ABA Double Screws Double Head Dies Co-Extrusion High Speed Film Making Machine

Nanyang Yukang Photonics Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. SJ- Computerized Computerized Machine Weight 1.2 T Certification CE, ISO9001:2008 Die Type Rotary Die Winder Type Single Winder Screw L/D 28:1 Transport Package Simple Packing Specification CE, ISO Trademark YUNBANG Origin Zhejiang China HS Code 84773000 Production Capacity 120kg/HProduct Description

Product DescriptionFilm Blowing Machine applicationThis Film Blowing Machine is used for blowing the various kinds film of HDPE, LDPE, LLDPE etc, referred as to low density polyethylene (LDPE), high density polyethylene(HDPE)and linear low density polyethylene(LLDPE) etc, which are widely used for printing, agricultural,packing industrial, garments , textile, and making plastic bags, like T-shirt bag, flat bag, and other daily usage bag, etc.

1. Blowing film can be used either in tube form (e.g. for plastic bags and sacks) or the tube can be slit to form a sheet. Blown film extrusion can be used for the manufacture of co-extruded, double-layer or multi-layer films for high barrier applications such as food packaging.

2. Industry packaging (e.g. shrinkable film, stretch film, bag film or container liners).

3. Agricultural film (e.g. greenhouse film, crop forcing film, silage film, silage stretch film).

4.Consumer packaging (e.g. packaging film for frozen products, shrinkable film for transport packaging, food wrap film, packaging bags, or form, fill and seal packaging film).

5. Barrier film (e.g. film made of raw materials such as polyamides and EVOH acting as an aroma or oxygen barrier used for packaging food, e. g. cold meats and cheese), films for the packaging of medical products.

6.Laminating film (e.g. laminating of aluminum or paper used for packaging for example milk or coffee).

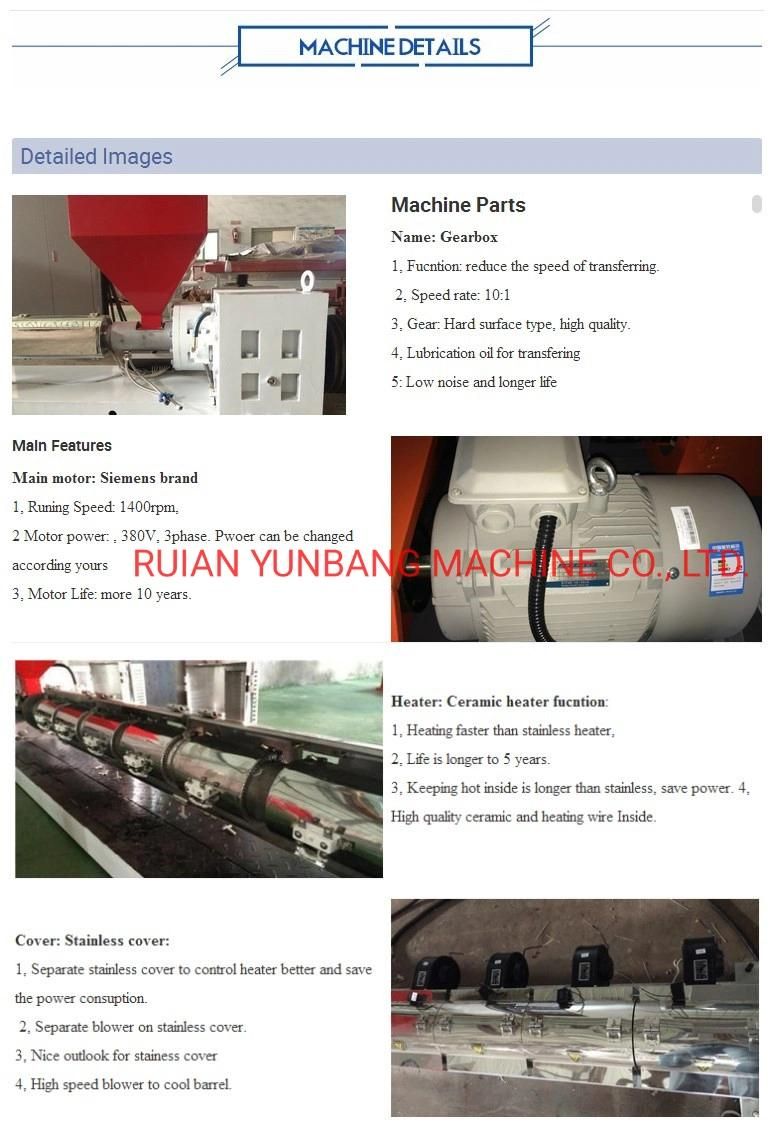

Film Blowing Machine features

1. Main motor and take-up motor are controlled by frequency inverter adjustment.

2. Material of screw and barrel: 38CrMoAlA Polished with Nitride Treatment

Hardness of heat treatment: Screw HV≥ 740, barrel HV≥ 900

Depth of hardening: 0.6-0.7mm

Brittleness grade: ≤ 2 grade

3. Gear box: 250 Involutes cylinder Bevel wheel, cast alloy steel piston, fine grinding hard gear surface

4. Die material: Steel 45#/surface treatment of flow channel: Hard chrome- plating

5. Double digital display temperature controller

Film Blowing Machine advantages

1.Outstanding film blowing machine's gearbox, motor, extruder and controller.

2.Barrel and screw of film blowing machine is finished by accurate machining and special nitrogen treatment.

3.Main motor of film blowing machine is driven by controller with frequency changer.

4.High efficiency air infusing cooler to keep the high output.

5.Winding unit or tandem winder position can be adjusted freely.

6. All machines will be examined and tested before delivery .

7.After-sale service, we had been continually dispatching our own experienced technicians abroad monthly.

8.Highlighted properties of the blown film, such as tensile strength, flexural strength, durability and toughness.

Blowing film typically feature a much better equilibrium of mechanical properties than cast or extruded films since it is drawn both the transverse and also linear direction. Mechanical properties of the film consist of tensile, flexural toughness and strength. The virtually consistent commercial properties in both orientations to enable optimum strength in the film.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23