Vegetable Processing Line Frozen Peas Production Line

Wuxi Xinrun Protective Film Co., Ltd. / 2022-07-05

- After-sales Service:Door to Door or Video

- Warranty:1year

- Certification:CE, ISO9001, SGS

- Power Source:Electric

- Process:Thermal Processing

- Automatic Grade:Automatic

=== Base Info ===

- Model NO.:TS

- Application:Chips, Pea

- Customized:Customized

- Material:Food Grade Stainless Steel

- Frying Temperature:0-300 Degrees Celsius

- Fried Time:2min

- Automatic:Full

- Transport Package:According to Customer Requirement

- Specification:Customized

- Trademark:Ambitious

- Origin:China

- HS Code:8438600000

- Production Capacity:10sets,Year

=== Description ===

Basic Info.

Model NO. TS Application Chips, Pea Customized Customized Material Food Grade Stainless Steel Frying Temperature 0-300 Degrees Celsius Fried Time 2min Automatic Full Transport Package According to Customer Requirement Specification Customized Trademark Ambitious Origin China HS Code 8438600000 Production Capacity 10sets/YearProduct Description

Peas Production Line

1.-Full Automatic Peas Production Line

The peas production line is an advanced snack food processing equipment. It integrates

the advantages of all kinds of individual machines. It is easy to be operated, powerful and

investment saving.

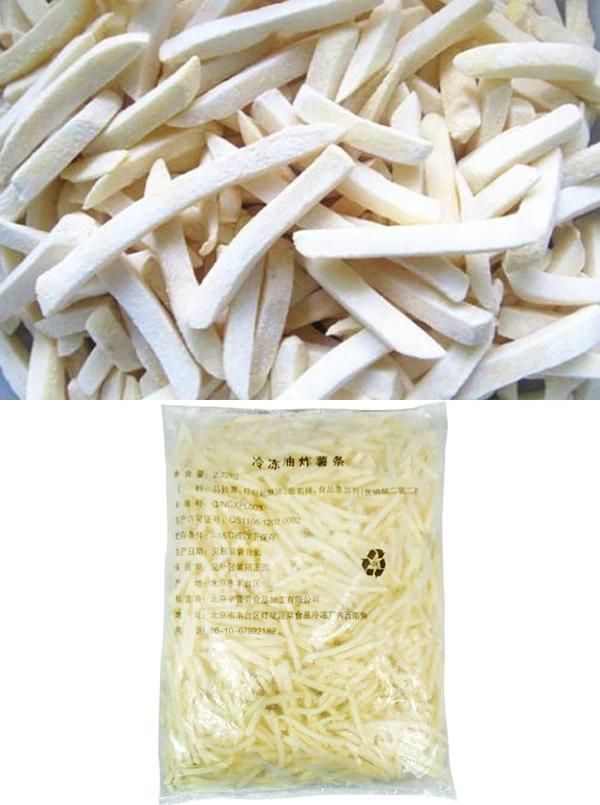

Main processing of the french fries:

1) Soaking: The first stage of the production is soaking,to make peas become soft

2) Washing: Washed the pea after soaking

3) Blanching&Cooling: After washing,the peas are transfered into blanching machine for

blanching,for color pretection,after this,into the cold water tank for cooling.

4) Drying: Cold air drying machine works this process,to remove most water on the surface of the

peas.Keep the product dry is necessary before freezing.

5) Freezing: After blanched from the continous cooling machine, the peas get into the freezing machine for quick freezed, then transfered into the cold storage.

2.-Applications of peas Manufacturing

Mainly for frozen french fries, frozen vegetables, peas, and so on.

3.-Details of Full Automatic Frozen Production Line

Output | 500kgs/hr | 1000kgs/hr |

Factory Layout(Min) | 600m2, length 50m | 800m2, length 70m |

Electric Required | 29KW | 34KW |

Gas Required | 11m3 /hr | 16m3 /hr |

Edible Oil Required | 550L/lot | 830L/lot |

Labor Required | 5 | 8 |

Raw Material | 1000kgs | 2000kgs |

4.-Package & Shipment

A).Packing:With wrapped film, or in wooden case.

B).Transportation: Shipping, train, or other types.

5.-Company Summary

Zhucheng Tianshun Machinery Co.,Ltd. has grown into a large, specialized food machinery manufacturing enterprise which integrates R & D and manufacturing. Currently has more than 100 employees, the division of labor is professionalization and specific, there are technical department, after-sales service department, domestic marketing department, international business department, etc. The company has all kinds of welding equipment, machining equipment to meet the needs of different customers.

Main products: Food machinery and complete production lines, including: Vegetables&fruits cutting machines,

Peeling&washing machines,

Frying equipment,

Air drying machinery,

Blanching&cooking machine,

Food flavoring machine,

Food coating machine,

Vacuum packing machine,

Complete production line.

All of them can be designed semi-automatic and full automatic, and widely used for processing varieties of vegetable, fruits, fish, seafood, etc. Some of them have pass the CE certificate. All of them could be customized, and we also provide and design individual machines for customers.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23