50% Energy-Saving Stepless Dimming UV Curing Machine for Automatic Printing

Shenzhen Tamprinter Printing Machinery Co., Ltd. / 2022-06-27

- After-sales Service:1

- Warranty:1

- Type:Printing Unit Glazing

- Form:Printing Machine Online Glazing Unit

- Coating Paint:Light Curing Type Coating

- Coated Glazing Type:Printed Coated Glazing

=== Base Info ===

- Model NO.:TM-UV-kit1200

- Glazing Product:Part Glazing

- Application:Paper Printed, Paperboard

- Tile Type:Steel

- Input Mode:Automatic

- Transport Package:Plywood

- Specification:4150*1592*1721MM , 11.37CBM 1890 * 1430 * 1402MM ,

- Trademark:TAMPRINTER

- Origin:China

- HS Code:8543709990

- Production Capacity:10set,Month

=== Description === 5%~100% Stepless Stacker parameters

item parameter Paper size 71*102cm

Specification Product description

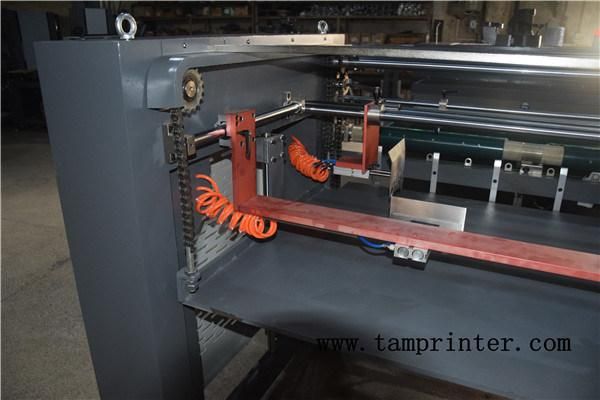

[Abstract] This utility model is a stepless dimming UV varnish curing machine with automatic paper delivery machine, designed for the UV curing field of the offset printing industry, and its structure includes a conveying mechanism for conveying the paper to be cured and a conveying mechanism The upper curing chamber is equipped with an ultraviolet light source for curing the UV varnish on the sheet to be cured on the conveying mechanism, and also includes an electronic power control module, and the stepless dimming control module is electrically connected to the ultraviolet light source. , The stepless dimming control module can gradually control the irradiation intensity of the ultraviolet light source. Compared with the existing rectifier+capacitor technology, the light irradiation intensity of the ultraviolet light source of the present invention can be gradually adjusted by the control module. Therefore, according to the needs of the cured product, the light irradiation intensity can be adjusted to a suitable intensity to meet the curing light intensity. It also avoids energy waste caused by excessive irradiation intensity, so the scope of application is wider. When there is no paper output from the offset printing machine, the infrared detection system of the UV machine sends a signal to the electronic power control system, the light is dimmed, the belt stops, the top alarm light is on, and the buzzer sounds. The take-up machine stops.

The automatic paper receiver is also called a sheet stacker, which collects paper synchronously according to the speed of the UV machine. Each time a piece of paper is received, the pallet is lowered by one paper thickness until the carriage reaches the ground, the machine is suspended, and the forklift replaces the pallet.

Stepless dimming offset printing UV curing machine with automatic stacker

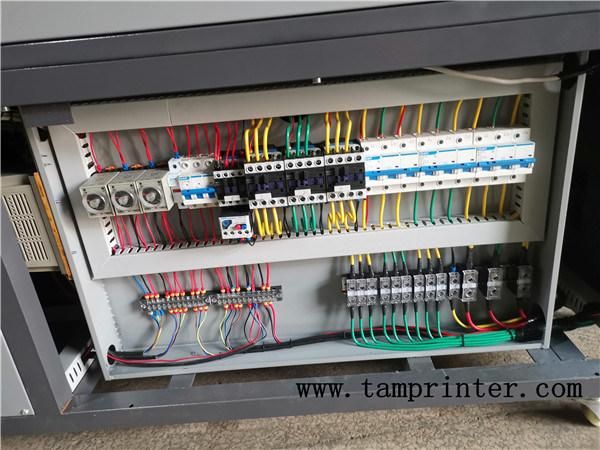

Control panel operation introduction:

- -----Total power indicator.

- -----Power switch.

- -----Conveyor switch.

- -----UV1 light switch.

- -----UV1 light intensity and adjustable switch.

- -----UV2 light switch.

- -----UV2 light intensity and adjustable switch.

- -----UV3 light switch.

- -----UV3 light intensity and adjustable switch.

- ----Power outlet.

- ----Conveyor indicator light.

- ----Exhaust fan switch.

- ---- Conveyor speed adjustment switch.

- -----Conveyor stop switch

Instructions:

1. Connect the power supply (220V / 3P) first. 3 wires marked "L" is live connected to FireWire, 1 wire marked "N" is Neutral connected to zero. 1 wire marked "PE" is Earth ground wire. After connecting the power supply, turn on the main power switch of "2" key Turn from left to right), the power indicator "1" will light up.

FAQ

Q1:

¿Por qué la potencia es de 25KW?

A1:

No vi su dispositivo y no conozco el tamaño del papel original, el siguiente es nuestro análisis

∵

Máquina nueva tamaño de papel 24"*36" velocidad 4500 hojas por hora = {(24 pulgadas*25,4) mm+espacio papel a papel 100 mm}X4500 hojas/60 minutos = 53 metros/minutos

Adivina el tamaño de papel de la máquina antigua 18"*27" velocidad 4500 hojas por hora = {(18*25,4) + 75}X4500/60 =40 metros/minutos

∴

36 pulgadas/27 pulgadas = 8 kw/5,6 kw

24 pulgadas/18 pulgadas = 3 lámparas/2 lámparas,

53/40 (m/min)=3 lámparas/2 lámparas,

∴

Nueva máquina 3 piezas * 8kw + motor de correa + ventiladores = 25kw

Q2:

¿Por qué comprar un apilador?

A2:

El costo de este apilador es solo el 0,5% de la máquina de impresión offset,

Puede ahorrar el salario de un trabajador, que solo equivale a medio año de salario de un trabajador,

y no cansado,

no rescindirá el contrato.

Calificado y estable que los trabajadores.

Q3:

Las cosas buenas son demasiado caras, si no tienes suficiente presupuesto, ¿cómo hacerlo?

A3:

El costo de este equipo es solo el 5% de la máquina de impresión offset,

un buen caballo con una buena montura.

Esto le dará a sus clientes una impresión de alto nivel,

lo más importante es reducir los costes laborales,

reducir la tasa de defectos,

tan fácil de vencer a los competidores sin importar el precio o la calidad,

ganar la confianza de los clientes,

luego tener más pedidos.

Solo agregar la confianza de un cliente es suficiente para superar el valor del costo de las máquinas.

más preguntas, por favor háganoslo saber

Payment Terms TT/LC

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23