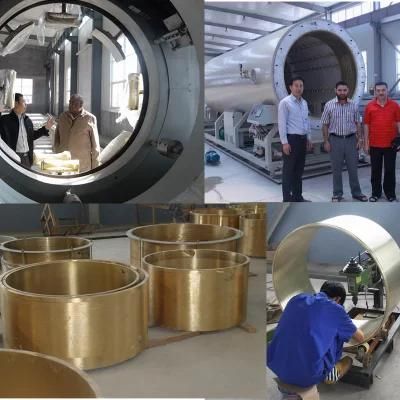

Up to now, We have successfully entered the oversea markets of Russia, Iran, UAE, India, Belarus, Kazakhstan and son on. Our pipeline production line is nearly 50sets at home and abroad.

HUASHIDA Factory located in Qingdao High & New Technology Industrial Area- Qingdao Huashida industrial Park, covers an area of about 4000 square meters. We have obtained more than 10patents and many industry certifications at home and abroad. HUASHIDA company has high qualified and experienced teams for reaching& designing, manufacturing and site operation.

We have reliable products of different models because of our powerful making capacity. We can satisfy our customer's special need because of our outstanding R&D and design capacity. We can offer our user with timely and convenient techniqual support because of our perfect after-sales service.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23