Lab Twin Screw Extruder with Air Cooling

Dongguan Koves Precision Tools Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Main Features

1) Adopting international brand variable speed control motor to precisely control the screw rotating speed;

2) The 3D processed geometry screw elements maintain uniform gaps and achieve very good self-clean and precise plasticizing effect;

3) Using parallel two-axis high speed high torque gearbox to make the extruder applicable for more than 95% materials' compounding and extrusion technologies;

4) Emergency stops and devices to protect safety of the operator;

5) Optional side feeder for special materials, e.g. glass fiber;

6) Optional forced feeder to increase stability of feeding;

7) Optional liquid feeding equipment;

8) Optional gravimetric feeder

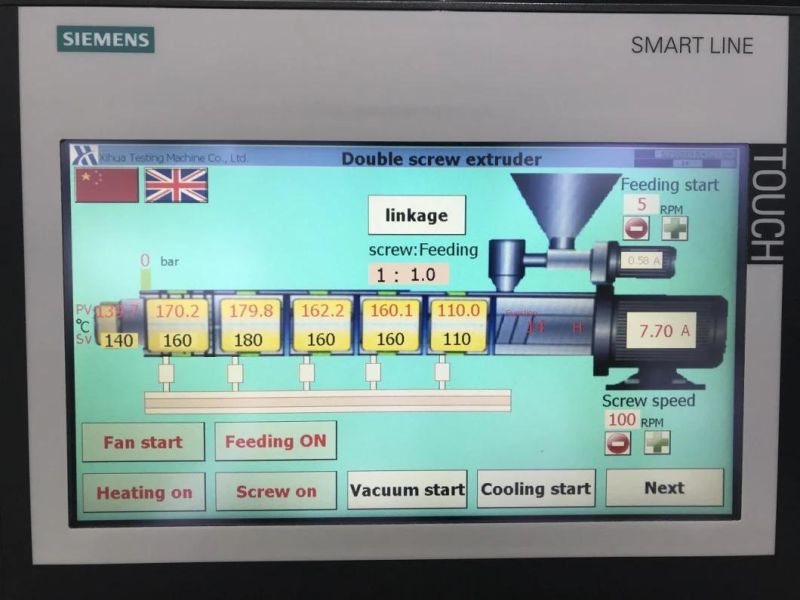

Detail images

Testing sample

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23