High Capacity Blueberry Jam Processing Line & Machine

Nanjing Lipack Import and Export Co., Ltd. / 2022-07-05

- Type:Turkey Solution Fruit Jam Processing Line

- Voltage:380V

- Power:Depending on The Capacity and Configutation

- Customized:Customized

- Material Capacity:1-65tons,H

- End-Products:Blueberry Jam

=== Base Info ===

- Model NO.:shjump-NJBJ-01

- End-Products Package:Aseptic Bag, Bottle, Tin Cans, Pouch, Pet, etc

- After-Sale Service:Engineers Available to Service Machine Overseas

- Certification:Ce, ISO9001

- Transport Package:Export Standard Wooden Package

- Specification:Stainless Steel 304,316

- Trademark:SHJUMP

- Origin:Shanghai of China

- Production Capacity:20

=== Description ===

Basic Info.

Model NO. shjump-NJBJ-01 End-Products Package Aseptic Bag, Bottle, Tin Cans, Pouch, Pet, etc After-Sale Service Engineers Available to Service Machine Overseas Certification Ce, ISO9001 Transport Package Export Standard Wooden Package Specification Stainless Steel 304/316 Trademark SHJUMP Origin Shanghai of China Production Capacity 20Product Description

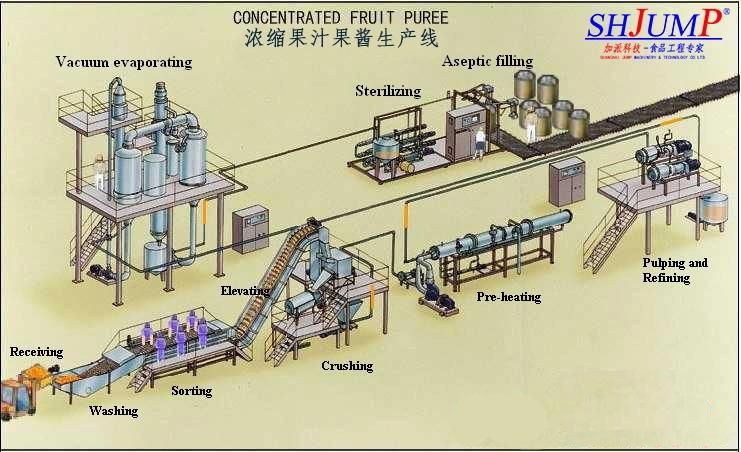

1.PRODUCT DESCRIPTION:1).Receiving system

2).Washing system

3).Elevating system

4).Sorting system.

5.)Curshing section

6).Preheating system

7).Pulping & Refining

8.)Sterilizting section

9) Vaccum evaporating

10.)Filling system.

11)Post sterilization

2.PROCESSING FLOW CHART:

3.MAIN MACHINE DESCRIPTION :

| 1).Bucket Elevator | 1. Smooth bucket structure against clamping fruits, suitable for tomato, strawberry, apple, pear, apricot, etc. 2. Running stably with low noise, speed adjustable by transducer. 3. Anticorrosive bearings, double sides seal. |

| 2).Air Blowing & Washing Machine | 1 Used to wash fresh tomato, strawberry, mango, etc. 2 Special design of surfing and bubbling to ensure a through cleaning and lessening the damage to the fruit as well. 3 Suitable for many kinds of fruit or vegetables, such as tomatoes, strawberry, apple,mango,etc. |

| 3.)Peeling, pulping & Refining Monobloc (Pulper) | 1. The unit can peel, pulp and refine fruits together. 2. The aperture of strainer screen can be adjustable (change) based on customer's requirement. 3. Incorporated Italian technology, high quality stainless steel material in contact with fruit material. |

| 4.)Belt press extractor | 1. Widely used in extracting and dehydrating of many kinds of acinus, pip fruits, and vegetables. 2. the unit adopt advanced technology, big press and high efficiency, high degree of automatic, easy to operate and maintains. 3. the extraction rate can be get 75-85%(based on raw material) 4. low investment and high efficiency |

| 5.)Preheater | 1. To inactivate enzyme and protect color of paste. 2. Auto temperature control and the out temperature are adjustable. 3. Multi-tubular structure with end cover 4. If the effect of preheat and extinguish enzyme failed or not enough, the product flow return to tube again automatically. |

| 6.)Evaporator | 1. Adjustable and contrllable direct contact heat treatment units. 2. Shortest possible residence time, presence of a thin film along the entire length of the tubes reduces holdup and residence time. 3. Special design of liquid distribution systems to ensure correct tube coverage. The feed enters at the top of the calandria where a distributor ensures film formation on the inside surface of each tube. 4. The vapor flow is co-current to the liquid and the vapor drag improves the heat transfer. The vapor and the remaining liquid are separated in a cyclone separator. 5. Efficient design of separators. 6. Multiple effect arrangement provides steam economy. |

| 7.)Tube in tube sterilizer | 1. The united is consisted of product receiving tank, superheated water tank, pumps, product dual filter, tubular superheated water generate system, tube in tube heat exchanger, PLC control system, Control cabinet, steam inlet system, valves and sensors, etc. 2. Incorporated Italian technology and conform to Euro-standard 3. Great heat exchange area, low energy consumption and easy maintenance 4. Adopt mirror welding tech and keep the smooth pipe joint 5. Auto backtrack if not enough sterilization 6. CIP and auto SIP available together with aseptic filler 7. Liquid level and temp controlled on real time |

4. OUR ADVANTAGE:

1.This project is the combination of domestic and foreign advanced technology to the production of fruits and design, and different seasons can produce different fruits.

2. All the equipment in the system are made of stainless steel (directly contact with the raw material ) are the most advanced processing technology as the foundation of modernization. The whole process design and the connection of pipeline are arranged after engineers fine compute, and considering the retention of the original natural aromatic constituents of fruits and vegetables, the cooling ,heating processing and the transmission are finished in a short time and distance, effectively preventing flavor and substances losing in the thermal reaction ; and also reduce the oxidation under high temperature conditions reflect to bring quality damage. The whole production line from fruit crushing material, all in a closed environment, through crushing, water cooking separation, concentration, sterilization, filling and aseptic environment,

maximize the retention of the original flavor and nutritional ingredients.

3.The operation of the control part use the automatic control system, automatic fault alarm system, a full range of security mechanism, security equipment and personnel safety; all electric control system parts were derived from the international well-known brands, such as Siemens, Omron and so on.

4.The types of steam control in production line (extremely important, related to the quality of products) all come from world famous steam control system brand Spirax sarco ,easy control, high reliability, effectively ensuring the quality of different batches of the product pure and the balance.

5.The main equipment are from Shanghai JUMP Machinery & Technology Co., Ltd.to ensure the equipment reliability, controllable ; the accuracy of the parameters; stability and safety.

We can suggest customer the most suitable machine according to their formula and Raw material. "Design and development", "manufacturing", "installation and commissioning", "technical training" and "after sales service". We can introduce you supplier of raw material, bottles, labels etc. Welcome you to our production workshop to learn how our engineer produce. We could customize machines according to your real need, and we could send our engineer to your factory to install machines and train your worker of Operation and maintenance.

Packaging Details:

1. Stable wooden package protects machine from strike and damage.

2. Wound plastic film keeps machine out of damp and corrosion.

3. Fumigation-free package helps the smooth customs clearance.

4. The big size machine will be fixed in container without package.

Delivery Detail:

Date of delivery: in 90 working days after the date of the order.

Date of Installation and commissioning: in 30 working days after the factory is in place.

5. Factory site & Sales office

6. SHJUMP projects

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23