High Output Waste Plastic Recycling Extruder Straps Band Making Machine

Ningbo Herovas Electronics Technology Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

the specification of pp strap manufacturing machine

Engine

Main performance parameters

The parameters of PP strap 12006

Main Features

1) The pp strap manufacturing machine making the operation more easy and lower request;

2) Reciprocating super-long distance low-temperature stretching, great stretching times, good rigidity of finished band;

3) Light heat setting unit, differential speed traction design, internal stress may be removed to the maximum extent;

4) Organic combination of the 3rd stretching unit and embossing mechanism, scientific structure, advanced configuration;

5) Self-circulating wind heat warming system of the pp strap manufacturing machine, energy saving ;

6) High-accuracy good-quality screw, large extrusion capacity, constant extrusion pressure.

Certifications

Our service

After-sales service

1.We provide one-year warranty guarantee for all the machines. We supply long term spare parts for every customer and 24 hours technical support by email, calling and door to door service;

2.We run machines in our factory before delivery. Clients check machines running in our factory, and when machines arrive in Client's factory, we will arrange our engineer for you to run machines in client's factory too.

3.We provide service manual and maintenance instruction of main electric appliance,usage manual of equipment.

4.We also supply installation drawing of water, electricity, gas of equipment.

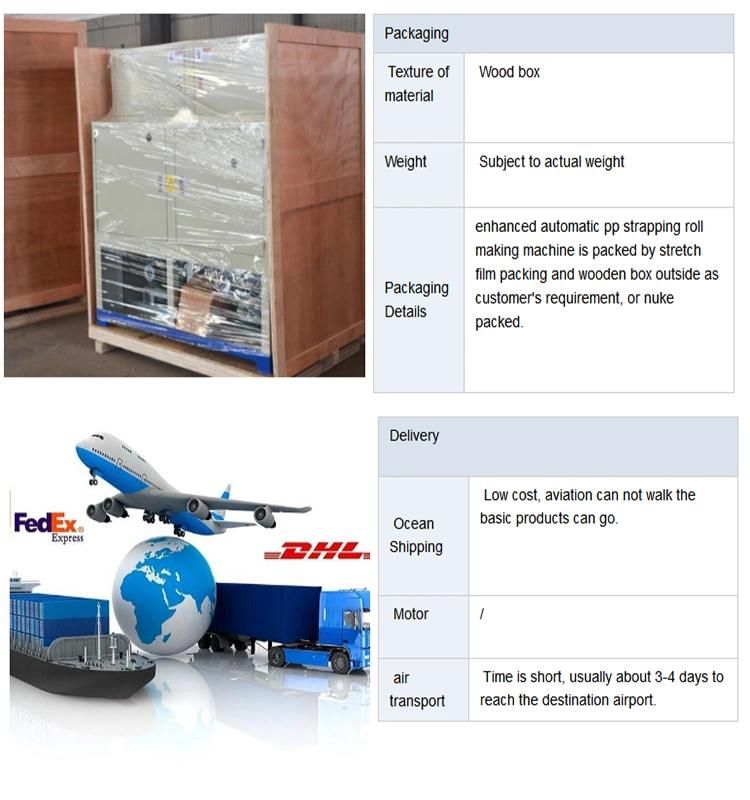

Shipping&delivery

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23