Best Quality PVC Four Cavity Pipe Extrusion Machine

Ningbo Conwhole Hardware Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

PVC four pipe extrusion production line

Equipment list of the 4 PVC pipe production line:

| NO. | Equipment Name | Description | machinery photos |

| 1 | SJSZ65/132 conical twin screw extruder | Unique screw design, short plasticizing time, good compounding and plasticizing effect. |  |

| 2 | molds for 16-32mm(4 cavity) | Four even flow channel with chrome plated, pressure of four channels are stable, final product size stable. |  |

| 3 | Four cavities water cooling tank | Made of stainless steel, vacuum forming and water cooling |  |

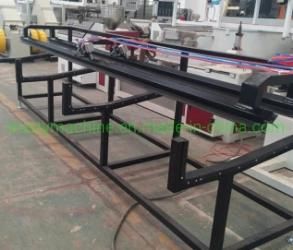

| 4 | Four caivites puller | Four individual pullers, it is easy to operate and adjust machine. |  |

| 5 | Four cavities cutter | no chip cut, high accuracy |  |

| 6 | stacker | 1set |  |

AFTER SERVICE

| Technical documentation |

| All symbols on the equipment will be in English. We will be responsible for providing the Buyer with a general layout plan, electrical plan, installation orientation and manuals, in English. |

| Arrangements for inspection, installation and testing of the equipment |

| a. After all of the equipment is delivered to the customer's factory, the Buyer shall be responsible for all preparation work, e.g. electricity supply, water supply, cranes and labor, etc. b. We will prepare visa applications for their engineers, who will assist in the equipment installation and testing at the Buyer's factory. c. The Buyer will buy a round-trip air ticket for the engineer(s) after the visa application is approved. The Buyer is responsible for all expenses generated, e.g. visa application fees, meals, accommodation and an allowance of $80.00 per day for each engineer. d. The engineer(s) will provide free training for the operators and maintenance people, in Buyer's factory. e. If the Buyer does not request commissioning by our engineer(s) within four months from the date of the bill of lading, it will be accepted that all the equipment has been successfully tested and approved by the Buyer. |

| Quantity and quality guarantee |

| a. In cases of quantity discrepancies or equipment damage, at the destination, the Buyer will file a claim within 30 days after the arrival of the goods at its destination. The insurance company and the shipping company will be responsible for all discrepancies and damage caused by the shipping company or other transportation companies. b. Guarantee period and after-sales services: 13 months from the date of the bill of lading. During this guarantee period, if there is a quality issue, we will provide spare parts without charge. If malfunctions are caused by the Buyer's improper operation of equipment, we will provide the Buyer with spare parts at cost prices. c. Long-term service: Beyond one year, we will provide the Buyer with spare parts at reasonable prices and provide long-term technical guidance. |

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23